Euglena Plastic

Advantages of Bioplastics

Ordinary plastics made from petroleum are made by refining naphtha from crude oil, pyrolytically decomposing it to produce ethylene, polypropylene, benzene, and other monomers, and then polymerizing them under high temperature and pressure to form polymers. A large amount of fossil fuel is used not only as the raw material but also to produce the high temperature and high-pressure environment, resulting in a large amount of carbon dioxide emissions. This is not ideal from the viewpoint of global warming countermeasures. In addition, petroleum is a limited resource, and if we continue to use it at this rate, it is believed to be depleted in the future.

In contrast, with bioplastics, the carbon dioxide emitted during combustion is offset by the carbon dioxide absorbed from the atmosphere during the growth process of the raw material. In addition, no dioxin is emitted during combustion, and the material can be burned at low temperatures. There is no need to worry about the depletion of raw material resources.

Production of Euglena Plastic

The euglena plastic being developed uses paramylon, a substance stored in euglena, as its main raw material. It is manufactured by reacting β-1,3-glucan, which is produced by decomposing paramylon, with long-chain fatty acids, which are produced by hydrolyzing wax esters made from euglena, to produce plastic with the structure of long-chain alkyl group/acetyl group-incorporated paramylon.

Differences from Ordinary Bioplastics

As ordinary bioplastics made from corn and other crops become more widespread and their production expands, problems similar to the one described in the biofuel page are arising.

Previously, dent corn, a variety of corn grown for animal feed, was used as the raw material for bioplastics instead of food-grade corn. This is because if food corn is used as the raw material, the market price of food corn will increase due to the growing demand for bioplastics, and the corn may not be available to people who need it as food. However, there are concerns that if the production of bioplastics continues to expand, even the feed market, which is relatively large, will be affected.

To avoid such problems, some research is being done to make bioplastics from cellulose and hemicellulose, however, these technologies require difficult processing.

In contrast, euglena plastic has no of the above-mentioned problems, and its relatively high production efficiency has attracted much interest.

Biodegradable Plastic

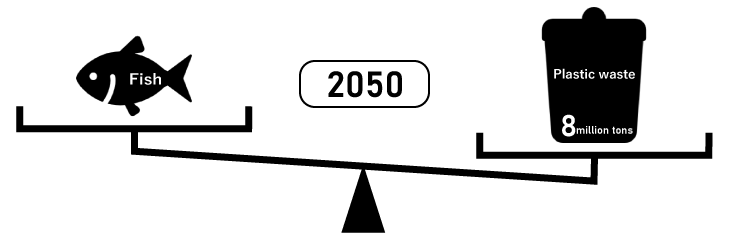

In recent years, the problem of plastic in the oceans has become more serious, and we hear more and more about this topic. Most plastics are not decomposed in nature, and if not burned, they remain almost forever. It is estimated that there are at least 8 million tons of plastic waste in the world and if the amount continues to increase, it is predicted to be more than the amount of fish by 2050.

Some of these plastic wastes become brittle when exposed to UV light and break down into pieces and drift around in the ocean, which are called microplastics. Some of these plastic wastes carry harmful substances such as environmental hormones, which are said to have a great impact on ecosystems and have adverse effects on the human body when people eat fish that have eaten them.

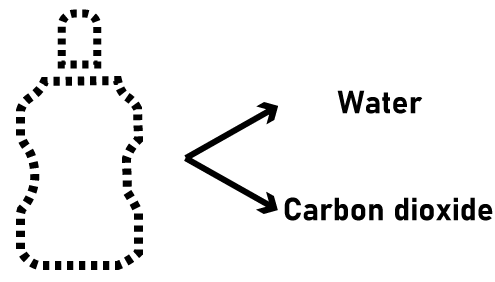

One of the solutions to such problems is the use of biodegradable plastics. Biodegradable plastics have the characteristic that they are decomposed by microorganisms into water and carbon dioxide in the end. Also, the carbon dioxide emitted during the decomposition of biodegradable bioplastics is absorbed from the atmosphere during production, so there is no increase or decrease in carbon dioxide when viewed in total.

In addition, biodegradable plastics are easier to produce from bio-based materials than from petroleum-based materials, and the use of biodegradable bioplastics is expected to increase.

The technology to produce biodegradable plastic from cellulose and starch, which are glucans, the same as the raw material paramylon, has already been established. It is believed that it is possible to develop biodegradable plastic derived from euglena.

Spread and Current Status of Euglena Plastics

Features of Euglena Plastic

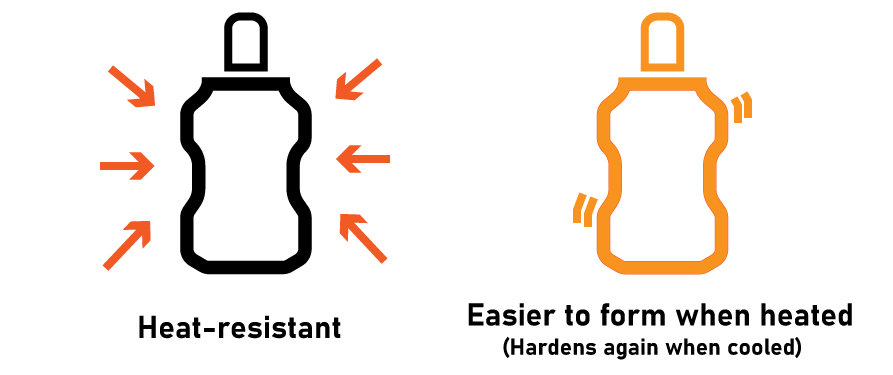

For euglena plastic to become widely used, it must have " advantages" such as price and physical properties. Euglena plastic has a lower impact resistance and bending strength than other plastics. However, its heat resistance is higher than ABS resin, polylactic acid, and nylon 11, and it has excellent thermoplasticity, which affects the ease of molding.

For these reasons, some experts are looking at euglena plastic as a material for laptop computers}and smartphones, which generate heat at high temperatures, or as a protective film for LCD panels.

Current Status of Dissemination

Research and development for practical use is underway.

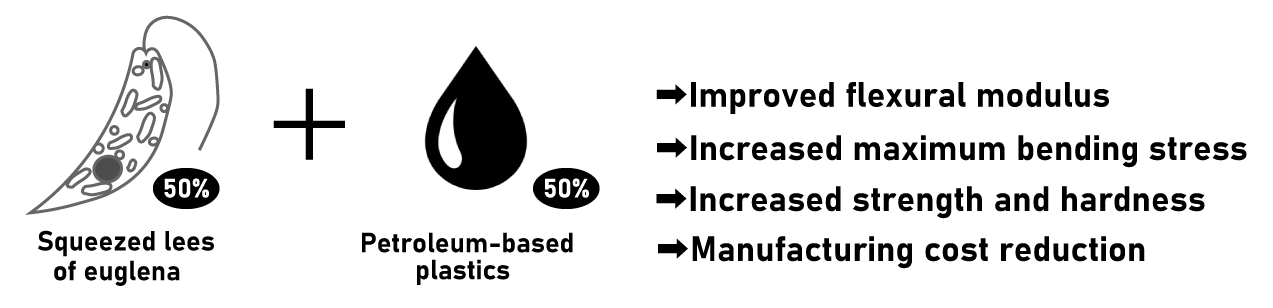

In August 2020, Euglena, which is engaged in various businesses using euglena, announced that it had developed a composite material made from "squeezed waste" after squeezing oil from euglena in order to produce biofuel. This composite material is made from a 50-50 mix of euglena remnants and petroleum-derived polypropylene. By using this composite material, the amount of petroleum-derived plastic can be cut in half by simple calculation. It also has a higher flexural modulus and maximum flexural stress than normal 100% polypropylene, making it superior in both strength and hardness. Also, the production cost can be reduced by using biofuel "squeezed waste".

On July 1, 2020, plastic bags will be charged for in Japan. Plastic bags containing 25% or more of biomass material are exempted from the charge, and this kind of policy support for bioplastics by the government and other organizations will also support the spread of bioplastics, including euglena plastic.

In September 2020, Professor Masahiro Hayashi (Applied Microbiology), Faculty of Agriculture, University of Miyazaki, established a technology to produce "paramylon nanofibers" (PNF) from euglena. Nanofibers are fibrous materials with a diameter of 1nm (nanometer) to 100nm and a length of more than 100 times the diameter and are characterized by the ability to control the gaps between fibers with high precision. He says it can be used for diapers, masks, filters, etc.

Professor Hayashi was the first person in the world to cultivate euglena on an industrial level and put it to practical use as a product. He has established a technology that enables large-scale cultivation without relying on photosynthesis by feeding euglena with glucose. SUBARU, a paper processing company in Aichi Prefecture, will start operating a demonstration plant for this technology in FY2020, and full-scale production is expected to begin in FY2021.

The Future of Euglena Plastic

Various applications of euglena plastic are being considered, and there are actually moves toward development and practical application. However, it is inferior to petroleum-based plastics in terms of price. How can these weaknesses of euglena plastic be resolved?

While some say that it will be difficult to spread the use of plastics, other experts argue that plastics are a "material" and a durable product, and that the criteria for determining value are different from biofuels. They argue that the price difference can be offset by the environmental friendliness of the material, and that it is important for the government to support and promote the use of such plastic.

This site is participating in the 23nd Japan Junior high school/high school Web contest(第23回全国中学高校Webコンテスト).