Process of making cardboard and recycling it

How is cardboard made? In this page I will introduce you about the process of making

and recycling it.

Before explanation, I will show you the name of the part of cardboard.

The wavy paper in the cardboard is called Corrugating medium, and the two flat cardboard are called liner. Both parts are made from recycled paper. When it is recycled, we do not have to separate them.

Many people know “both-side cardboard” (DBLW),which has two liners, however, there are “single-faced cardboard”, which has only one liner, and it has suppleness, so it is used for covering glass bottle like wine.

To be stronger, there are double wall corrugated fiberboard which has one more corrugating medium and liner.

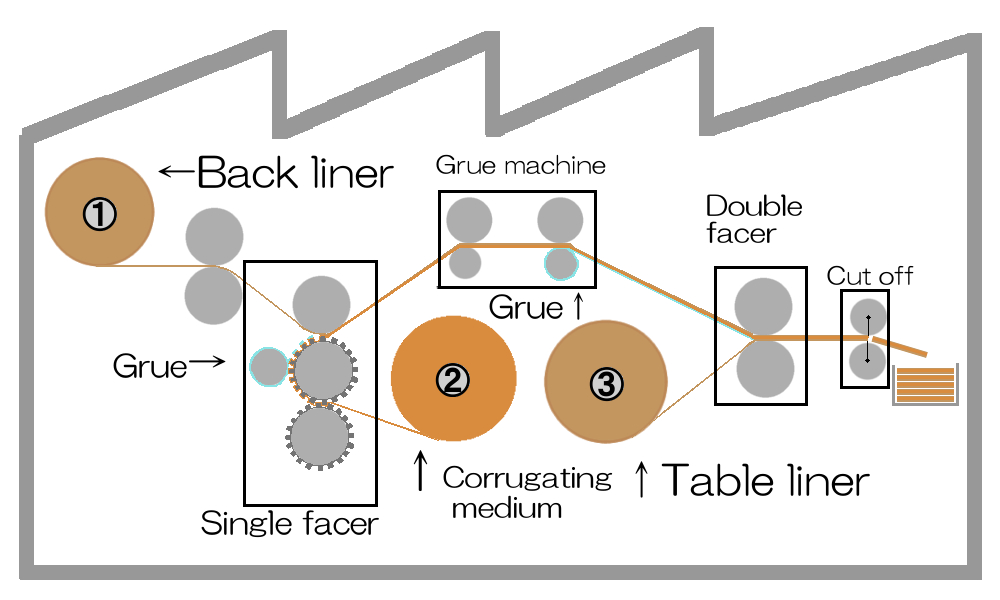

This picture shows the process of making double wall corrugated fiberboard.

1. the back liner

2. corrugating medium

3. the front liner

This is order.

First, the back liner is pulled from the drum 1 (it has only back liner).

Second, the flat corrugating medium is pulled from the drum 2 and goes through the gear to be bumpy.

Third, it goes through the roller to catch the glue and stick with the back liner.

The process so far is called single facer.

The single-faced cardboard which has the back liner and corrugating medium goes through the glue machine to stick with the front liner, and it gets the front liner comes from drum 3. The machine doing this is called double facer.

The cardboard which went through the machine is cut the good size and is sent to the factor making boxes and printing .

GPIレンゴー | 段ボールおもしろブック / 段ボールができるまで

Before explanation, I will show you the name of the part of cardboard.

The wavy paper in the cardboard is called Corrugating medium, and the two flat cardboard are called liner. Both parts are made from recycled paper. When it is recycled, we do not have to separate them.

Many people know “both-side cardboard” (DBLW),which has two liners, however, there are “single-faced cardboard”, which has only one liner, and it has suppleness, so it is used for covering glass bottle like wine.

To be stronger, there are double wall corrugated fiberboard which has one more corrugating medium and liner.

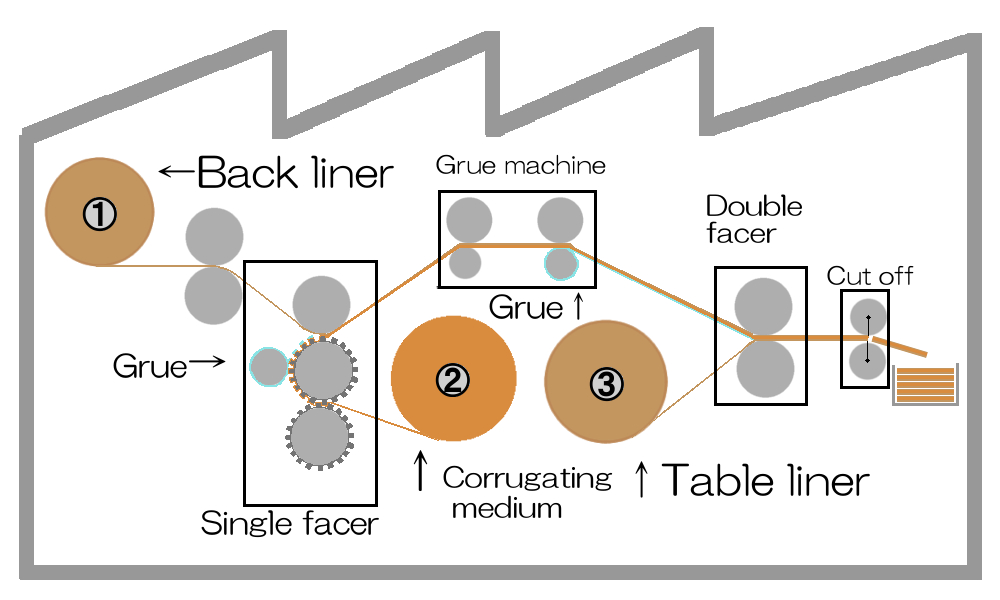

This picture shows the process of making double wall corrugated fiberboard.

1. the back liner

2. corrugating medium

3. the front liner

This is order.

First, the back liner is pulled from the drum 1 (it has only back liner).

Second, the flat corrugating medium is pulled from the drum 2 and goes through the gear to be bumpy.

Third, it goes through the roller to catch the glue and stick with the back liner.

The process so far is called single facer.

The single-faced cardboard which has the back liner and corrugating medium goes through the glue machine to stick with the front liner, and it gets the front liner comes from drum 3. The machine doing this is called double facer.

The cardboard which went through the machine is cut the good size and is sent to the factor making boxes and printing .

GPIレンゴー | 段ボールおもしろブック / 段ボールができるまで