Ajinomoto Frozen Food Co.

This page introduces the appeal of modern frozen foods, based on an interview with Ajinomoto Frozen Foods Co. (FFA: Fresh Frozen Ajinomoto)

Date of interview (date of response): October 13, 2021

(From Ajinomoto Frozen Foods Co.)

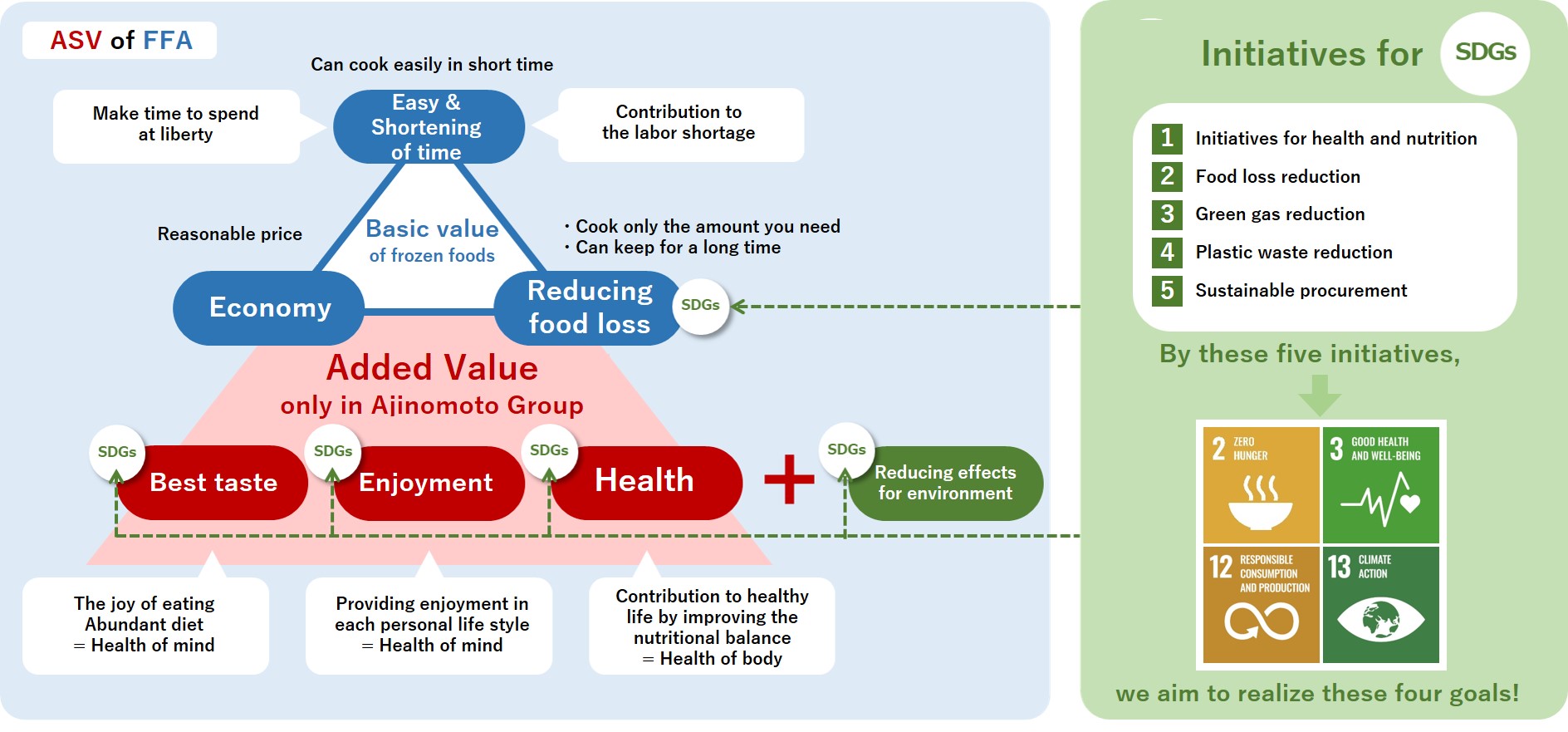

FFA's commitment and philosophy

FFA has been promoting company-wide efforts, including product development, to realize four added values unique to Ajinomoto Group: "No. 1 taste," "enjoyment," "health and nutrition," and "reduction of environmental impact," in addition to the three basic values of frozen foods: "convenience and short time," "economy," and "reduction of food loss," to help consumers enjoy healthy and affluent diets. In addition, Ajinomoto Group is promoting company-wide initiatives, including product development, to realize the four added values that only Ajinomoto Group can offer.

(From Ajinomoto Frozen Foods Co.)

-

- The No.1 taste

- Their goal is to create delicious products that will make people feel like they want to eat that product again at their daily meals.

-

- Enjoyment

- They continue developing and producing product that give people "fun" through cooking and making frozen foods such as the crispiness of the gyoza when cooked.

-

- Health and nutrition

- They develop products that support the healthy and enriched eating habits of consumers, such as food allergy-friendly products, low-sodium products that cut salt while maintaining the same delicious taste, products with universal design food standards that consider softness and nutritional value for hospitals and nursing homes, and products for vegetarians.

-

- Reducing environmental impact

- To contribute to the realization of a sustainable society, FFA strives for continuous improvement of corporate activities in harmony with the global environment and takes initiatives such as "reduction of greenhouse gases," "reduction of plastics," "reduction of food loss," and "sustainable procurement.

FFA has been working to solve social issues through its business, and has been improving its economic value by co-creating value together with society and the community, leading to growth. We call this series of initiatives "ASV (Ajinomoto Group Shared Value)”.

About Packaging of Products

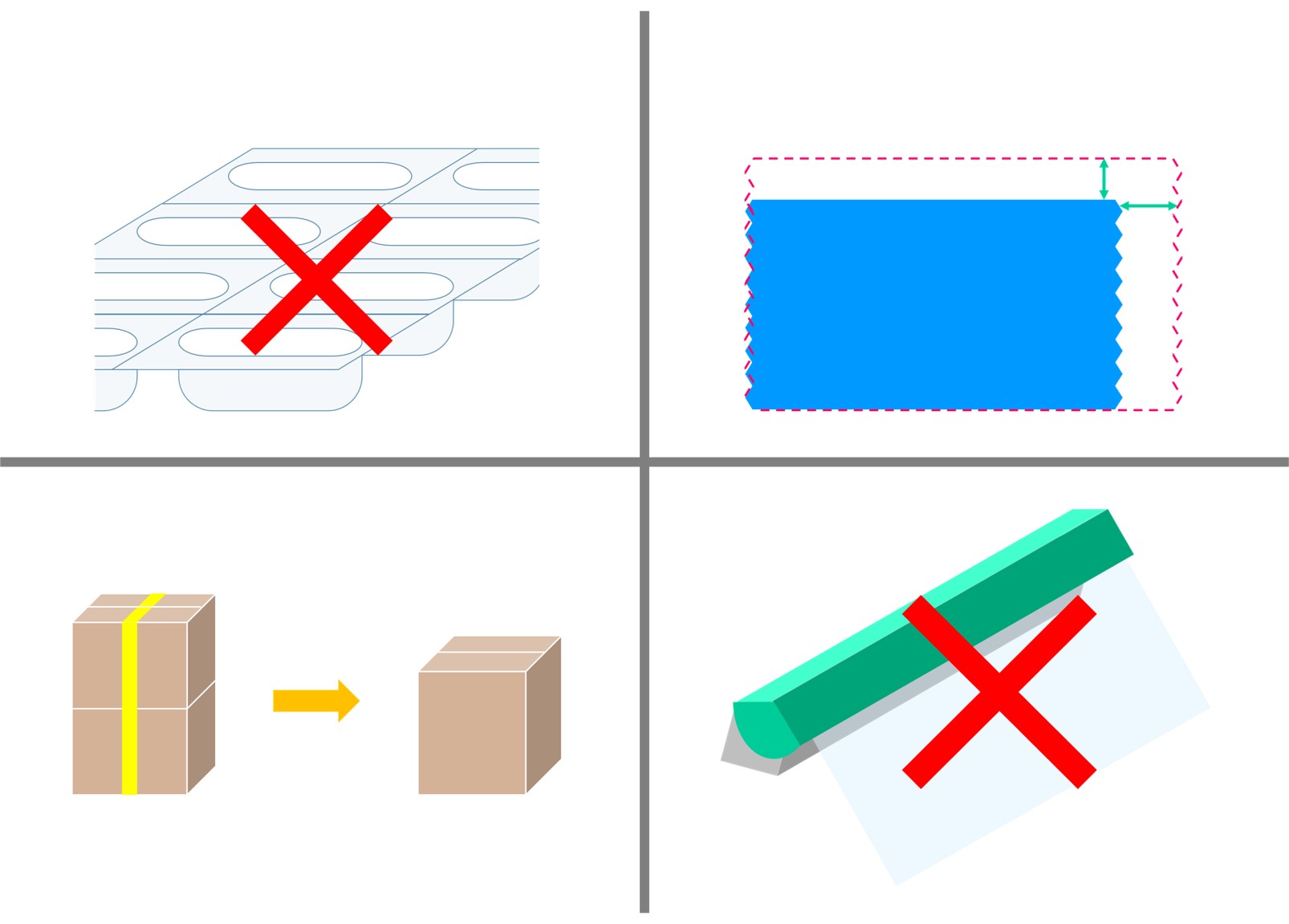

FFA is taking various steps to address the problem of waste plastic.

-

- Efforts to reduce plastic by not using trays

- By eliminating the use of trays for "Minna Waiwai Gyoza" and "32 Gyoza eco-pouches", they shave reduced the amount of plastic used by 11 tons per year.

-

- Resource Conservation by Reviewing Package Size

- By reducing the size of product packaging and the thickness of bags, they have reduced the amount of plastic used by 28.2 tons per year.

-

- Reduction in the use of PP bands during product shipment

- PP bands are the plastic bands used to bind cardboard. They have reduced the amount of PP bands used and reduced the amount of plastic used by 13.6 tons per year by using a single box instead of two boxes when shipping products.

-

- Development of products that can be cooked without plastic wrap

- To reduce the amount of waste not only during the manufacturing process but also when cooking at home, products that can be cooked without plastic wrap are being developed.。

About the Ingredients

There are many popular FFA products such as "Gyoza", "The★®" series, and "Ebi Shumai", but here I would like to introduce "Gyoza".

The term "Gyoza" does not just refer to the usual baked dumplings and water dumplings! There are a variety of products on the market, including allergy-friendly "Gyoza made with rice flour," "microwavable baked Gyoza," and "Gyoza for ginger lovers".

The wheat that is used to make the skin for these gyoza (except for "dumplings made of rice flour") is imported from Australia. So what happens when the price of wheat imports skyrockets, or when it becomes difficult to obtain wheat?

Flour is an important raw material that has a great impact on the quality of Gyoza. It is said that it is difficult to rely on wheat other than Australian wheat, because changing the place of production or other factors can greatly change the quality of the product.

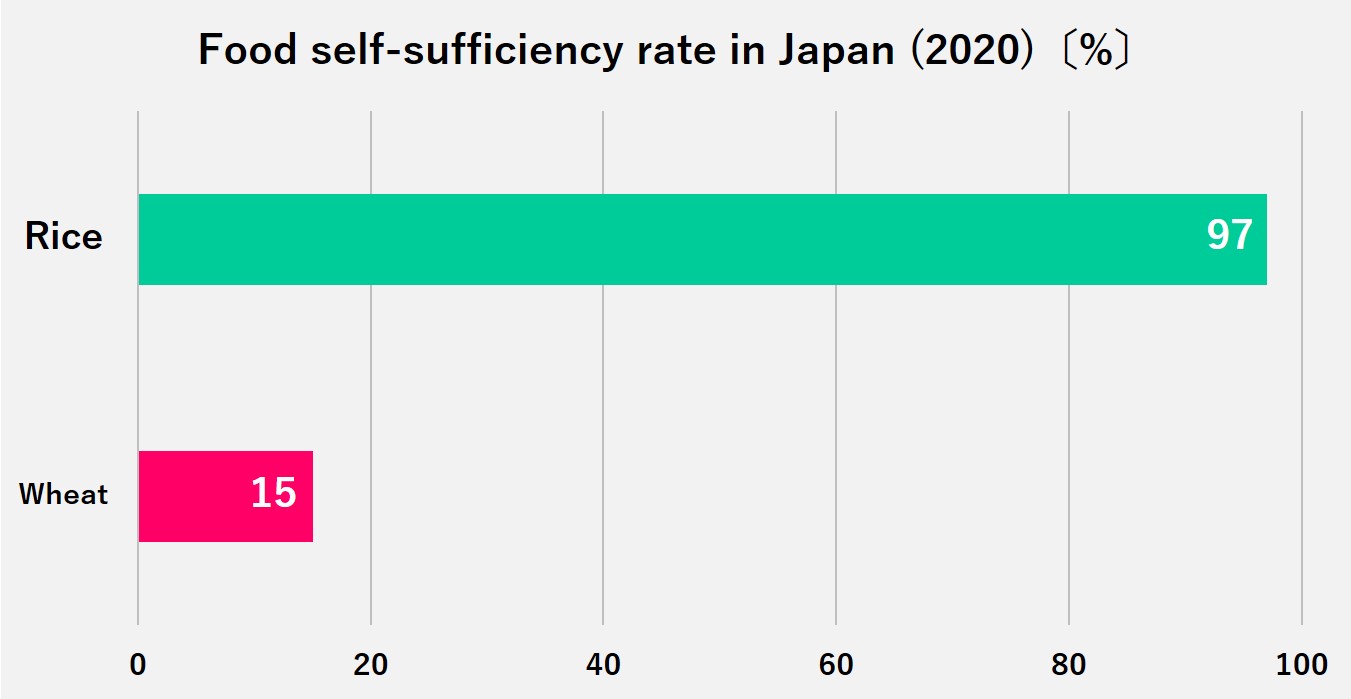

The same is true for wheat in Japan. Japan's warm and humid climate makes it unsuitable for wheat production, and rice cultivation is thriving instead. As you can see from the graph, the self-sufficiency rate of rice in Japan is 97%, while the self-sufficiency rate of wheat is only 15%.

In addition, since frozen foods are consumed daily, they continue to make efforts to avoid passing on the cost of frozen foods to the product price as much as possible.

About Distribution

At FFA, product storage and distribution are outsourced to companies in Ajinomoto Group. Since a cold chain of -18 degrees Celsius is important for frozen foods, temperature control is managed to ensure that the products are provided to consumers. In addition, they are promoting a modal shift from truck transportation to rail/marine transportation to reduce the environmental impact, and are also promoting joint delivery with other frozen food manufacturers for local delivery.

Efforts to Reduce Food Loss

FFA is implementing the following two initiatives to reduce food loss.

-

- Reducing food loss during production

- FFA is promoting the reduction of waste by reviewing the excessive removal of vegetable cores, etc., and reducing defective products and out-of-spec products during production. Food residues and other waste generated at factories are turned into compost and fertilizer, which are used for resource recycling. In FY2020, the domestic factories achieved a resource recycling rate of about 99%.

-

- Reduction of food loss after production (extension of shelf life)

- FFA is working on extending the shelf life of the products while confirming that there are no problems in terms of quality and safety using its strict standards.

FFA Image Character

"Ajipen®"

(From Ajinomoto Frozen Foods CO.)

We would like to deliver "excitement" and "joy" to everyone through frozen foods, so please keep your eyes on us. From the interviewee