Stereolithography

Stereolithography is a method that draws each layer and stacks them by solidifying liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. with a UV laser. We’ll introduce the feature and printing process of Stereolithography on this page.

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. with a UV laser. We’ll introduce the feature and printing process of Stereolithography on this page.

Table of Contents

The table is the basic information list of Stereolithography.

| ISO standards | Vat Photo Polymerization |

|---|---|

| Aliases | SLA, DLP, LCD |

| Cost | Some are inexpensive |

| Performance | Good |

How can we print 3D objects with Stereolithography?

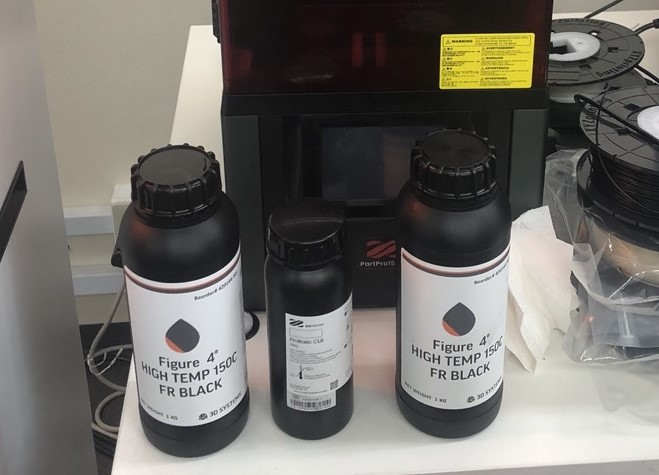

We set liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling.(UV resin), which was solidified by UV laser, in a tank.

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling.(UV resin), which was solidified by UV laser, in a tank.

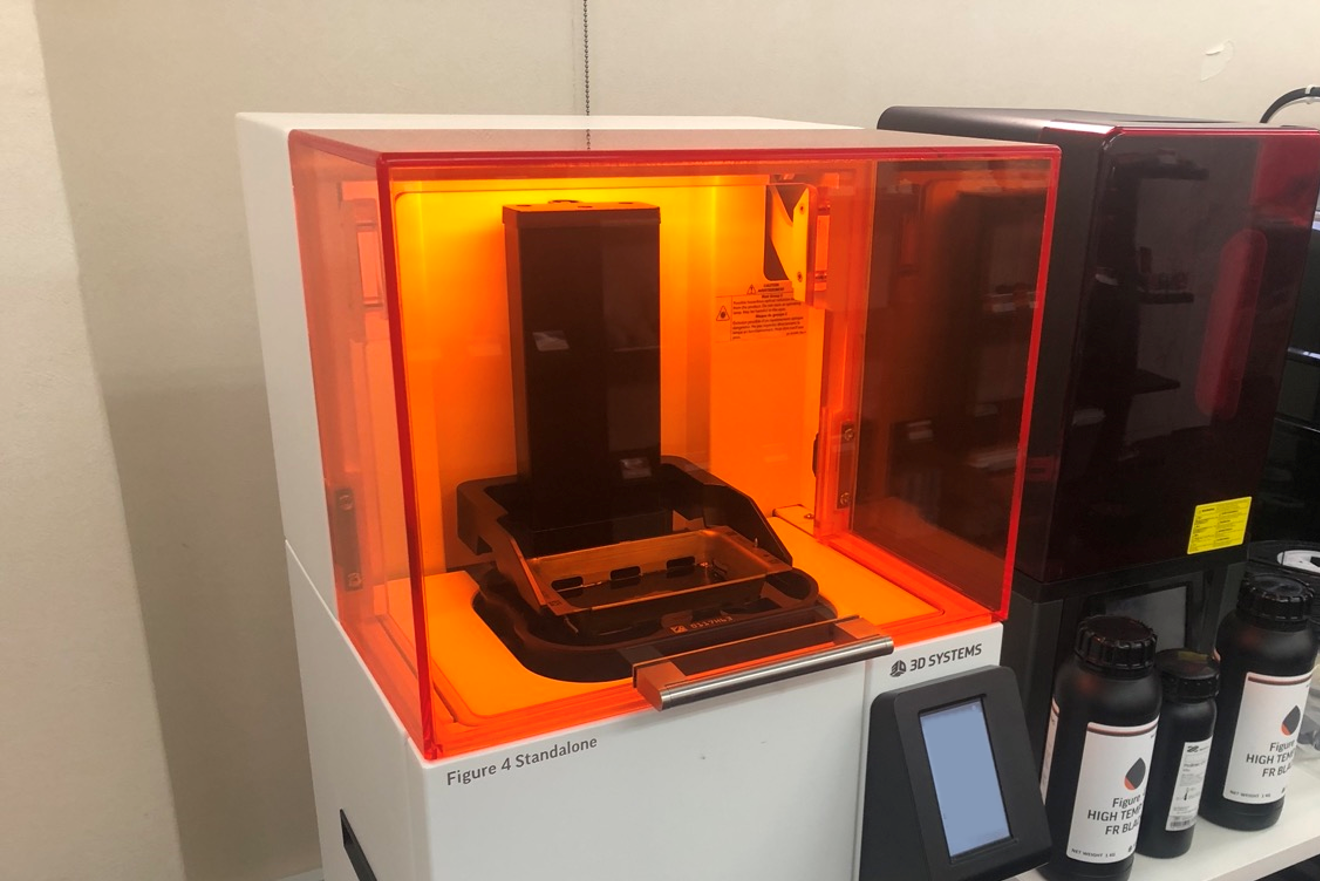

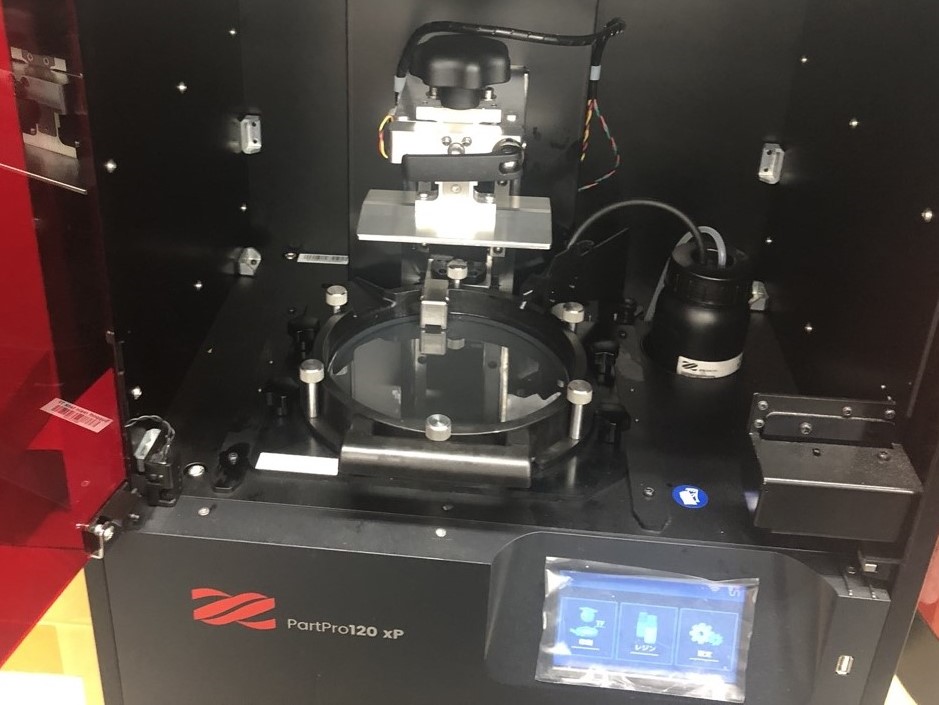

Place: 3D Solution Center

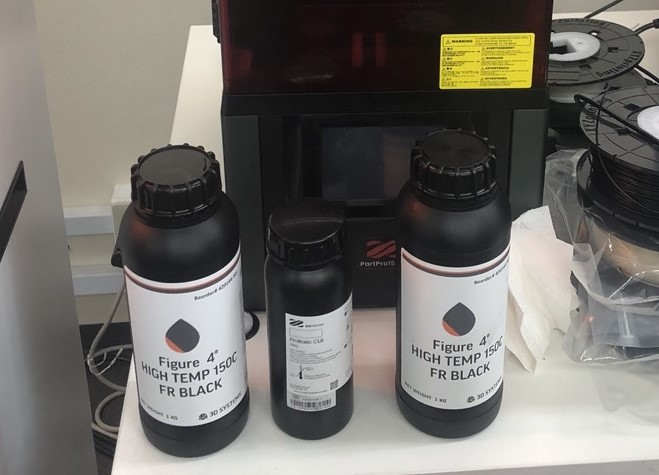

▲Picture of the case of liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling..

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling..

Solidify liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. with a UV laser and form a specified shape.

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. with a UV laser and form a specified shape.

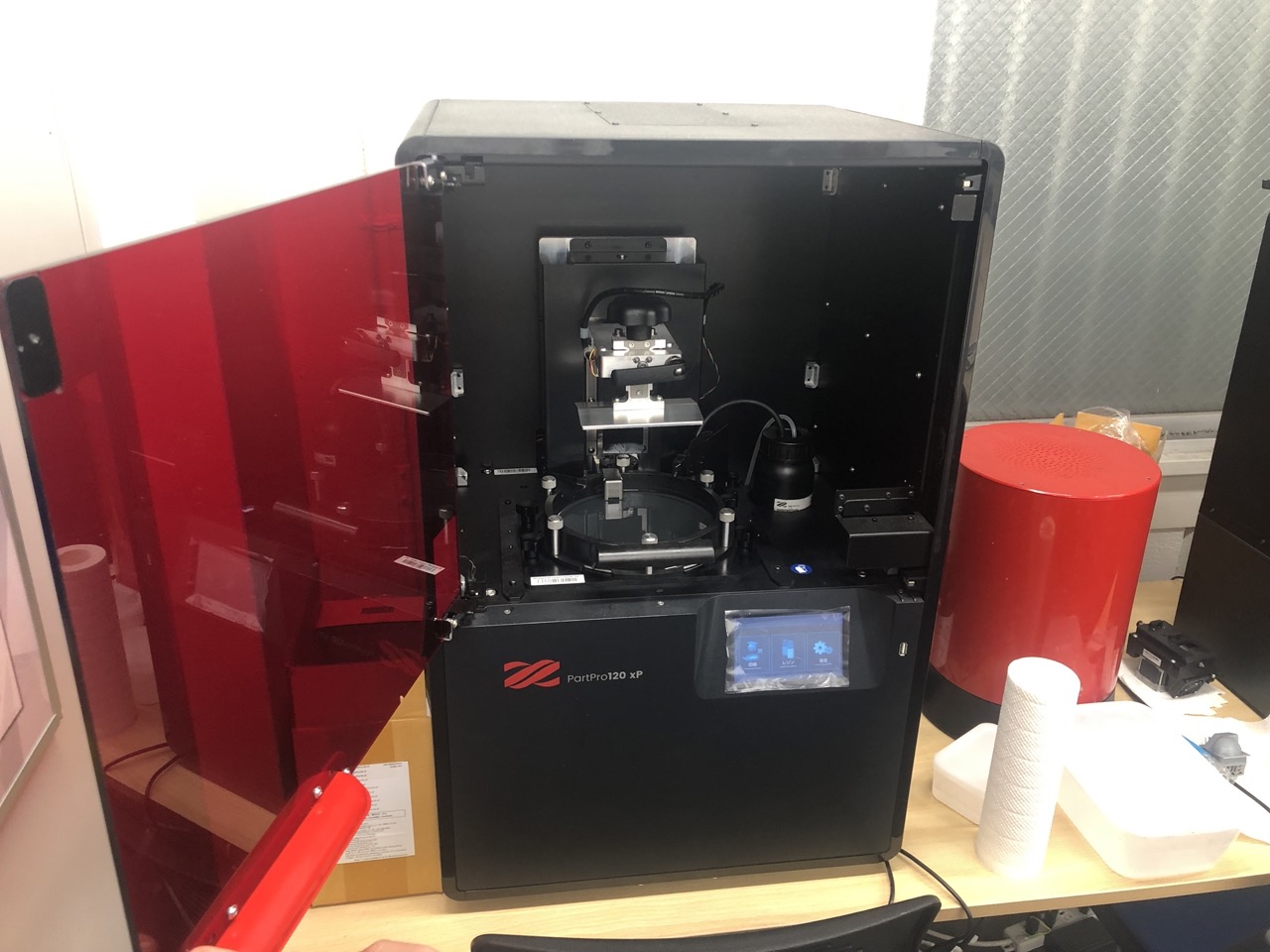

Place: 3D Solution Center

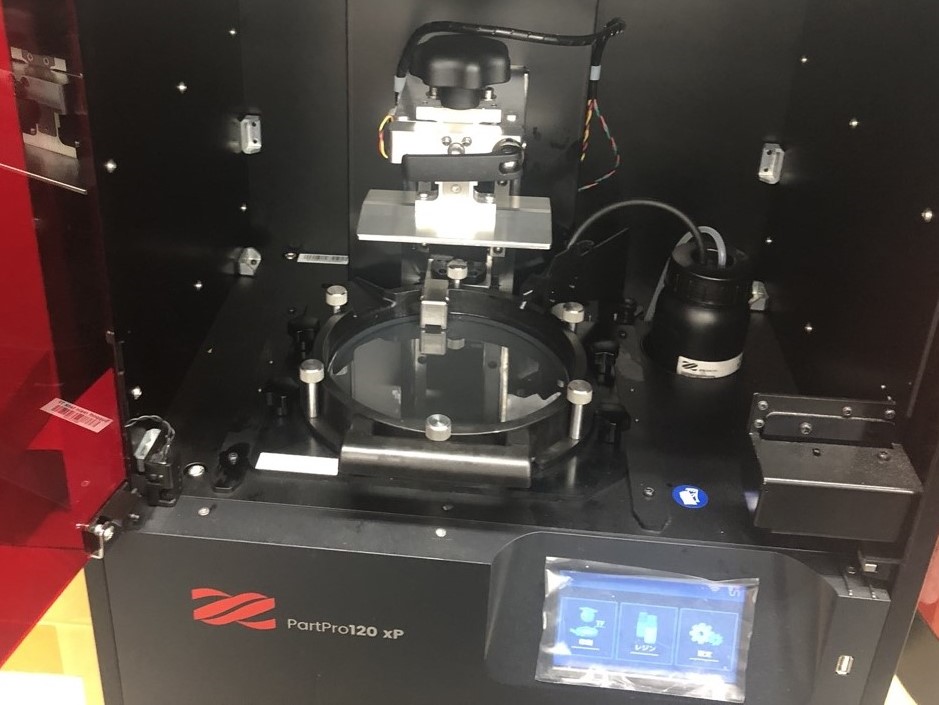

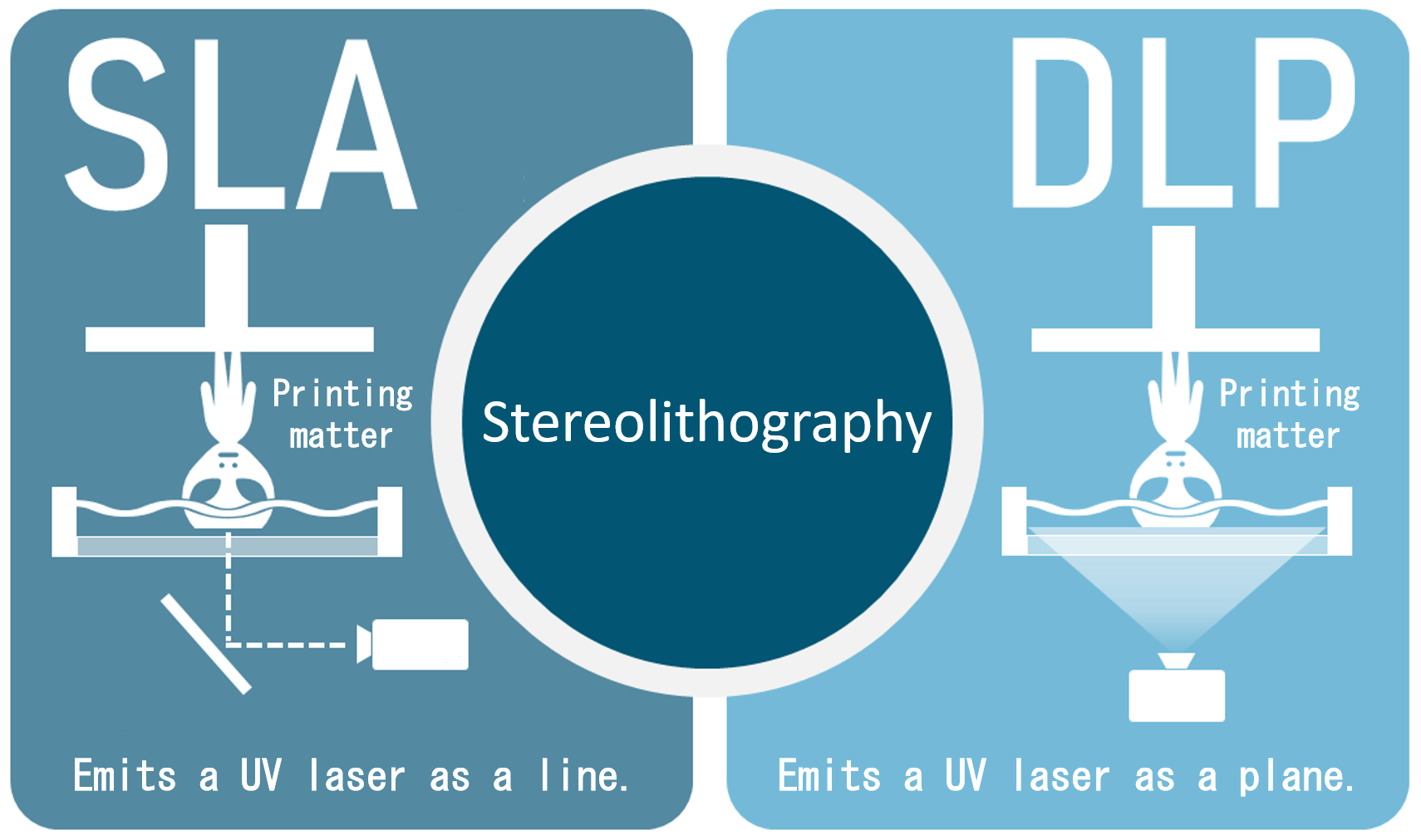

▲Structure of Stereolithography.

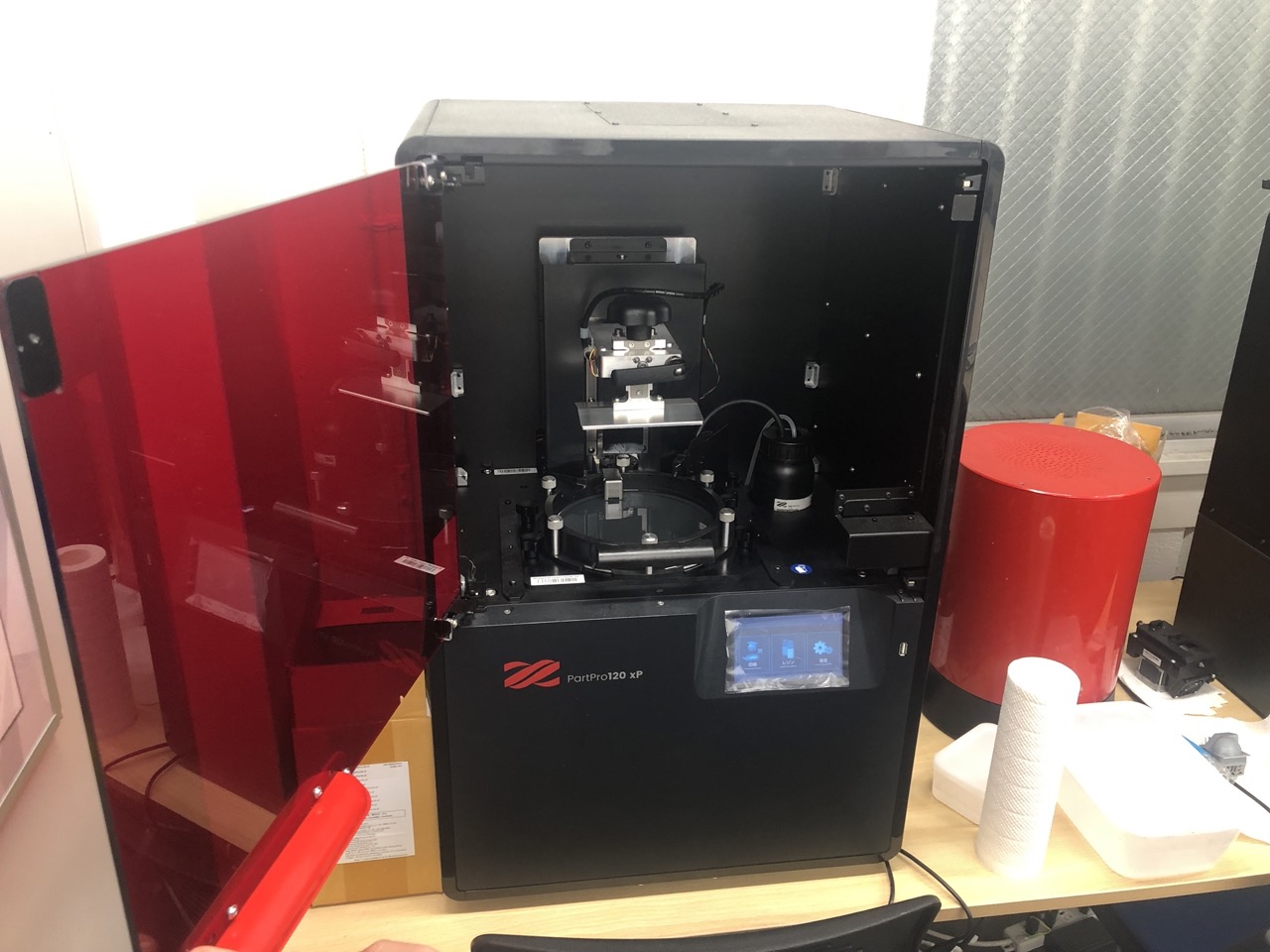

Place: 3D Solution Center

▲The picture is a tank that emits a UV laser from its bottom.

Especially, SLA SLA is the acronym for Stereolithography Apparatus and an alias of Stereolithography. Especially, SLA is a system that emits a linear UV laser and gradually prints a layer. is a system that emits a linear UV laser and gradually prints a layer. This system can create elaborate objects thanks to the laser.

SLA is the acronym for Stereolithography Apparatus and an alias of Stereolithography. Especially, SLA is a system that emits a linear UV laser and gradually prints a layer. is a system that emits a linear UV laser and gradually prints a layer. This system can create elaborate objects thanks to the laser.

DLP DLP is the acronym for Digital Light Processing and an alias of Stereolithography. Especially, DLP is a system that emits a UV laser in the form of a plane with a projector and prints a layer at once. and LCDLCD is the acronym for Liquid Crystal Display and an alias of Stereolithography. Especially, LCD is a system that emits a UV laser in the form of a plane with a liquid crystal display and prints a layer at once. are systems that emit a UV laser in the form of a plane and print a layer at once. The qualities of the objects made by DLP

DLP is the acronym for Digital Light Processing and an alias of Stereolithography. Especially, DLP is a system that emits a UV laser in the form of a plane with a projector and prints a layer at once. and LCDLCD is the acronym for Liquid Crystal Display and an alias of Stereolithography. Especially, LCD is a system that emits a UV laser in the form of a plane with a liquid crystal display and prints a layer at once. are systems that emit a UV laser in the form of a plane and print a layer at once. The qualities of the objects made by DLP DLP is the acronym for Digital Light Processing and an alias of Stereolithography. Especially, DLP is a system that emits a UV laser in the form of a plane with a projector and prints a layer at once. and LCDLCD is the acronym for Liquid Crystal Display and an alias of Stereolithography. Especially, LCD is a system that emits a UV laser in the form of a plane with a liquid crystal display and prints a layer at once. are slightly worse than those made by SLA

DLP is the acronym for Digital Light Processing and an alias of Stereolithography. Especially, DLP is a system that emits a UV laser in the form of a plane with a projector and prints a layer at once. and LCDLCD is the acronym for Liquid Crystal Display and an alias of Stereolithography. Especially, LCD is a system that emits a UV laser in the form of a plane with a liquid crystal display and prints a layer at once. are slightly worse than those made by SLA SLA is the acronym for Stereolithography Apparatus and an alias of Stereolithography. Especially, SLA is a system that emits a linear UV laser and gradually prints a layer., but the printing speed is fast, and the printers themselves are affordable.

SLA is the acronym for Stereolithography Apparatus and an alias of Stereolithography. Especially, SLA is a system that emits a linear UV laser and gradually prints a layer., but the printing speed is fast, and the printers themselves are affordable.

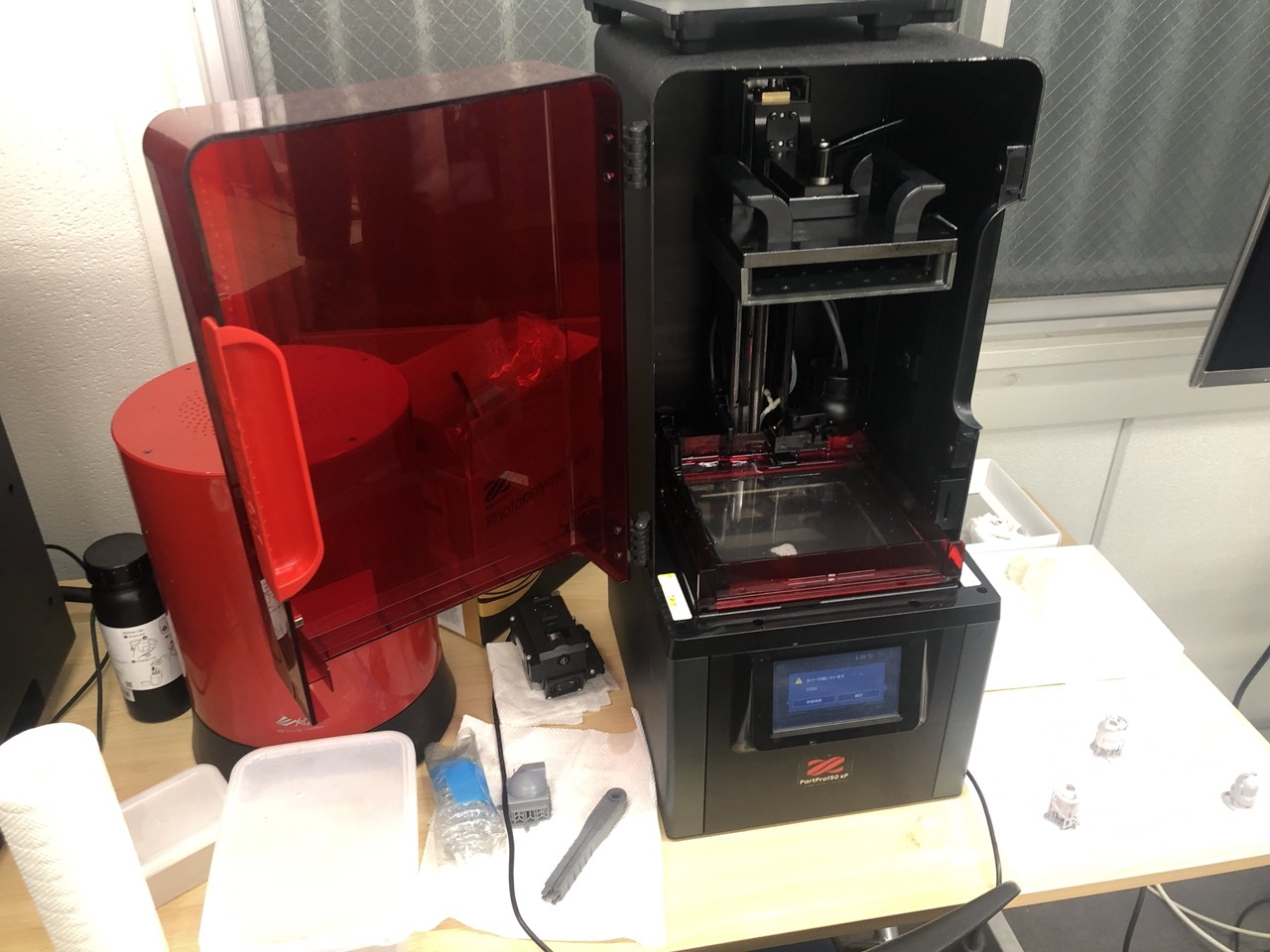

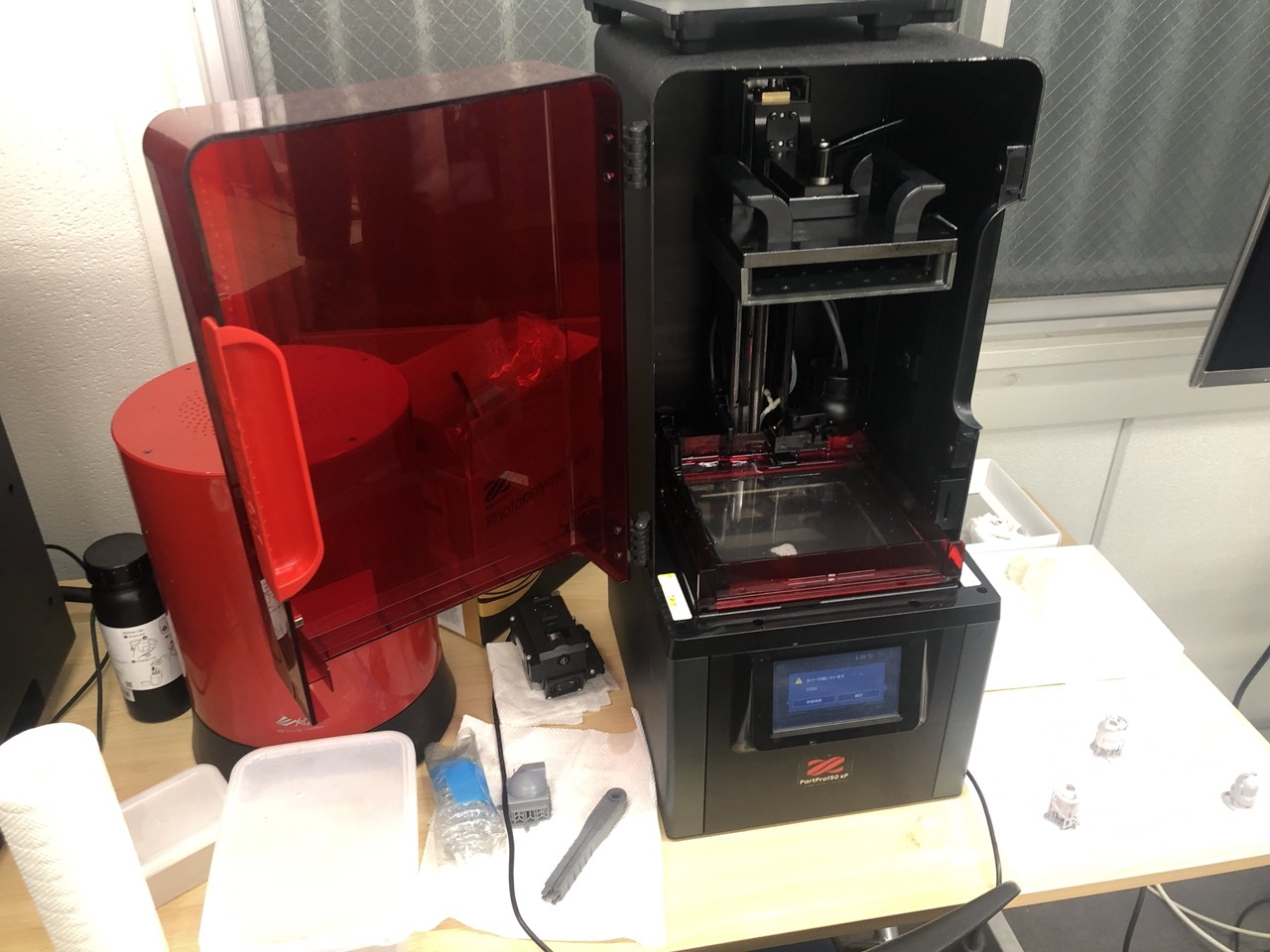

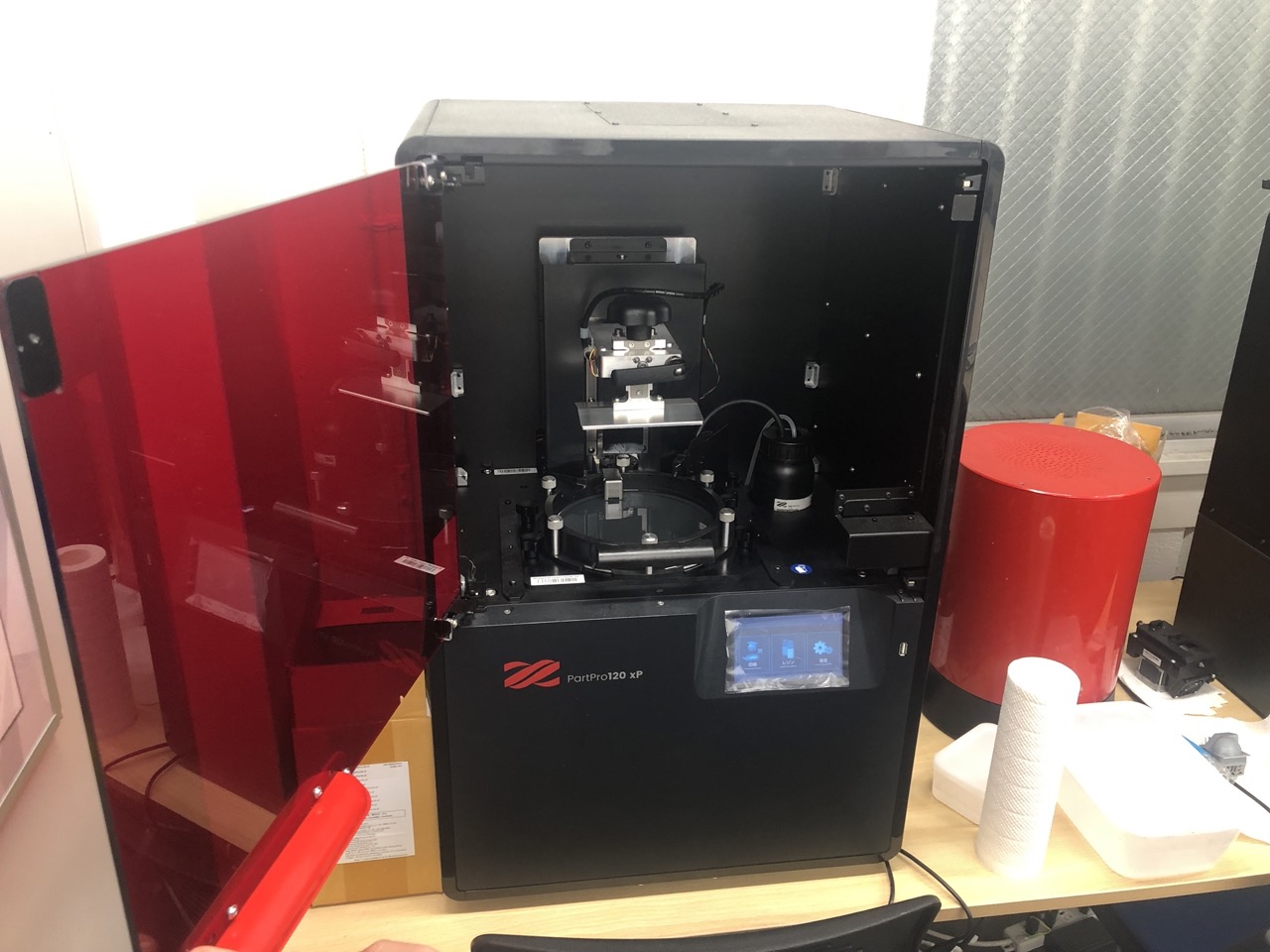

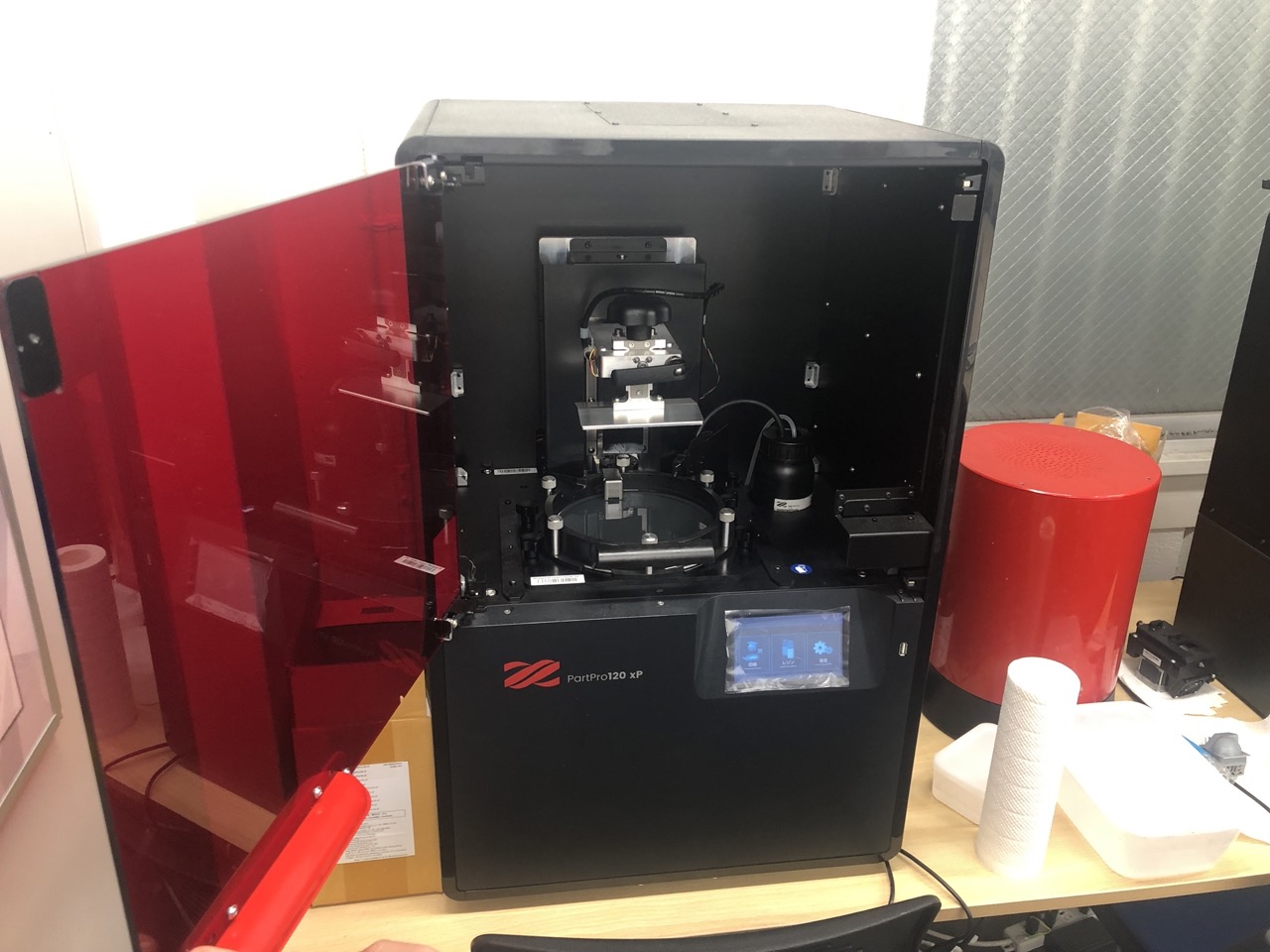

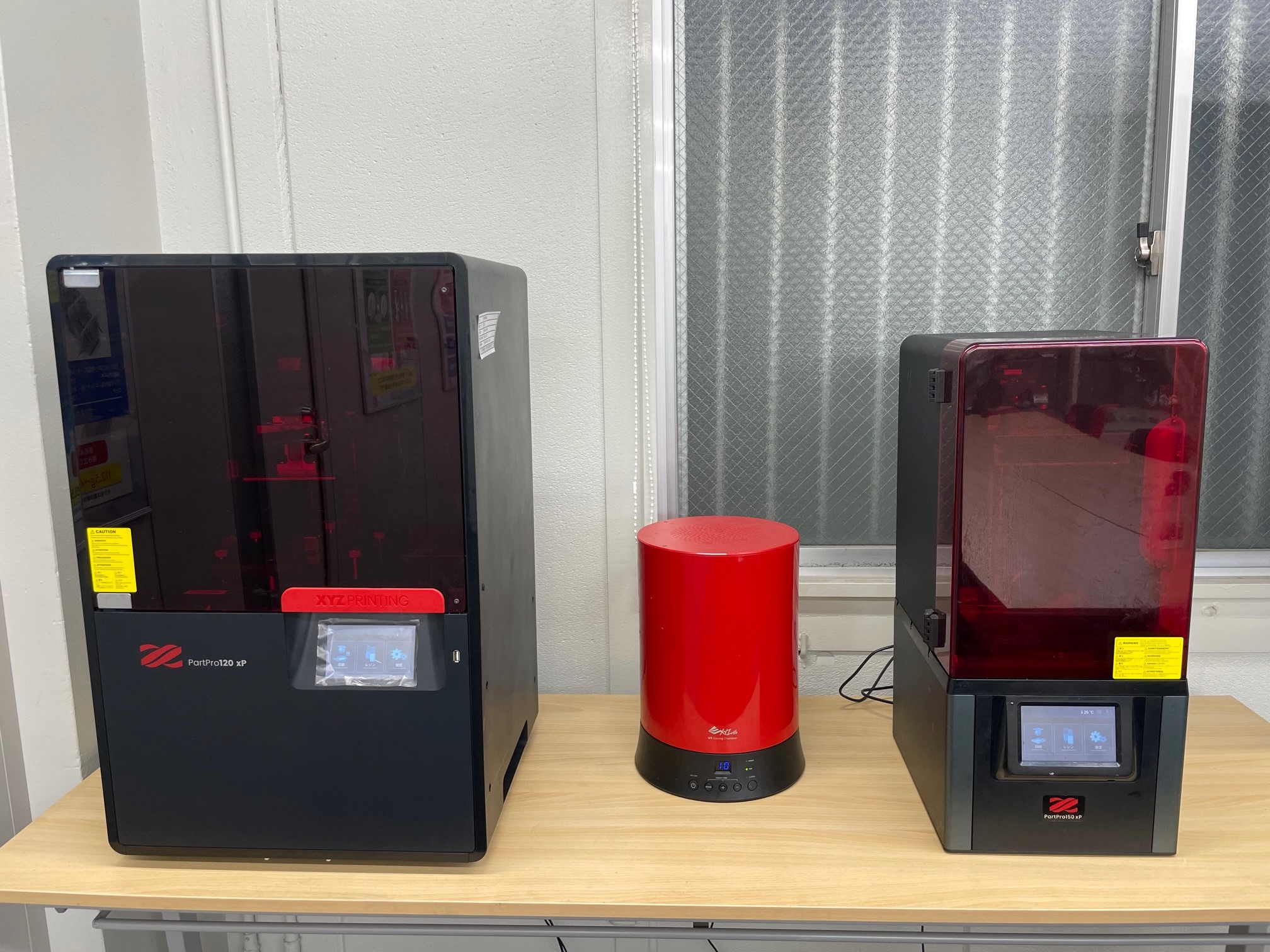

Made by us

▲SLA SLA is the acronym for Stereolithography Apparatus and an alias of Stereolithography. Especially, SLA is a system that emits a linear UV laser and gradually prints a layer. and DLP

SLA is the acronym for Stereolithography Apparatus and an alias of Stereolithography. Especially, SLA is a system that emits a linear UV laser and gradually prints a layer. and DLP DLP is the acronym for Digital Light Processing and an alias of Stereolithography. Especially, DLP is a system that emits a UV laser in the form of a plane with a projector and prints a layer at once.

DLP is the acronym for Digital Light Processing and an alias of Stereolithography. Especially, DLP is a system that emits a UV laser in the form of a plane with a projector and prints a layer at once.

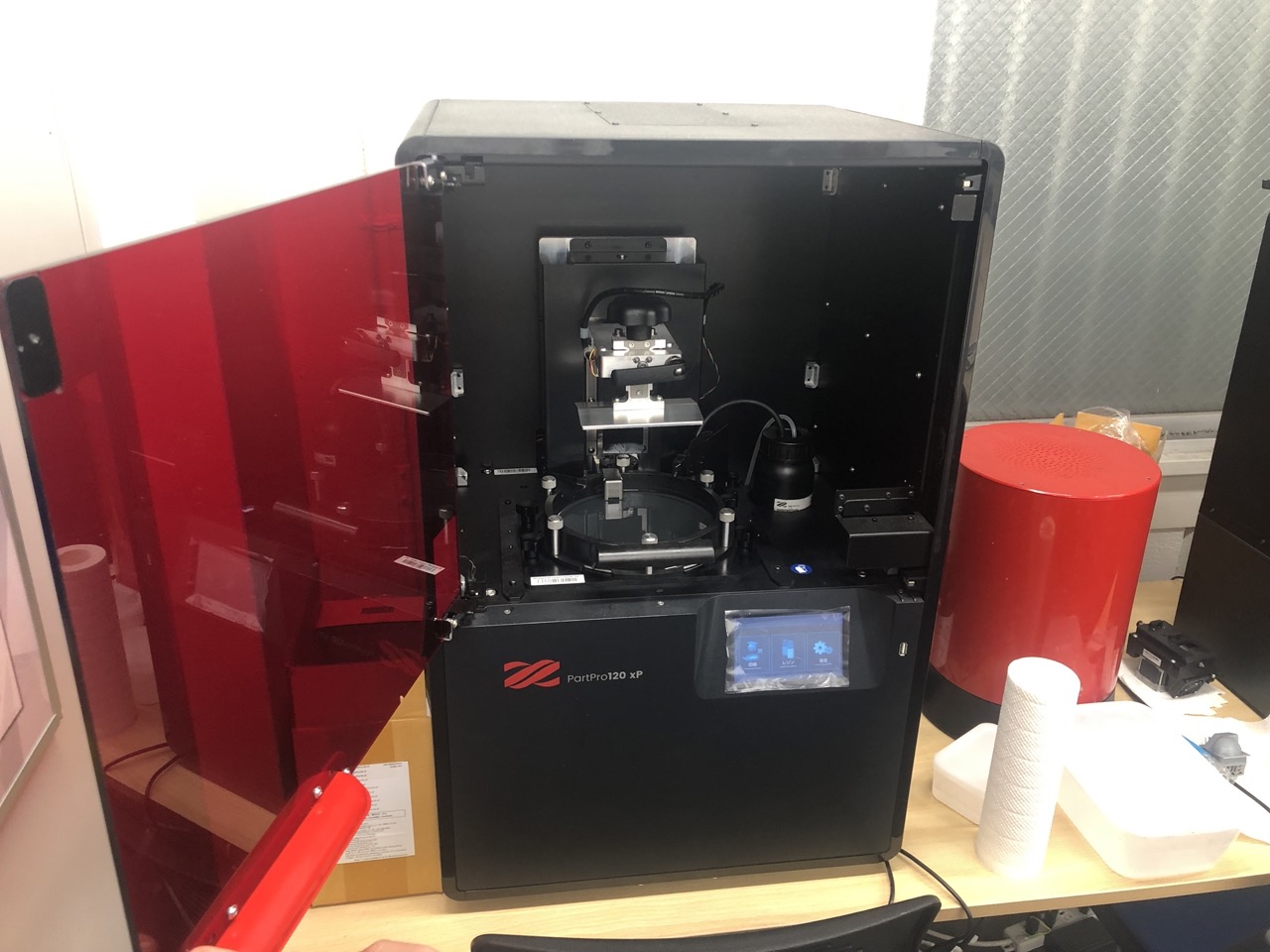

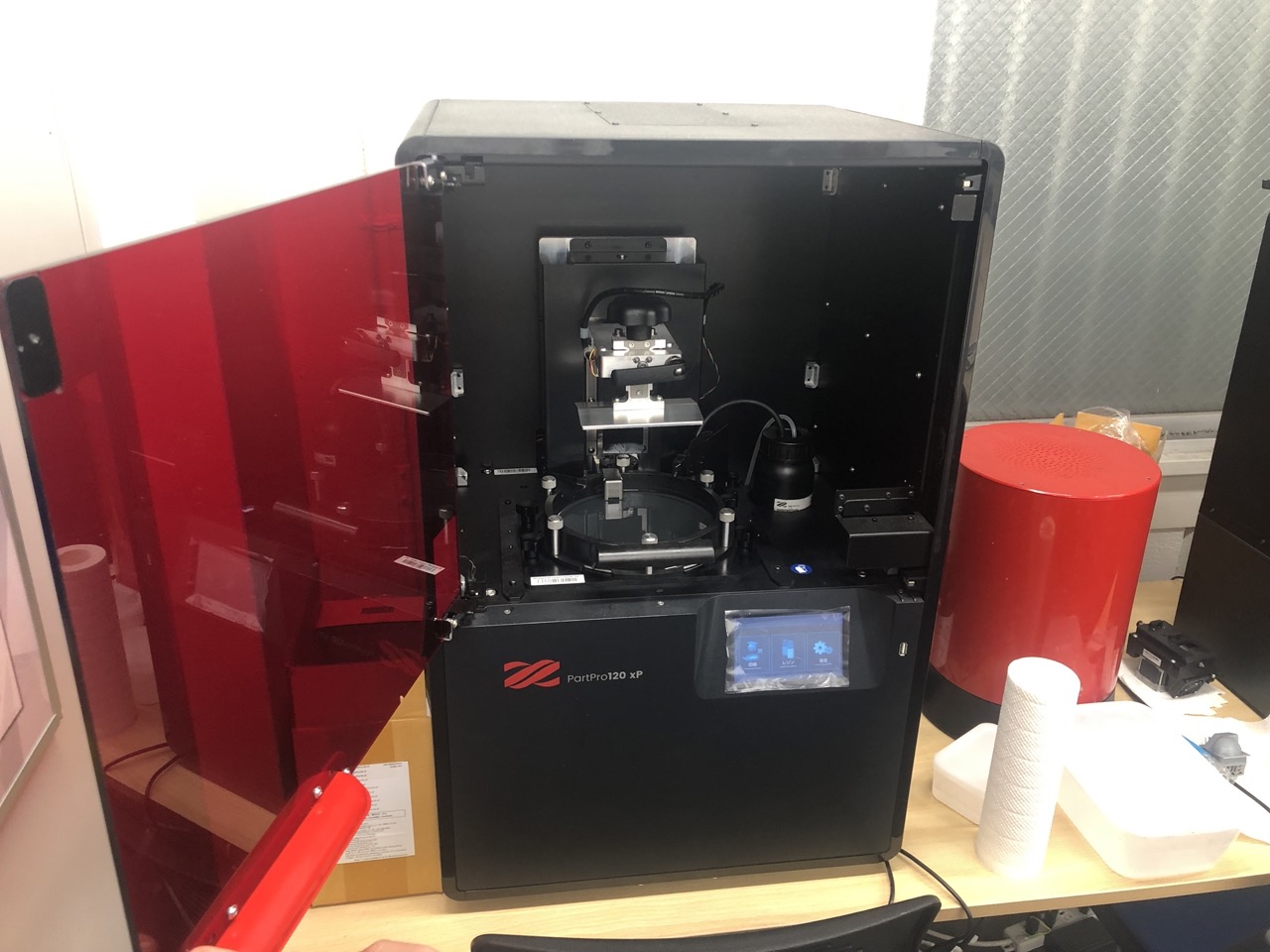

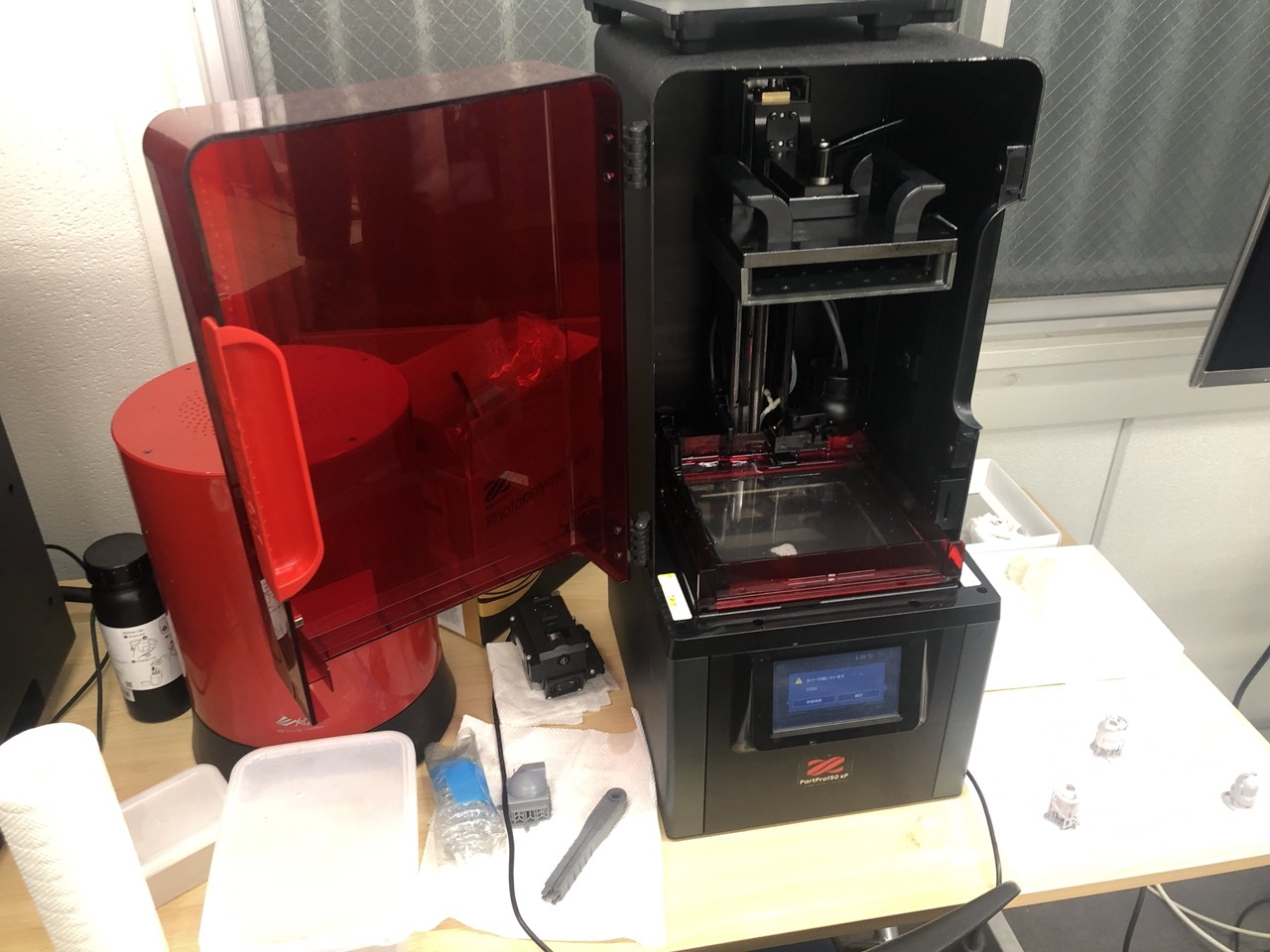

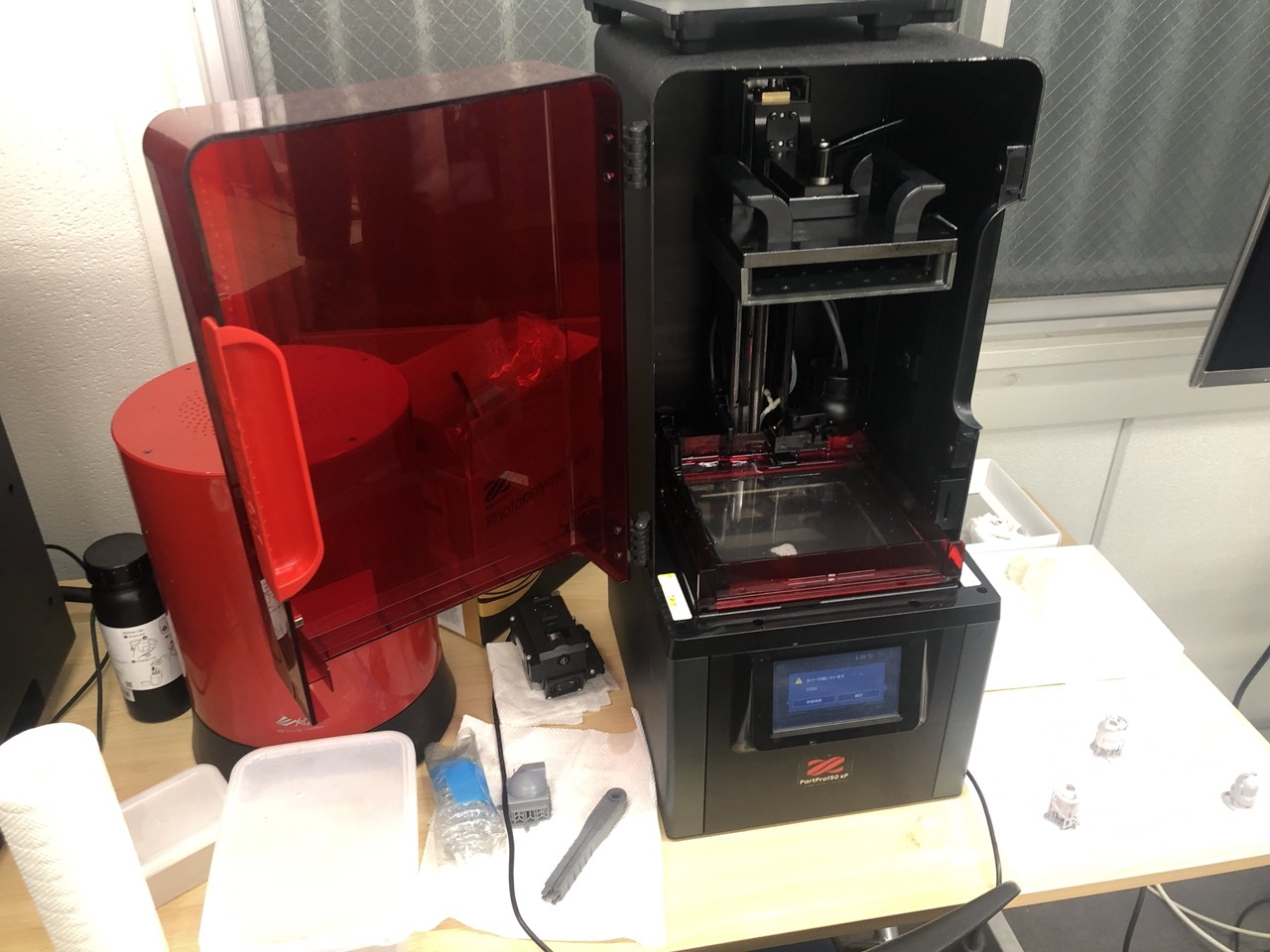

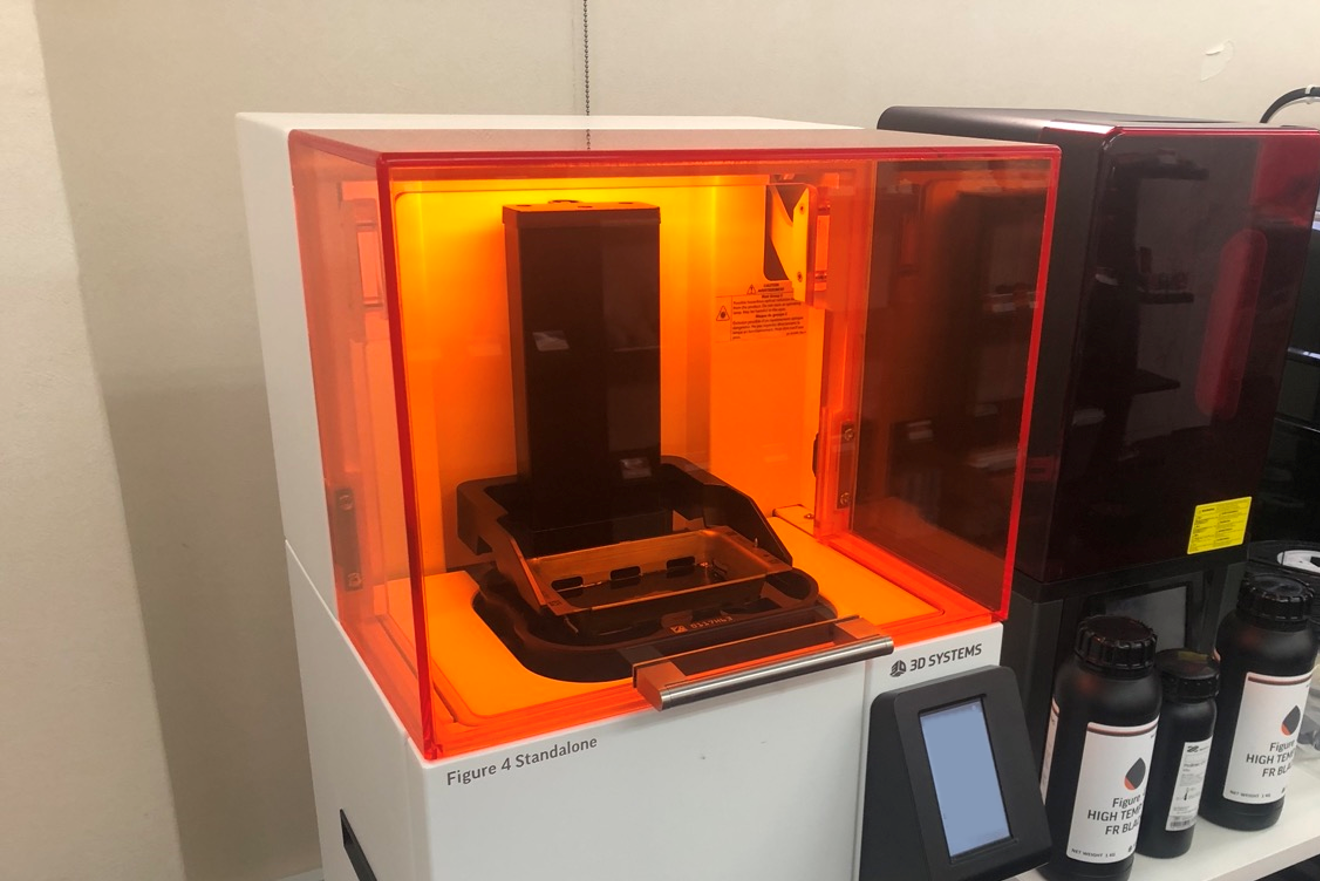

Provided by 3D Solution Center

▲On the left is DLP DLP is the acronym for Digital Light Processing and an alias of Stereolithography. Especially, DLP is a system that emits a UV laser in the form of a plane with a projector and prints a layer at once., right is SLA

DLP is the acronym for Digital Light Processing and an alias of Stereolithography. Especially, DLP is a system that emits a UV laser in the form of a plane with a projector and prints a layer at once., right is SLA SLA is the acronym for Stereolithography Apparatus and an alias of Stereolithography. Especially, SLA is a system that emits a linear UV laser and gradually prints a layer..

SLA is the acronym for Stereolithography Apparatus and an alias of Stereolithography. Especially, SLA is a system that emits a linear UV laser and gradually prints a layer..

DLP DLP is the acronym for Digital Light Processing and an alias of Stereolithography. Especially, DLP is a system that emits a UV laser in the form of a plane with a projector and prints a layer at once. emits UV laser from a projector, and LCDLCD is the acronym for Liquid Crystal Display and an alias of Stereolithography. Especially, LCD is a system that emits a UV laser in the form of a plane with a liquid crystal display and prints a layer at once. emits laser from a liquid crystal display.

DLP is the acronym for Digital Light Processing and an alias of Stereolithography. Especially, DLP is a system that emits a UV laser in the form of a plane with a projector and prints a layer at once. emits UV laser from a projector, and LCDLCD is the acronym for Liquid Crystal Display and an alias of Stereolithography. Especially, LCD is a system that emits a UV laser in the form of a plane with a liquid crystal display and prints a layer at once. emits laser from a liquid crystal display.

Stack each formed layer by moving the stage A stage is the foundation on which moldings are printed in a 3D printer. to Z-axis while printing.

A stage is the foundation on which moldings are printed in a 3D printer. to Z-axis while printing.

Place: 3D Solution Center

▲Picture of stacking layer by 3D printer

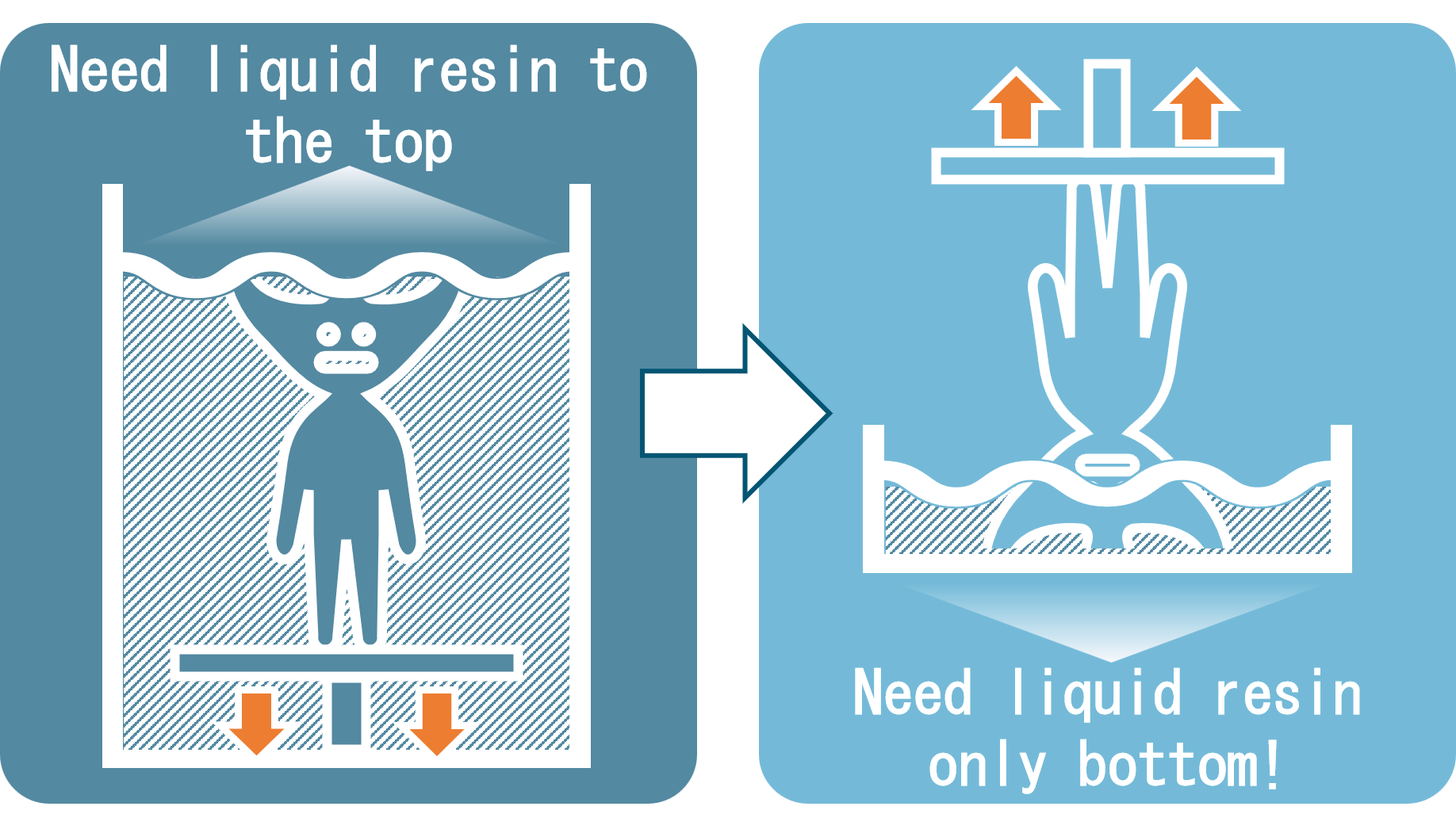

Most Stereolithography printers create objects based on the stage A stage is the foundation on which moldings are printed in a 3D printer. that is set upside of them.

A stage is the foundation on which moldings are printed in a 3D printer. that is set upside of them.

Therefore, they can print the whole object just by filling the bottom of the tank with liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling..

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling..

Made by us

▲Mechanism of saving liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling..

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling..

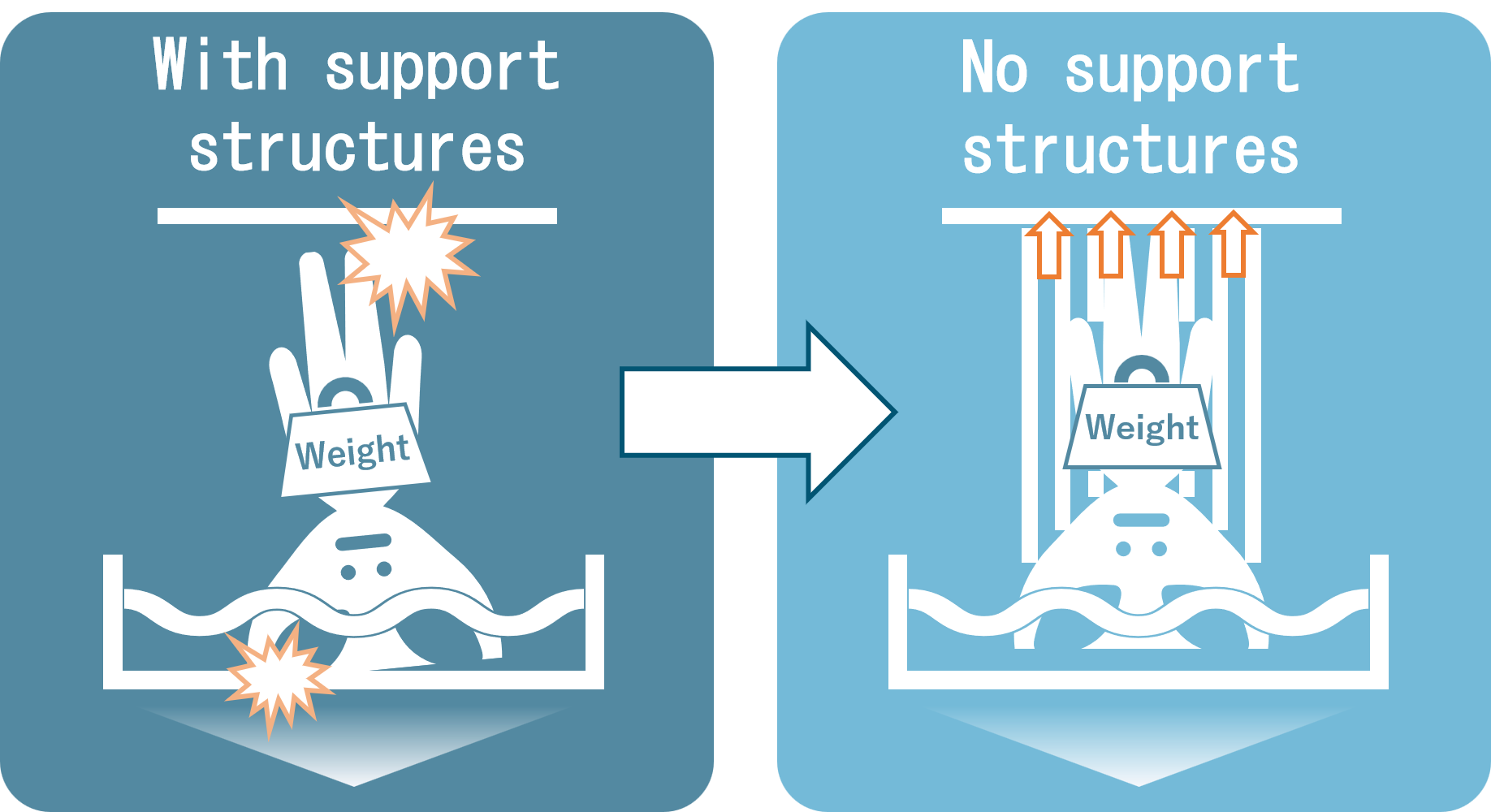

The UV laser is emitted from the bottom of the tank to the bottom of the printing object, and the object hand in midair. Therefore, support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. are necessary to prevent the object from falling.

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. are necessary to prevent the object from falling.

Made by us

▲Why support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. are necessary.

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. are necessary.

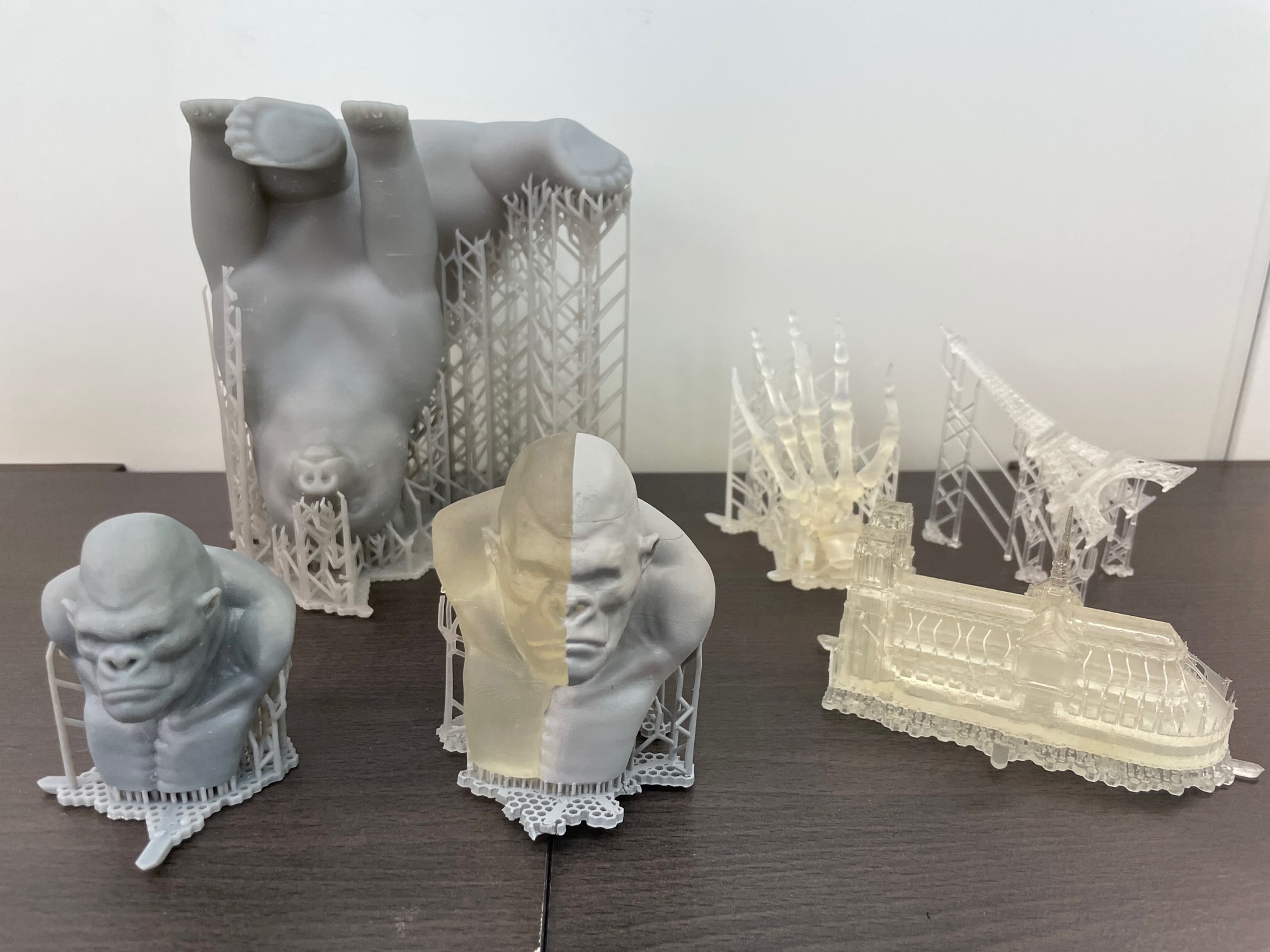

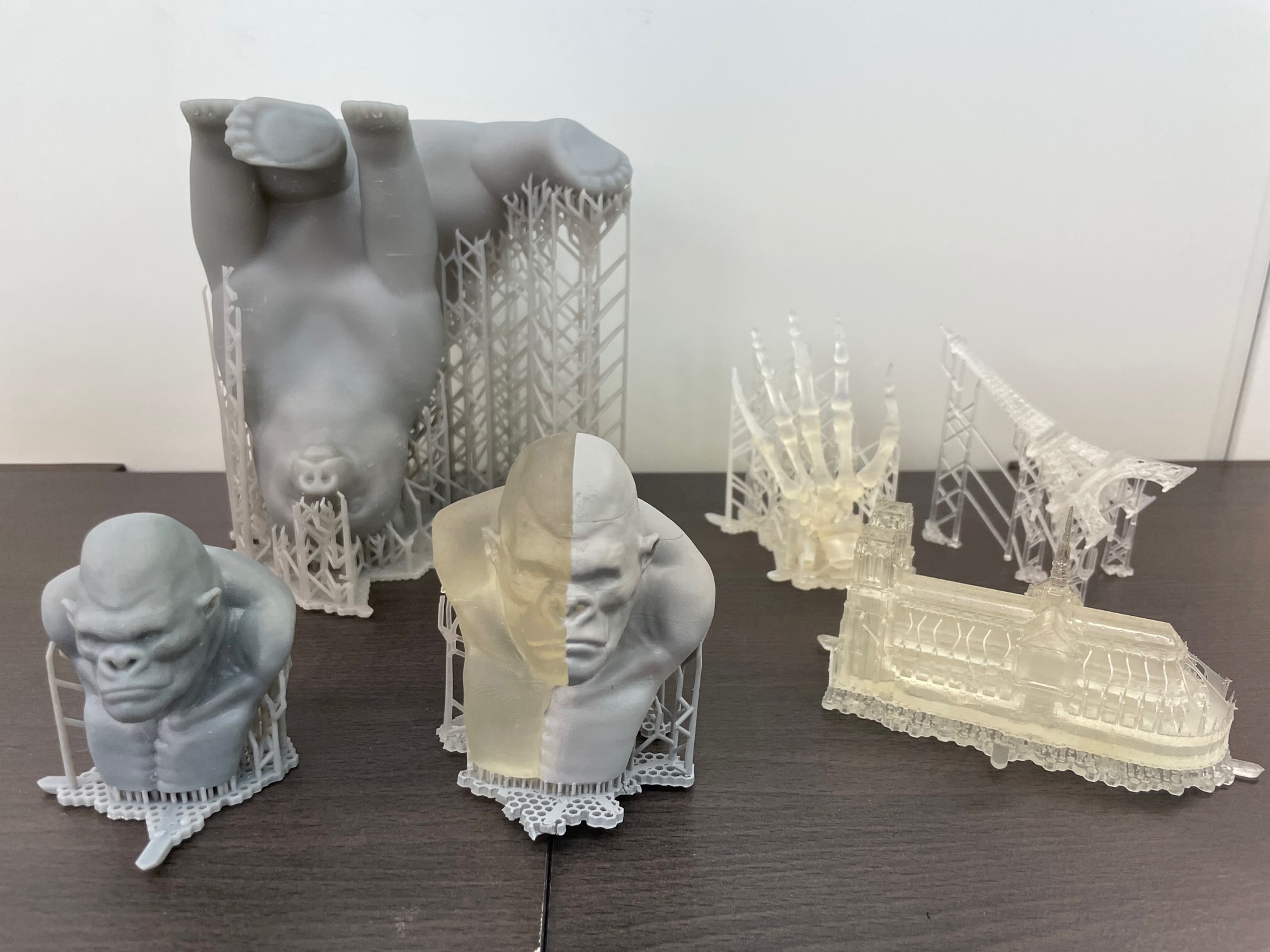

Provided by 3D Solution Center

▲Support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling.

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling.

This is how Stereolithography prints 3D objects.

Stereolithography needs to add two more steps to finalize 3D objects. They are called washing and post-curing Post-curing is the process of irradiating the modeled object with ultraviolet light after printing with a 3D printer such as the Stereolithography..

Post-curing is the process of irradiating the modeled object with ultraviolet light after printing with a 3D printer such as the Stereolithography..

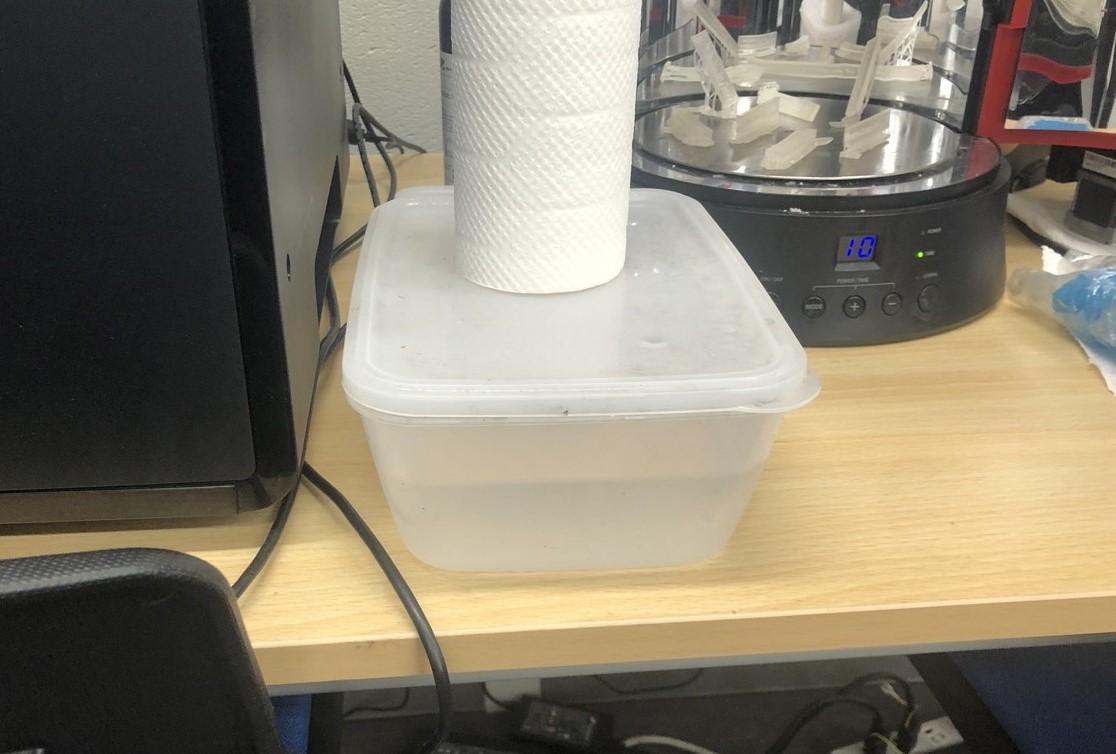

Washing mentioned here is a step to wash away unnecessary liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. adhered to printed objects. Usually, we use IPA, ethanol, or alcohol as washing liquid.

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. adhered to printed objects. Usually, we use IPA, ethanol, or alcohol as washing liquid.

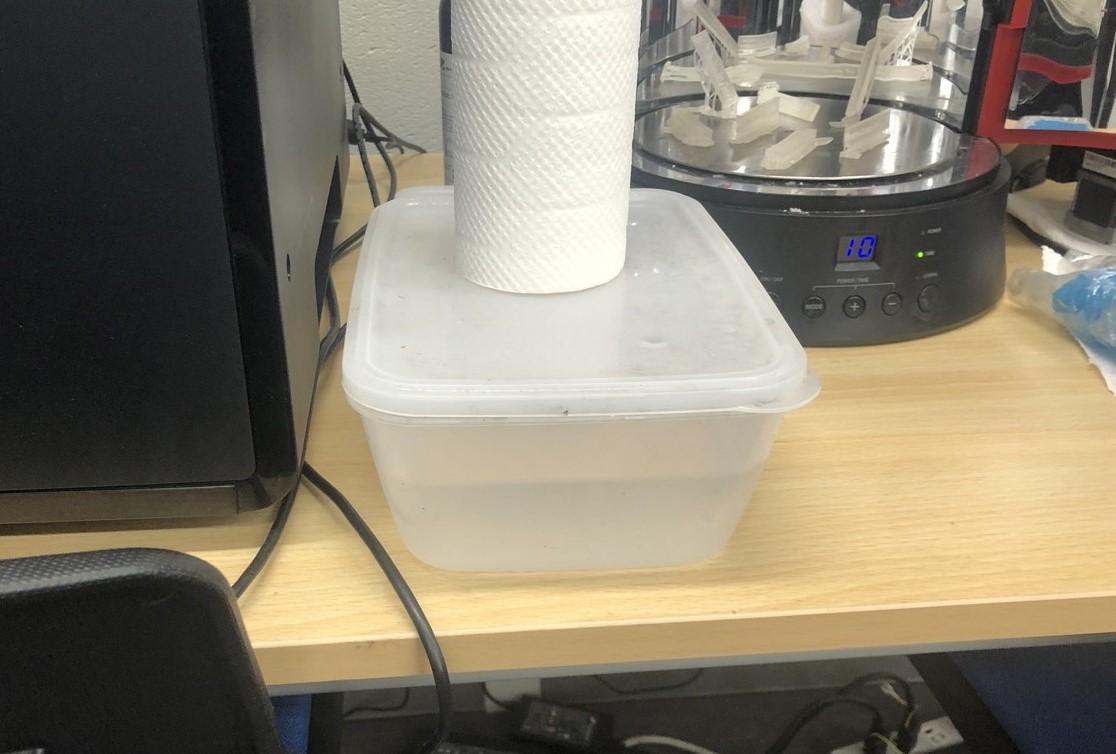

Place: 3D Solution Center

▲Picture of the case of washing liquid.

Post-curing Post-curing is the process of irradiating the modeled object with ultraviolet light after printing with a 3D printer such as the Stereolithography. is a step to emit more UV laser into printed objects to solidify them completely. This step makes the objects sturdier and prevents them from bending.

Post-curing is the process of irradiating the modeled object with ultraviolet light after printing with a 3D printer such as the Stereolithography. is a step to emit more UV laser into printed objects to solidify them completely. This step makes the objects sturdier and prevents them from bending.

Place: 3D Solution Center

▲The machine for post-curing Post-curing is the process of irradiating the modeled object with ultraviolet light after printing with a 3D printer such as the Stereolithography..

Post-curing is the process of irradiating the modeled object with ultraviolet light after printing with a 3D printer such as the Stereolithography..

We will introduce the feature of Stereolithography.

The surface becomes smooth thanks to the material, liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling..

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling..

Place: 3D Solution Center

▲Picture of the objects printed with Stereolithography.

We can print more elaborate objects with Stereolithography than the nozzle A nozzle is a component that extrudes filament (resin) and prints it on the stage. of Fused Filament Fabrication

A nozzle is a component that extrudes filament (resin) and prints it on the stage. of Fused Filament Fabrication Fused Filament Fabrication is a method that draws each layer and stacks it by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle. because it solidifies objects with a UV laser.

Fused Filament Fabrication is a method that draws each layer and stacks it by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle. because it solidifies objects with a UV laser.

Can use clear resin and print beautifully transparent objects.

Place: 3D Solution Center

▲Picture of the objects printed with clear resin.

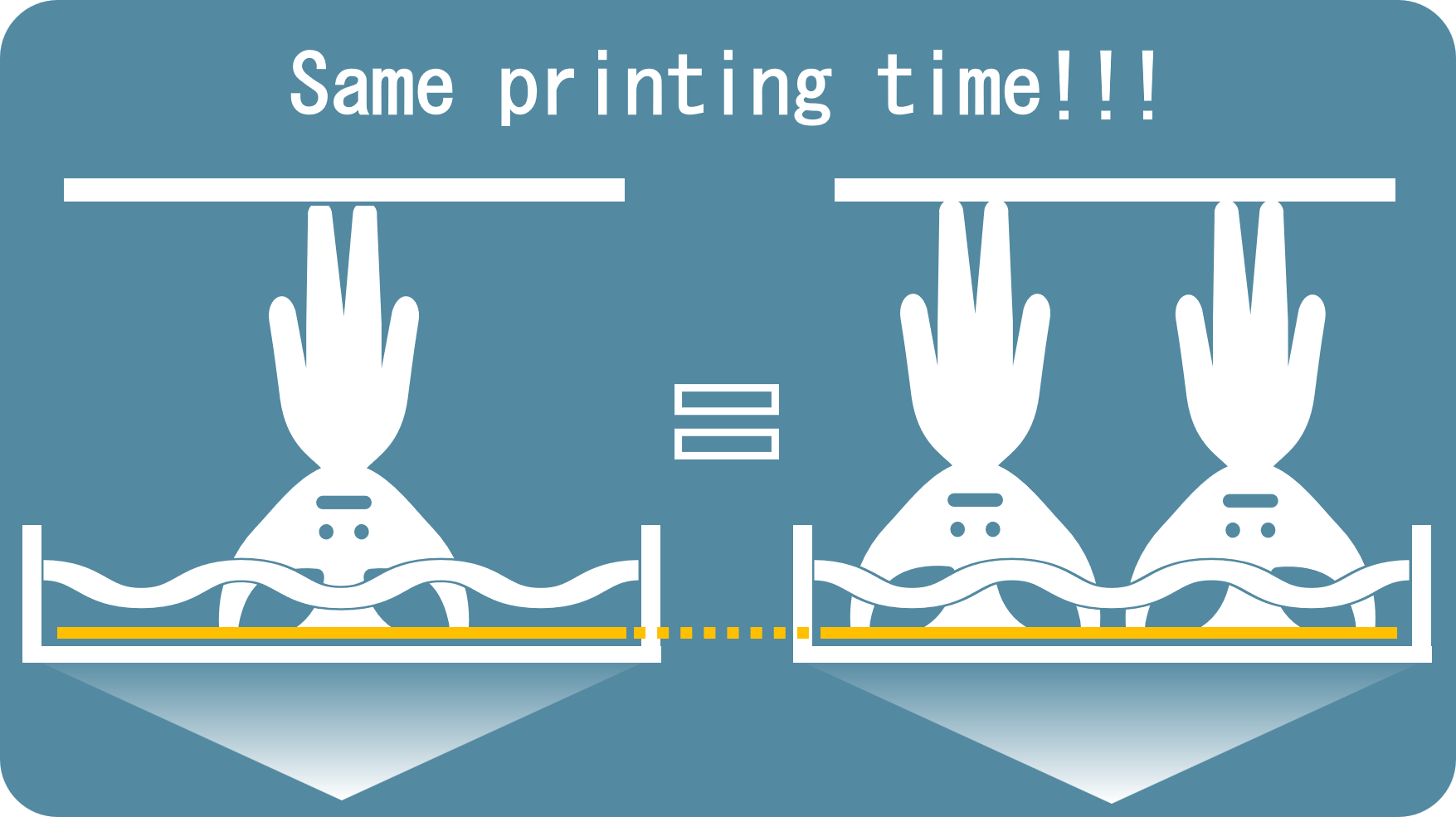

The systems of DLP DLP is the acronym for Digital Light Processing and an alias of Stereolithography. Especially, DLP is a system that emits a UV laser in the form of a plane with a projector and prints a layer at once. and LCDLCD is the acronym for Liquid Crystal Display and an alias of Stereolithography. Especially, LCD is a system that emits a UV laser in the form of a plane with a liquid crystal display and prints a layer at once. can form objects fast. Printing in the direction of the XY axis is stable even when they make a large object because the systems emit a UV laser in the form of a plane and print a layer at once.

DLP is the acronym for Digital Light Processing and an alias of Stereolithography. Especially, DLP is a system that emits a UV laser in the form of a plane with a projector and prints a layer at once. and LCDLCD is the acronym for Liquid Crystal Display and an alias of Stereolithography. Especially, LCD is a system that emits a UV laser in the form of a plane with a liquid crystal display and prints a layer at once. can form objects fast. Printing in the direction of the XY axis is stable even when they make a large object because the systems emit a UV laser in the form of a plane and print a layer at once.

Made by us

▲Why printing speed is stable.

The liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. might cause a skin rash if you touch it. The liquid is harmful to our bodies. Follow the directions of the manual for your safety. You are required to clean the printer carefully after printing.

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. might cause a skin rash if you touch it. The liquid is harmful to our bodies. Follow the directions of the manual for your safety. You are required to clean the printer carefully after printing.

It takes time and effort to print with the printer because you are required to prepare for printing in advance, such as setting liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. and adjusting the stage

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. and adjusting the stage A stage is the foundation on which moldings are printed in a 3D printer., and you also need to clean up the printer. It’s necessary to do post-curing

A stage is the foundation on which moldings are printed in a 3D printer., and you also need to clean up the printer. It’s necessary to do post-curing Post-curing is the process of irradiating the modeled object with ultraviolet light after printing with a 3D printer such as the Stereolithography..

Post-curing is the process of irradiating the modeled object with ultraviolet light after printing with a 3D printer such as the Stereolithography..

Stereolithography is more expensive than Fused Filament Fabrication Fused Filament Fabrication is a method that draws each layer and stacks it by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle., and liquid resin

Fused Filament Fabrication is a method that draws each layer and stacks it by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle., and liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. is also expensive.

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. is also expensive.

The majority of liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. is oily and a little weak.

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. is oily and a little weak.

There is a possibility of falling a big and heavy object because of hanging.

Stereolithography is the best 3D printer for people interested in objects' good appearances because it can produce smooth surface objects and elaborate objects.

On the other hand, stereolithography is less convenient because it needs liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. and is not relatively safe. Also, it takes time and effort to use it. Additionally, it is a little expensive as a home-use 3D printer

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. and is not relatively safe. Also, it takes time and effort to use it. Additionally, it is a little expensive as a home-use 3D printer A home-use 3D printer is one intended for personal purchase. Although home-use 3D printers are less precise than industrial-use printers, they are less expensive, with some printers costing less than 50,000 yen..

A home-use 3D printer is one intended for personal purchase. Although home-use 3D printers are less precise than industrial-use printers, they are less expensive, with some printers costing less than 50,000 yen..

These are the features of Stereolithography.

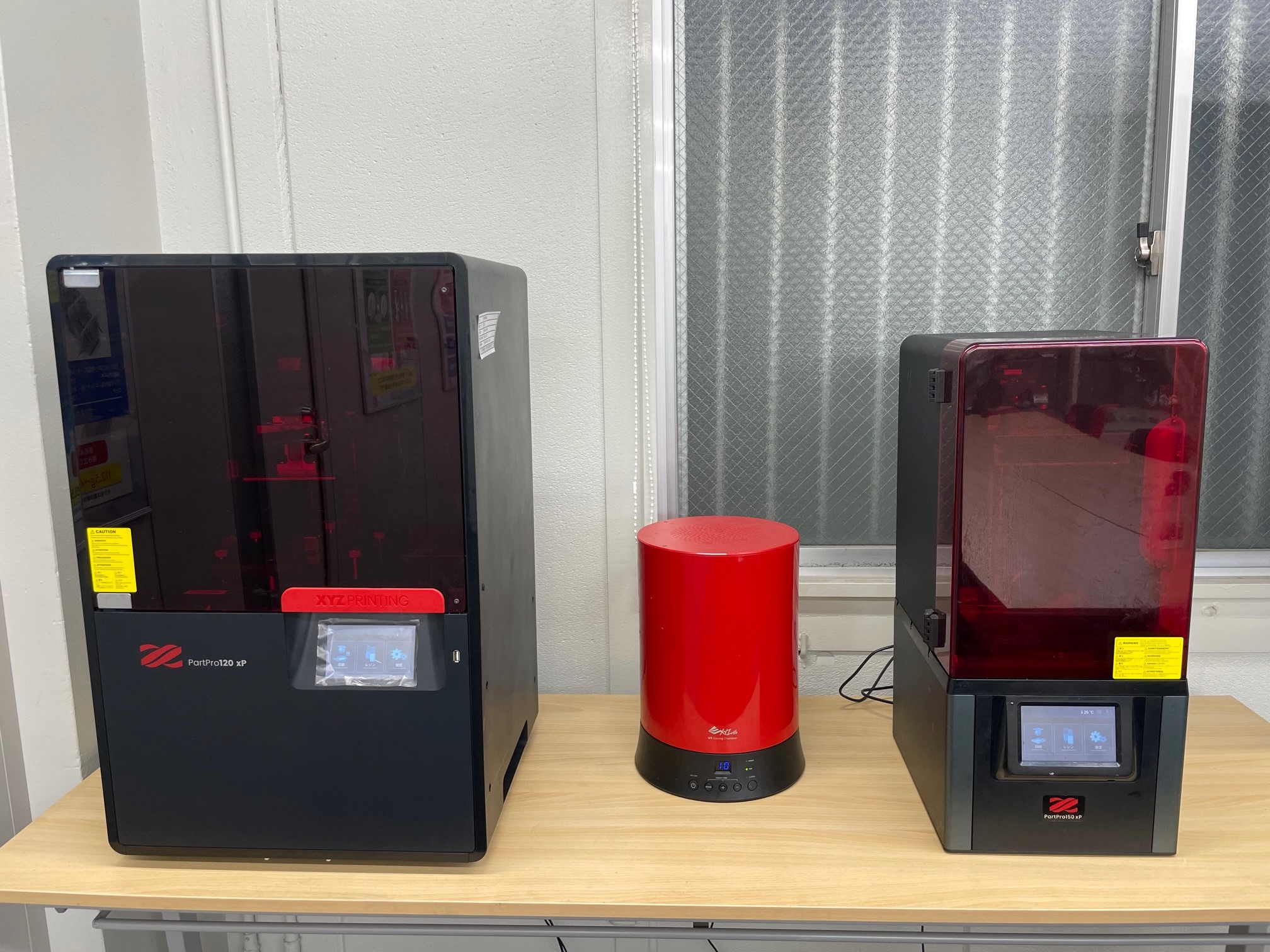

We will show some pictures of Stereolithography and its printed objects.

Stereolithography

Place: 3D Solution Center

Picture of the case of liquid resin.

Place: 3D Solution Center

Structure of Stereolithography.

Place: 3D Solution Center

The picture is a tank emitting a UV laser from its bottom.

Place: 3D Solution Center

On the left is DLP, right is SLA.

Provided by 3D Solution Center

Picture of stacking layer by 3D printer.

Place: 3D Solution Center

Support structures

Provided by 3D Solution Center

Picture of the case of washing liquid.

Place: 3D Solution Center

The machine for post-curing.

Place: 3D Solution Center

Picture of the objects printed with Stereolithography.

Place: 3D Solution Center

Picture of the objects printed with clear resin.

Place: 3D Solution Center