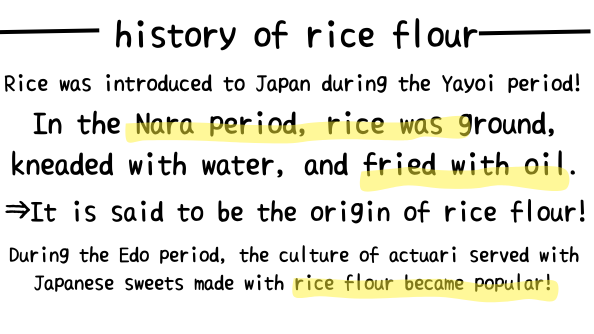

Manufacturing rice flour

1. Types of rice flour

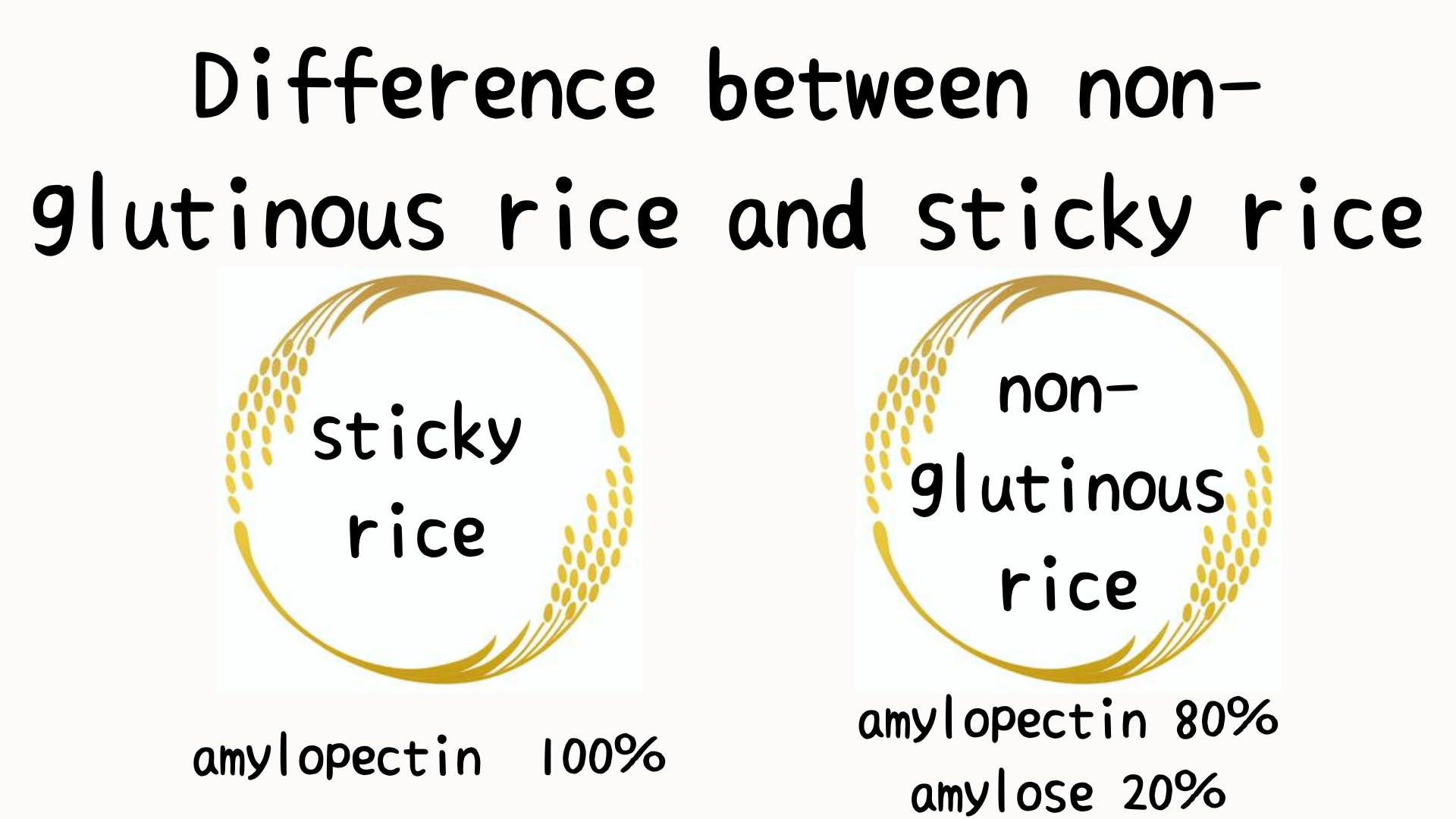

Raw materials for rice Types of rice

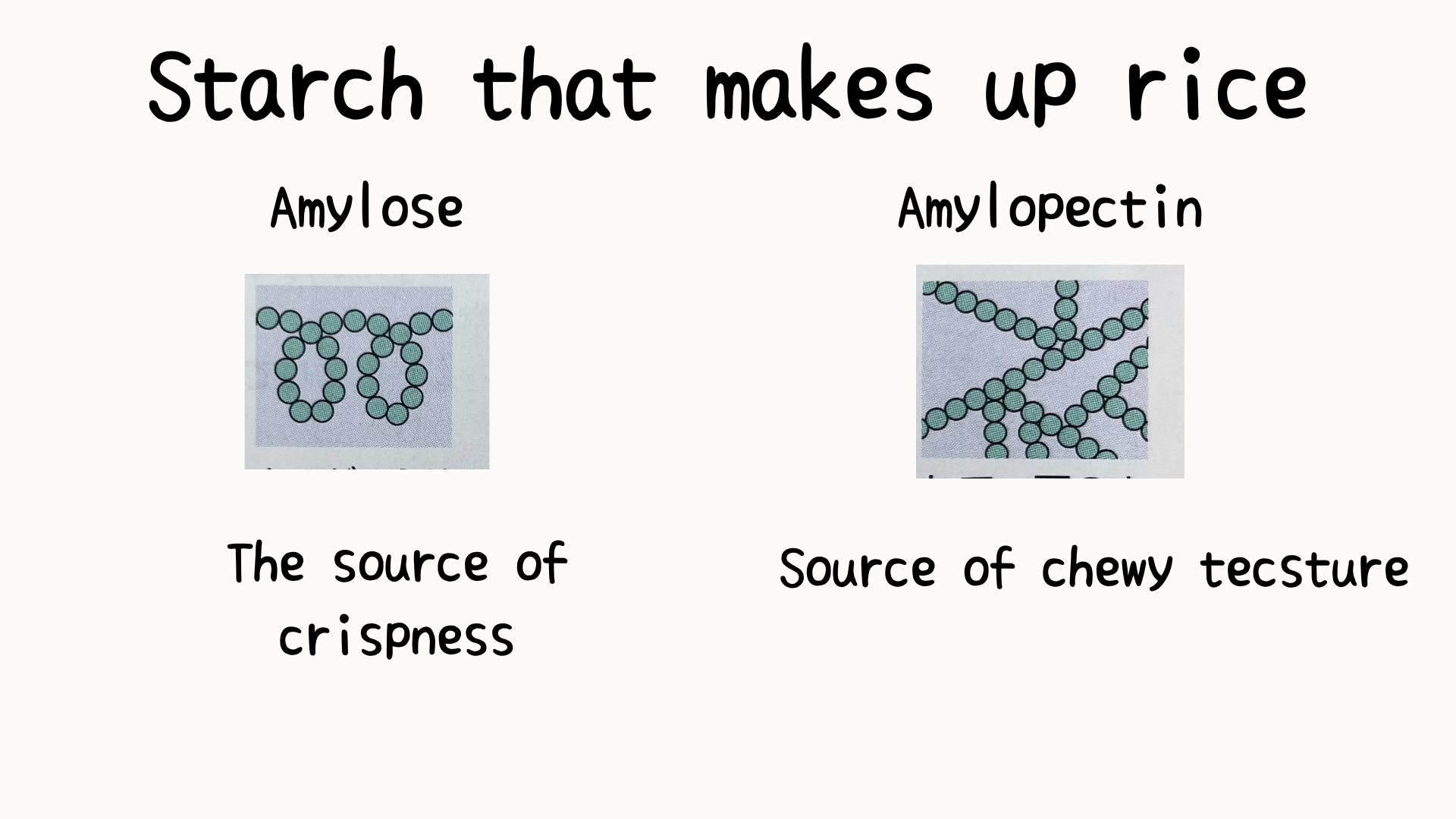

Types of starch that make up rice

[Classification of rice flour]

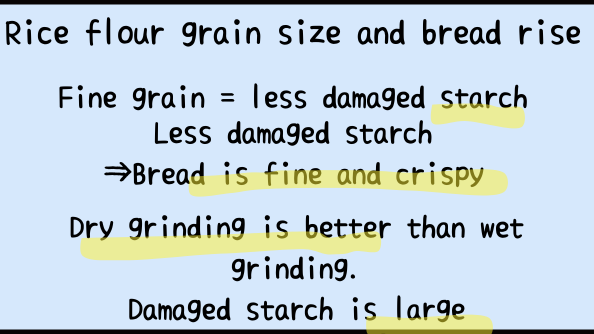

processing before crussing

non-glutinous rice

sticky rice

non-glutinous×sticky rice

※βization

dry and powderd

Wet milling

Joshinko

Jyoyokosticky rice

dango flour

chewy dumplings

dry and powderd

water griding methods

Shiratama flour

αization

mijin powder

namihaya powder

jyohaya powder

jyonan pwder

domyo pawder

rakugan powder

nyuji powder

1:For sweets and cooking (soft flour)

1:For sweets and cooking (soft flour) 2:For bread (strong flour)

2:For bread (strong flour) 3:For noodles (hard flour)

3:For noodles (hard flour)