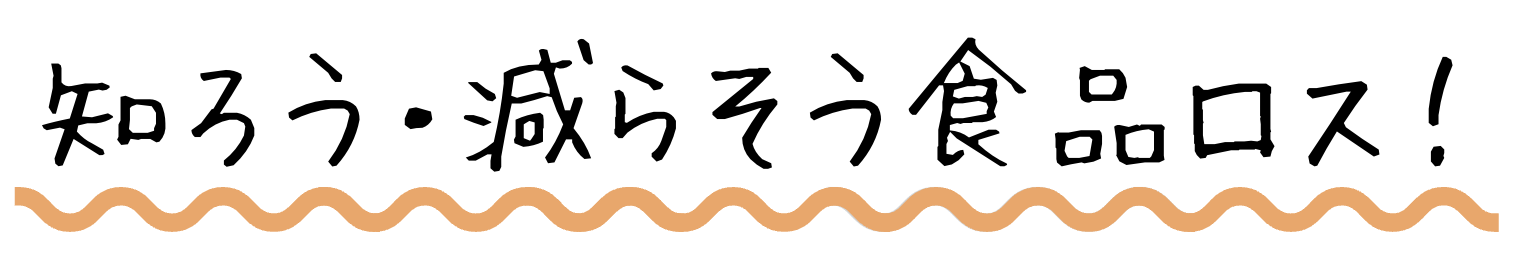

There are three stages in which business-related food loss occurs.

The manufacturing stage, the wholesale/retail stage, and the restaurant industry.

1. Manufacturing stage

(I) Strict quality standards

In factories where food is manufactured, products may crack or chip during the manufacturing process, and packages may be damaged.

If it does not meet the standards of the market, it is disposed of even if it is edible.

For example, non-standard products.

Non-standard products are products that do not meet the "standards" of

size, shape, quality, and color determined by the market.

If the product does not meet the specified weight or volume, or if the package looks different,

it is a product that cannot be distributed, and it will be subject to disposal.

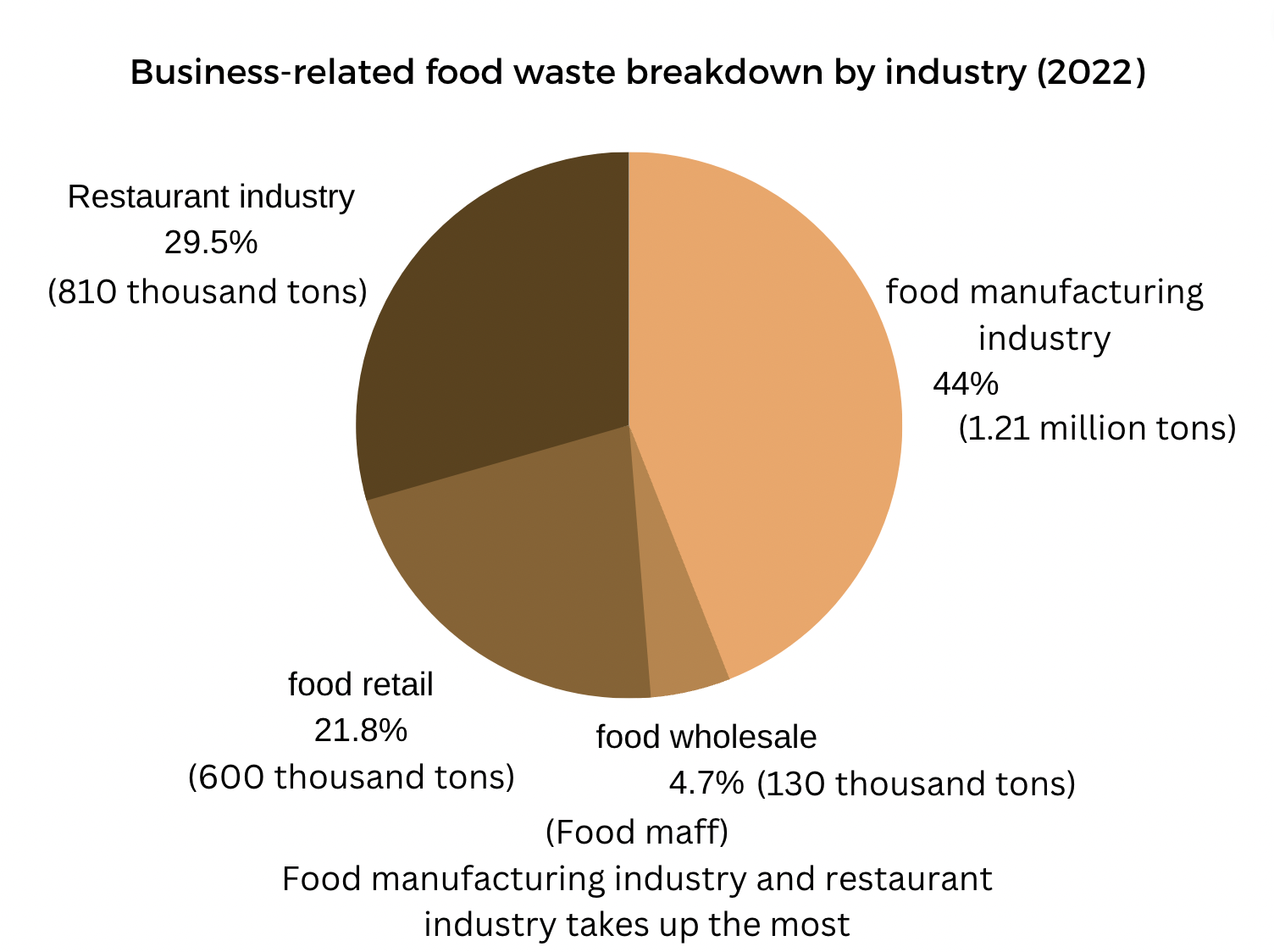

- What are non-standard vegetables? -

Non-standard vegetables are vegetables that do not meet the "standards" of size, shape, quality, and color determined by the market.

Sizes are classified as S, M, and L, and shapes, quality, and colors are classified as A, B, and C.

Vegetables that do not meet the standards and vegetables that are damaged and of poor quality are non-standard vegetables,

and these non-standard vegetables will not be shipped as products.

Some products become cut vegetables and processed products, but most of them are usually discarded.

The amount of vegetables that are discarded as non-standard vegetables is about 30% to 40% of the amount of vegetables produced.

You can eat it without any problems in terms of safety and sanitation,

but it doesn't sell just because it doesn't meet the standards...

It's very "mottainai",

But this is the result of producers trying to meet the high quality standards demanded by Japanese consumers.

Also, in the food industry, there is a custom of "stockout penalty".

If the manufacturer cannot meet the order volume of the retailer and runs out of the product,

the retailer, who emphasizes the loss of opportunity and the decrease in customer satisfaction due to being out of stock, may suffer.

You will be told to "suspend transactions" from the supplier,

or you will have to pay a fine to the ordering party.

To avoid this, manufacturers overproduce food so that there are no shortages.

As a result, more food is produced than the amount ordered, and the surplus food is disposed of.

(II) Planned mass production

Another factor that causes a large amount of food loss at the manufacturing stage is mass production by the manufacturing side.

In 2019, there was a lot of talk about the “Ehomaki problem,” in which unsold Ehomaki rolls were thrown away after Setsubun.

The production of these Ehomaki falls short of demand every year, and they are thrown away in large quantities.

One of the reasons for this is Japan's economic system of mass production and mass consumption.

Until now, the Japanese economy has been built on a cycle of mass production and mass consumption.

In a capitalist economy, the way companies make profits is by producing goods and selling those goods.

In other words, you can maximize your profit by producing as many goods as possible and selling as many of these goods as possible.

In the case of the ehomaki problem given as an example earlier,

it is not possible to perfectly predict the right amount of ehomaki that will not be in short supply.

Therefore, the company compares the cost of disposal with the expected loss if the shortage sale does not increase.

In many cases, it is more profitable to produce and

dispose of a large amount of food than not to produce it, resulting in a large amount of food waste.

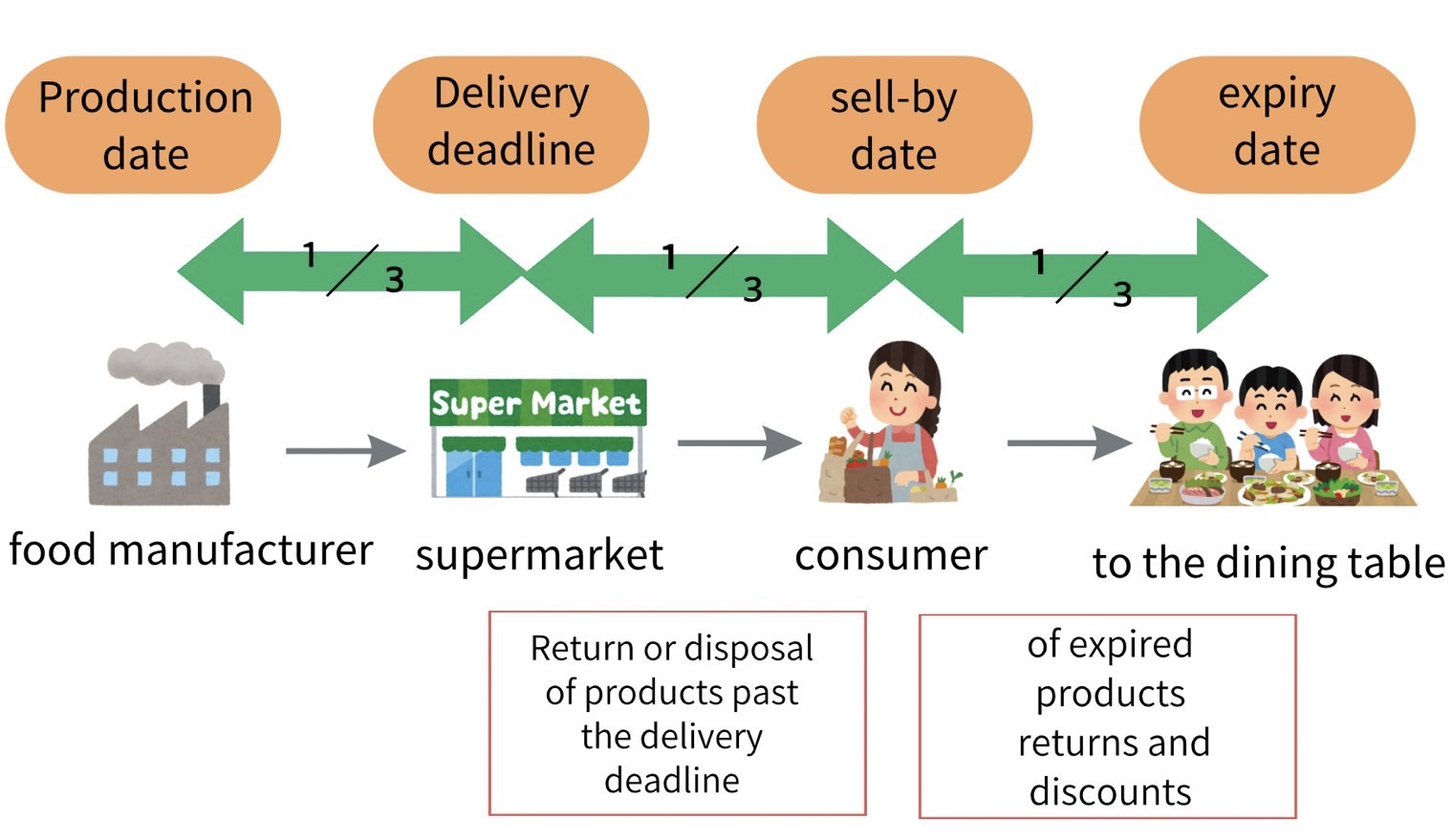

2. Wholesale/retail stage

At the stage where food products are sold by wholesalers and retailers,

delivery deadlines and sell-by deadlines are set according to the custom of the food industry's "one-third rule."

This rule divides the period from the date of manufacture of the food to the expiration date of the food into three equal parts.

First period is the period during which the product must be delivered,

the next one-third period is the "sell-by date" (the period during which the retailer may keep the product on the shelf),

the last one-third period is defined as the "best before date" (the period during which consumers can enjoy the food).

Other countries also have delivery deadlines for food,

but Japanese consumers tend to be particularly demanding about the quality and appearance of food.

Due to this one-third-rule, the distribution of food is restricted, and the value of food has greatly decreased just past "one-third".

For example, products that cannot be delivered to retailers two months before the expiration date will be returned to the food manufacturer.

The returned food cannot be sold at the normal price, and about 20% of it can be collected by discount stores, etc.

The rest of the food will be discarded.

In the supply chain, there is a custom to display products with a guaranteed expiration date on the shelves,

but this has lead to a large amount of food loss.

In the background of business food loss, there were unspoken rules in the industry

such as the "shortage penalty" and the "one-third rule".

You can see the idea of "consumer supremacy" that wants to meet the demands of consumers

who expect a wide variety of products as new as possible.

Food waste in convenience stores

Convenience stores are spread all over Japan, and the number of stores is very large.

It is a problem that a lot of food waste

occurs due to the disposal of foods such as bento boxes and rice balls that have expired at each store.

There are more than 50,000 convenience stores in Japan, but currently, about 50 to 70 kg of waste is disposed of on average per store per day.

One-fifth of it is food waste, weighing about 10 to 15 kg.

Convenience stores in Japan are at a very high quality, as they have refined every service to satisfy their customers.

Almost the same products are sold in both cities and rural areas, and many stores are open 24 hours a day.

However, the results of these companies' efforts have created a structure that makes it easy for food waste to occur.

In order to reduce waste, it is necessary to build a new sense of value that will increase user satisfaction,

rather than instant gratification.

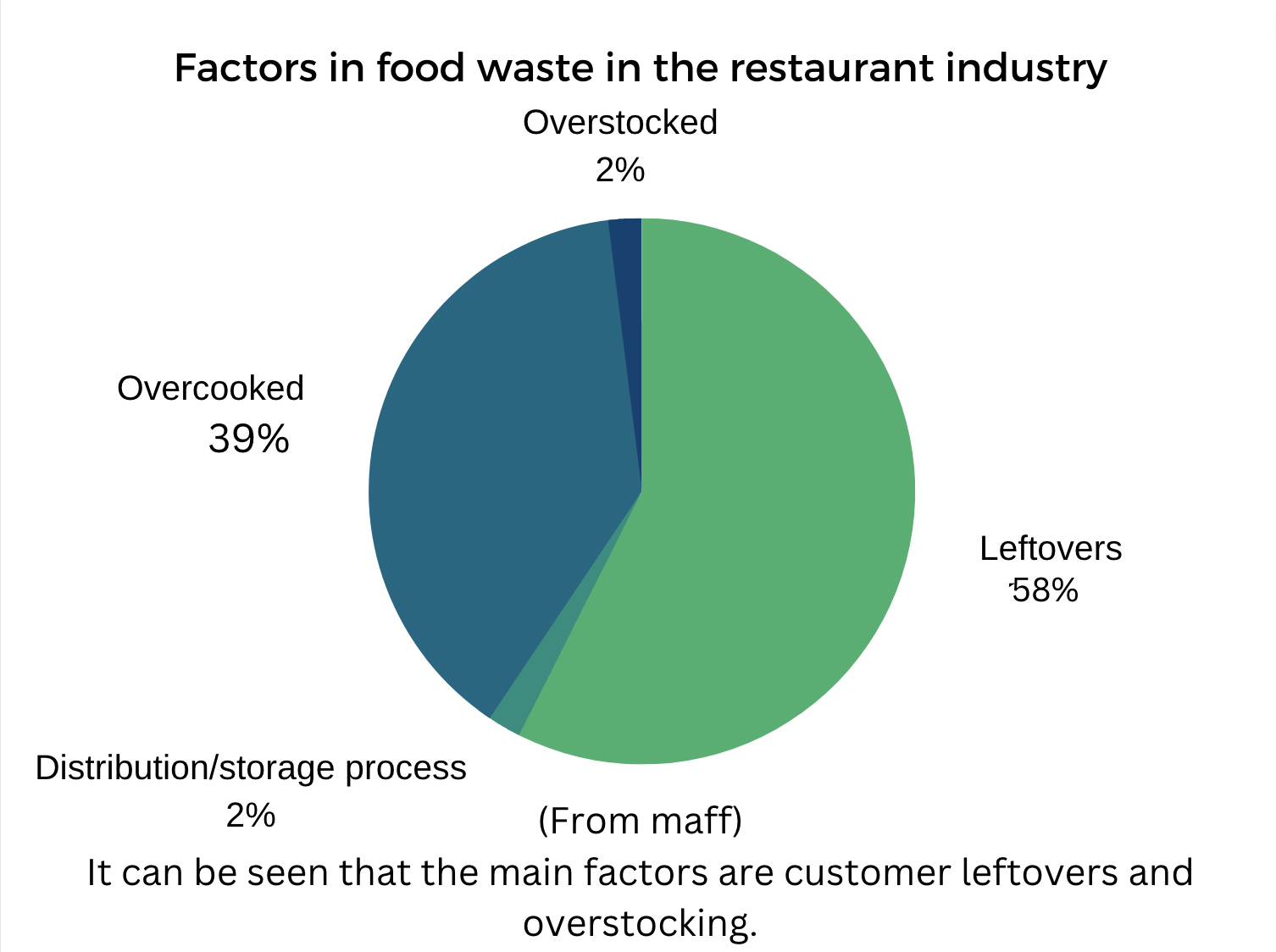

3. Restaurant industry

In the restaurant industry, a large amount of food is disposed of every day.

As for the cause of the store side, when manufacturing and cooking food,

it is prepared in advance by referring to past sales and events at nearby facilities.

Production is often higher than consumption.

In addition, in order to respond to a variety of menus because

they do not want to miss business opportunities,

they prepare excessively in advance, which may lead to food waste.

Restaurants do not lose money as long as the customer places an order and pays the price,

and there are times, when they provide more than they can eat as part of their excessive service.

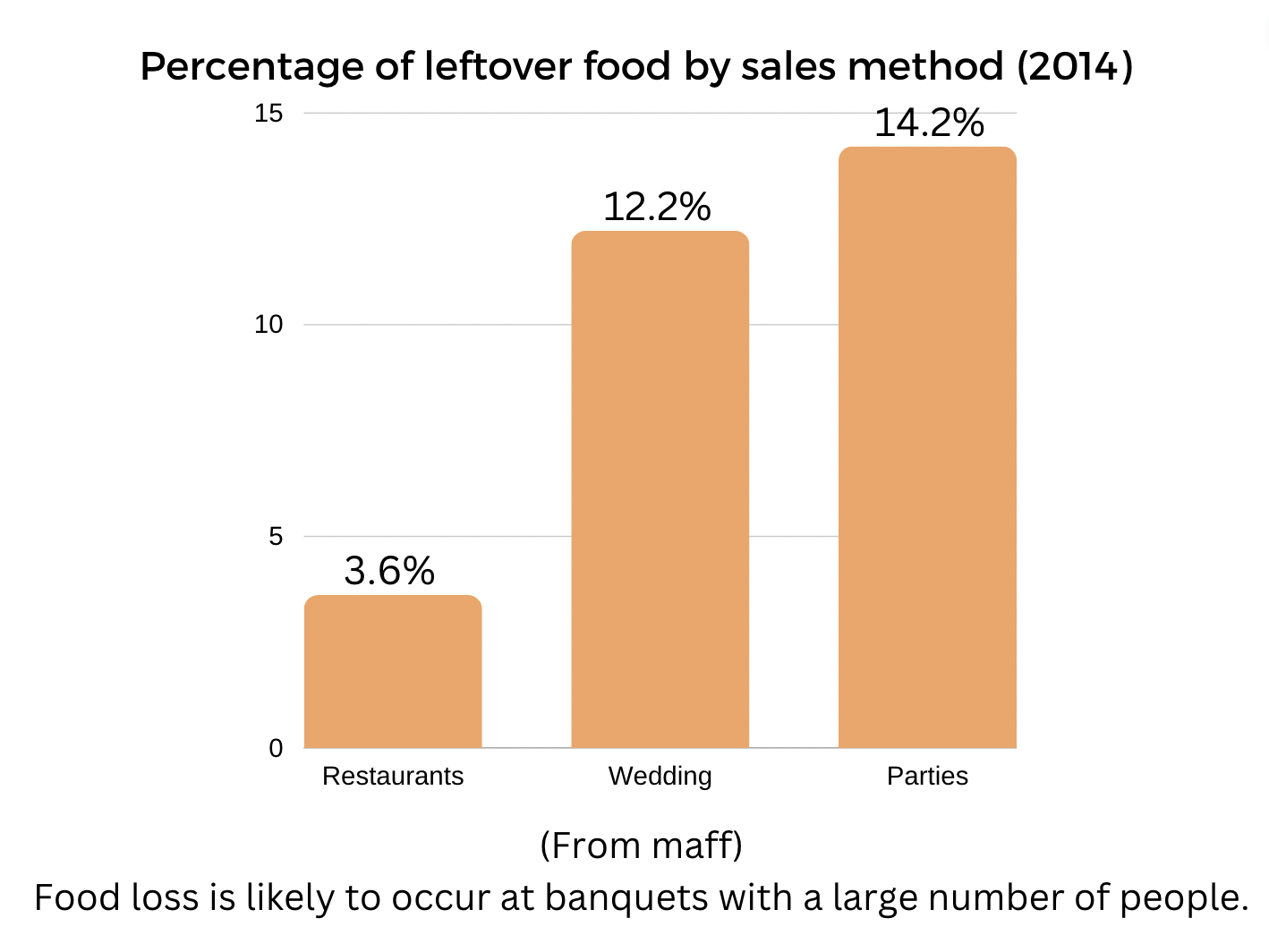

On the customer side, the main cause ordering without knowing the amount and ending up leaving the food behind.

In addition to this, customers sometimes order food just to post photos of it on SNS to collect likes.

Also, an abundance of food brightens up parties, so people might over buy.

Bibliography :

・株式会社エクシール -『食品ロスの原因「規格外野菜」|購入するメリットと販売場所3選の紹介!』

(https://www.exseal.co.jp/blog/taxonomy-27/9821/)

・全国農業協同組合連合会 広島県本部 -「出荷規格表」

(https://www.zennoh.or.jp/hr/syukkakikaku/)

・農林水産省 -「食品ロス及びリサイクルをめぐる情勢」(https://www.maff.go.jp/j/shokusan/recycle/syoku_loss/attach/pdf/161227_4-52.pdf)

・「⾷品ロス量の推移」(https://www.maff.go.jp/j/press/shokuhin/recycle/attach/pdf/220609-5.pdf)

「外食・中食産業における食品ロスについて」(https://www.maff.go.jp/j/shokusan/recycle/syoku_loss/170516.html)

・kuradashi -「恵方巻きの廃棄問題とは?フードロス対策の4つの事例を紹介」(https://kuradashi.jp/blogs/kuradashi-magazine/455)

・Yahoo News -「食品ロスを生み出す「欠品ペナルティ」は必要? 商売の原点を大切にするスーパーの事例」(https://news.yahoo.co.jp/byline/iderumi/20170806-00073974)

(食品ロス問題ジャーナリスト・栄養学博士、井出留美さんの記事)

・japan-eat’s blog -「食品ロスとは Fin」(流通ジャーナリスト、渡辺広明さんによる記事)(https://japan-eat.com/entry/2022/02/24/113036)