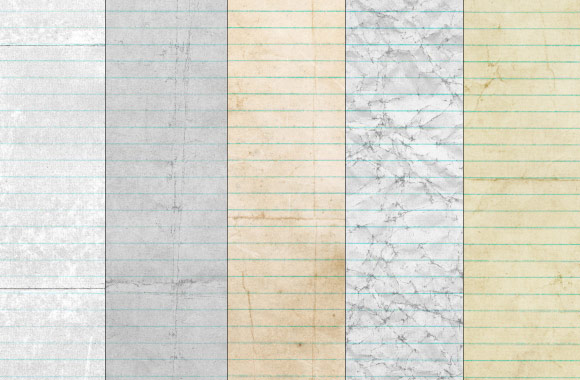

The special quality of the paper

It's the paper used close, but there is a special quality of much everyone doesn't know, so I'd like to introduce by this

page.

・Paper front and back

There are a face where I touch a part of a mesh as a wire in the paper manufacturing process (the back) and a face I don't touch (table). The feel in the surface changes with this at a front and back, and when printing, it has a few influence. Such as it's shown into a wire of both sides and it's reinforced directly in paper after completion to lose a paper front and back present again, a front and back do, and are frightful, it becomes difficult to understand.

・ Paper eye

I think the person who has torn newspaper up knows that there are a direction a newspaper is easy to break where and a direction difficult to break. But do you know why there is difference in easiness of breaking it? When saying in a word, when making paper, this is made. Pulp is jetted from a thin spout at the first stage of the paper manufacturing process. The direction of the paper fiber becomes fixed then. → Clicks this for the person who would like to know about more paper eyes conversantly!

・The paper shelf stability is good.

The paper life is 100, the Japanese paper is said to be 1000 in general. Then, when I say whether it's partial to here by paper and Japanese paper, why is "acid paper" and is because Japanese paper is "neutral paper? Something as the size pill was used, but to prevent a spread by paper I just took the size pill using filter alum before. A cause of the filter alum has taken years off the life of paper. When filter alum is left long, it changes into sulfuric acid, and the paper is made ragged. The way which doesn't use filter alum for the size pill current as of free is also developed, and almost all acidity paper problems is settled. Paper isn't using the one which becomes acidity by the size pill, so Japanese paper becomes neutral. →Clicks this for the person who would like to know about more sulfuric acid paper conversantly!

・Paper front and back

There are a face where I touch a part of a mesh as a wire in the paper manufacturing process (the back) and a face I don't touch (table). The feel in the surface changes with this at a front and back, and when printing, it has a few influence. Such as it's shown into a wire of both sides and it's reinforced directly in paper after completion to lose a paper front and back present again, a front and back do, and are frightful, it becomes difficult to understand.

・ Paper eye

I think the person who has torn newspaper up knows that there are a direction a newspaper is easy to break where and a direction difficult to break. But do you know why there is difference in easiness of breaking it? When saying in a word, when making paper, this is made. Pulp is jetted from a thin spout at the first stage of the paper manufacturing process. The direction of the paper fiber becomes fixed then. → Clicks this for the person who would like to know about more paper eyes conversantly!

・The paper shelf stability is good.

The paper life is 100, the Japanese paper is said to be 1000 in general. Then, when I say whether it's partial to here by paper and Japanese paper, why is "acid paper" and is because Japanese paper is "neutral paper? Something as the size pill was used, but to prevent a spread by paper I just took the size pill using filter alum before. A cause of the filter alum has taken years off the life of paper. When filter alum is left long, it changes into sulfuric acid, and the paper is made ragged. The way which doesn't use filter alum for the size pill current as of free is also developed, and almost all acidity paper problems is settled. Paper isn't using the one which becomes acidity by the size pill, so Japanese paper becomes neutral. →Clicks this for the person who would like to know about more sulfuric acid paper conversantly!