Housing

Table of Contents

Provided by Serendix

▲3D Printed House “Sphere"

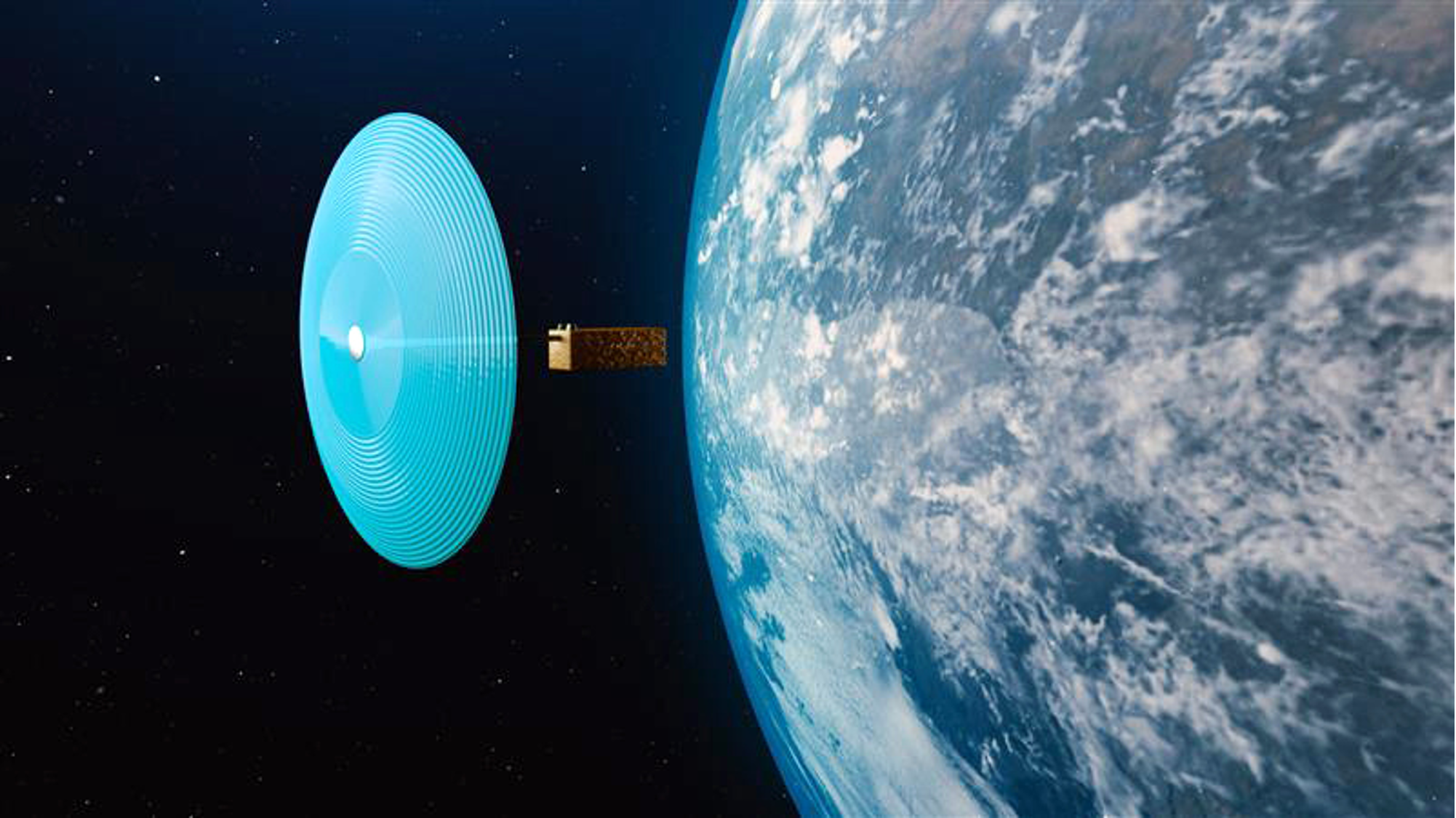

Provided by CLOUDS Architecture Office

▲3D Printed House “Sphere"

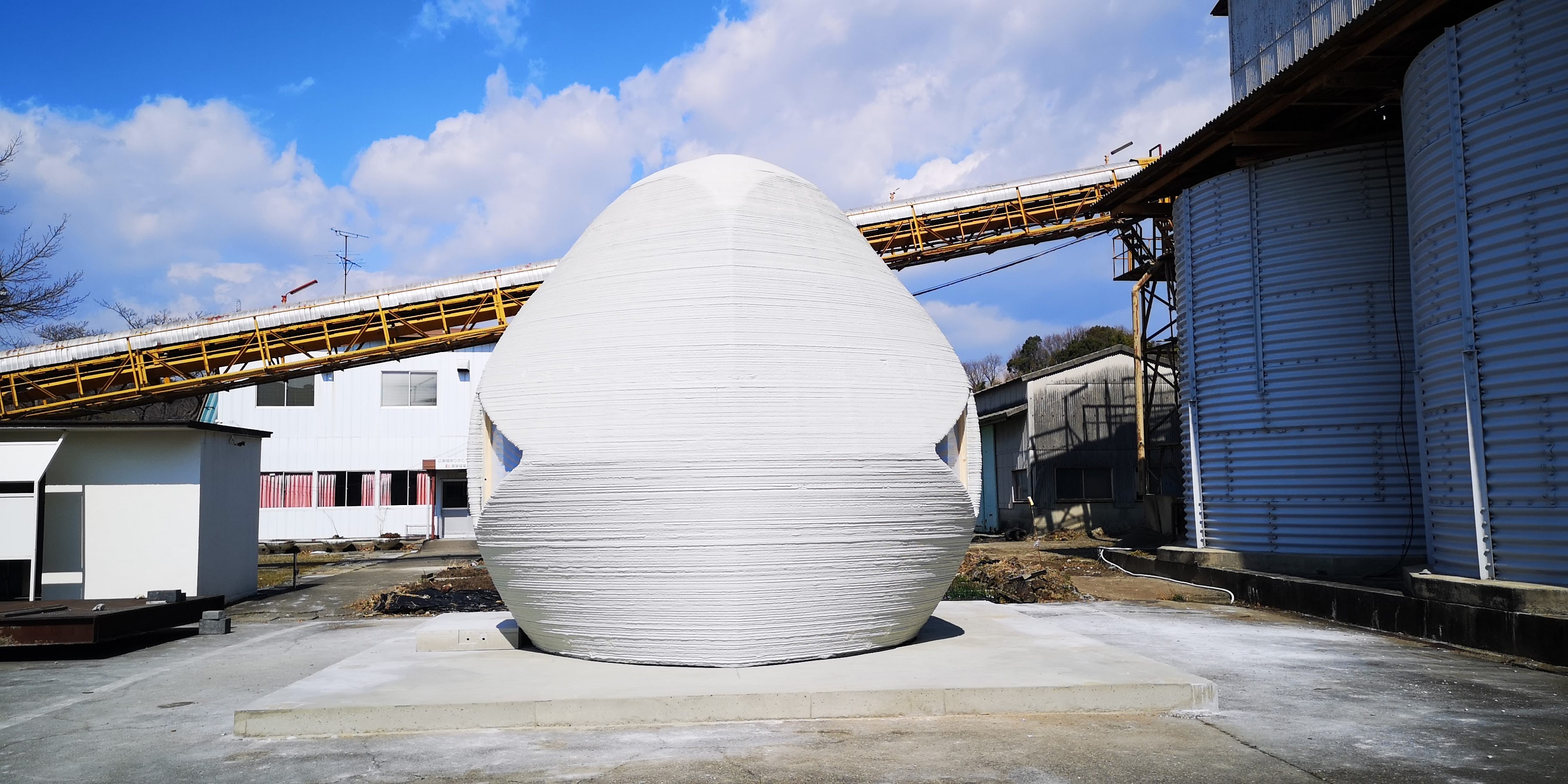

Provided by Emu Masuyama, Digital Manufacturing and Design Research Center for Emergent Circularity, Keio University

▲3D Printed House “FUJITSUBO Model"

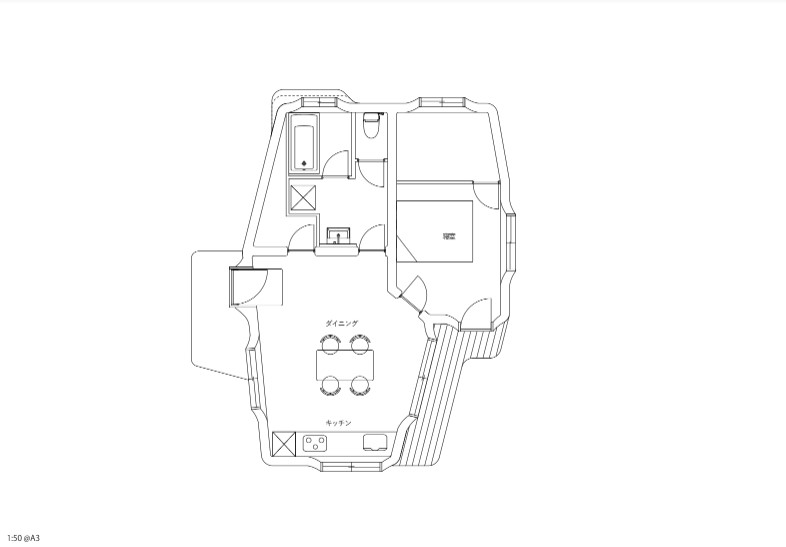

Provided by Emu Masuyama, Digital Manufacturing and Design Research Center for Emergent Circularity, Keio University

▲ Plan of「FUJITSUBO Model」

We interviewed Serendix online regarding its research on 3D Printer Housing on August 9th, 2022.

Place: Member's home

▲Appearance of Interview

We asked the following seven questions about "Housing x 3D Printer."

Q.1

What project are you working on?

A.1

We are inventing a new type of house, "Sphere," which we can build in 24 hours and provide it at 3 million yen.

▲This is the video showing how to make a Sphere. ; Provided by Serendix

This video shows an operable nozzle A nozzle is a component that extrudes filament (resin) and prints it on the stage. is used for adding layers and building a Sphere.

A nozzle is a component that extrudes filament (resin) and prints it on the stage. is used for adding layers and building a Sphere.

Q.2

Could you explain why you came to work on such a project?

A.2

Koma, CEO, and Handa, COO, discussed their new project, "Create the most advanced house in the world," and promoted the agenda. The idea is to provide our customers with a house they can purchase at a low price, like a car, and they don't have to take out a mortgage. As a result, they can live more easily.

Q.3

We heard that the Spherical type is a suitable shape for a Sphere. What problems would you face if you designed other types of shapes?

A.3

Sphere is physically strong because of its Spherical shape, as its walls support each other. Sphere is one piece of an object, because of which we can reduce labor costs and sell at 3 million yen.

Provided by Serendix

▲Sphere is being built.

Provided by Serendix

▲Completion photo of Sphere

Q.4

What are the strengths of Sphere?

A.4

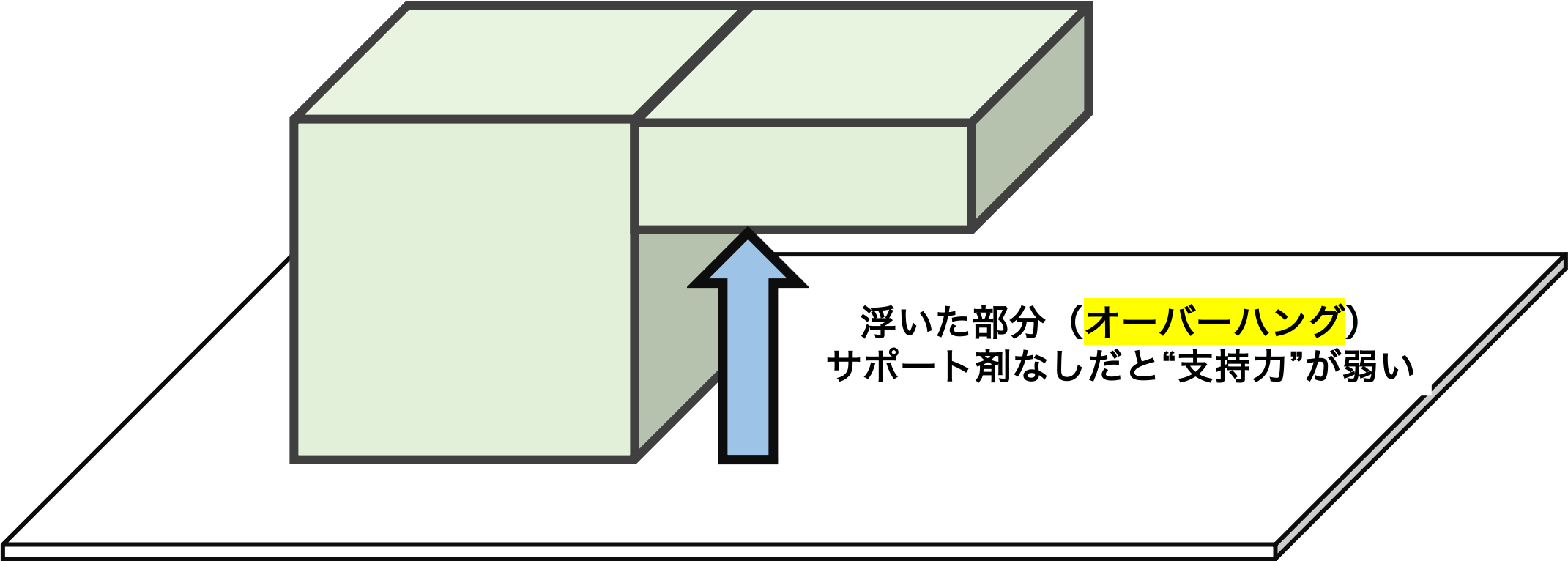

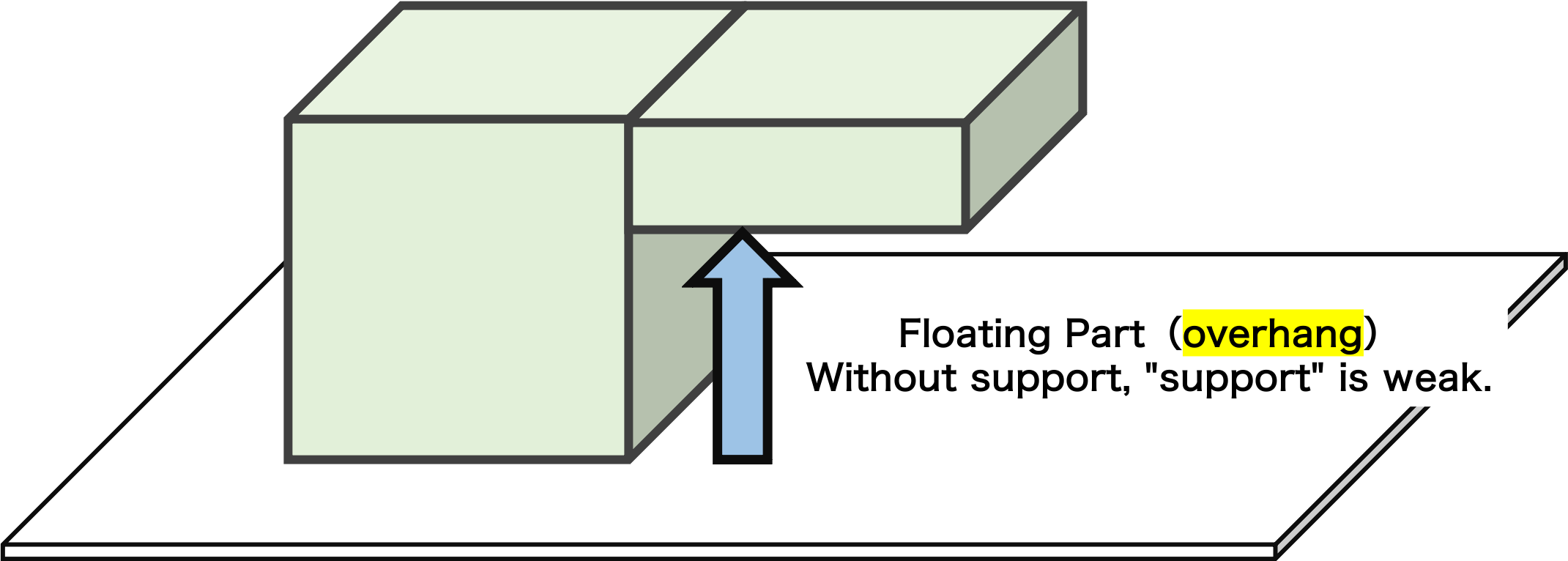

It's our mindset to try. The shape of houses made with 3D printers is generally rectangular. But we created a rounded-shaped home by making use of an overhang An overhangs is an area in a modeling object that is floating in the air without support. Support structures is required when printing moldings., which was the first trial in the world.

An overhangs is an area in a modeling object that is floating in the air without support. Support structures is required when printing moldings., which was the first trial in the world.

Made by us

Q.5

What problem are you having at the moment?

A.5

Umm…

Since there is a great possibility of falling the wall while building a house, it is very challenging to harden the material before falling. It is also challenging to adjust the angle of a printer's head so that the printer can successfully produce the target objects.

Q.6

What skills do you think will be required in the future?

A.6

When we started this project, we couldn't find any expert in creating 3D data on housing in Japan. However, there are some experts in this field in other countries, so it is necessary to obtain their knowledge. We plan to translate information written by them into Japanese so that we can acquire the skills required to create 3D data on housing.

Q.7

What do you envision as the ideal form?

A.7

It costs 20 million to 30 million yen to buy a new house.

However, a "Sphere" is about 3 million yen, almost the same price as a car. Some people can even buy it without relying on a mortgage. If we buy a Sphere, we are expected to take out a 5-year mortgage, and we can pay off the mortgage 25 years earlier than a 30-year mortgage.

As a result, our customers don't have to worry about their mortgages, enabling them to live more happily. This is our aim.