Selective Laser Sintering

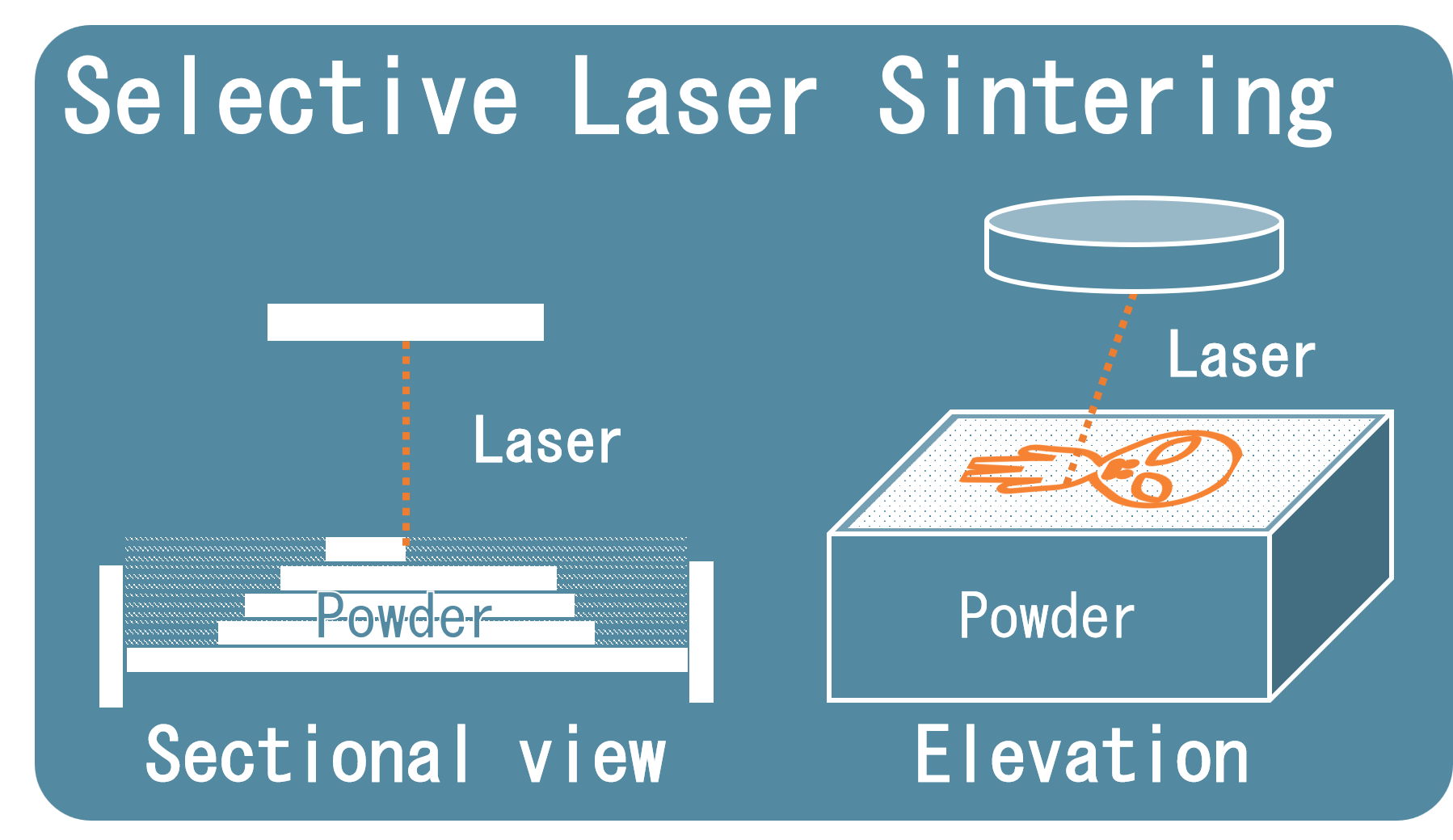

Selective Laser Sintering is a method that draws each layer by emitting a laser to the flattened powder and solidifying them. We’ll introduce the feature and printing process of Selective Laser Sintering on this page.

Table of Contents

The table is the basic information list of Selective Laser Sintering.

| ISO standards | Powder Bed Fusion |

|---|---|

| Aliases | SLS, DMLS |

| Cost | Expensive |

| Performance | Good |

How can we print 3D objects with Selective Laser Sintering?

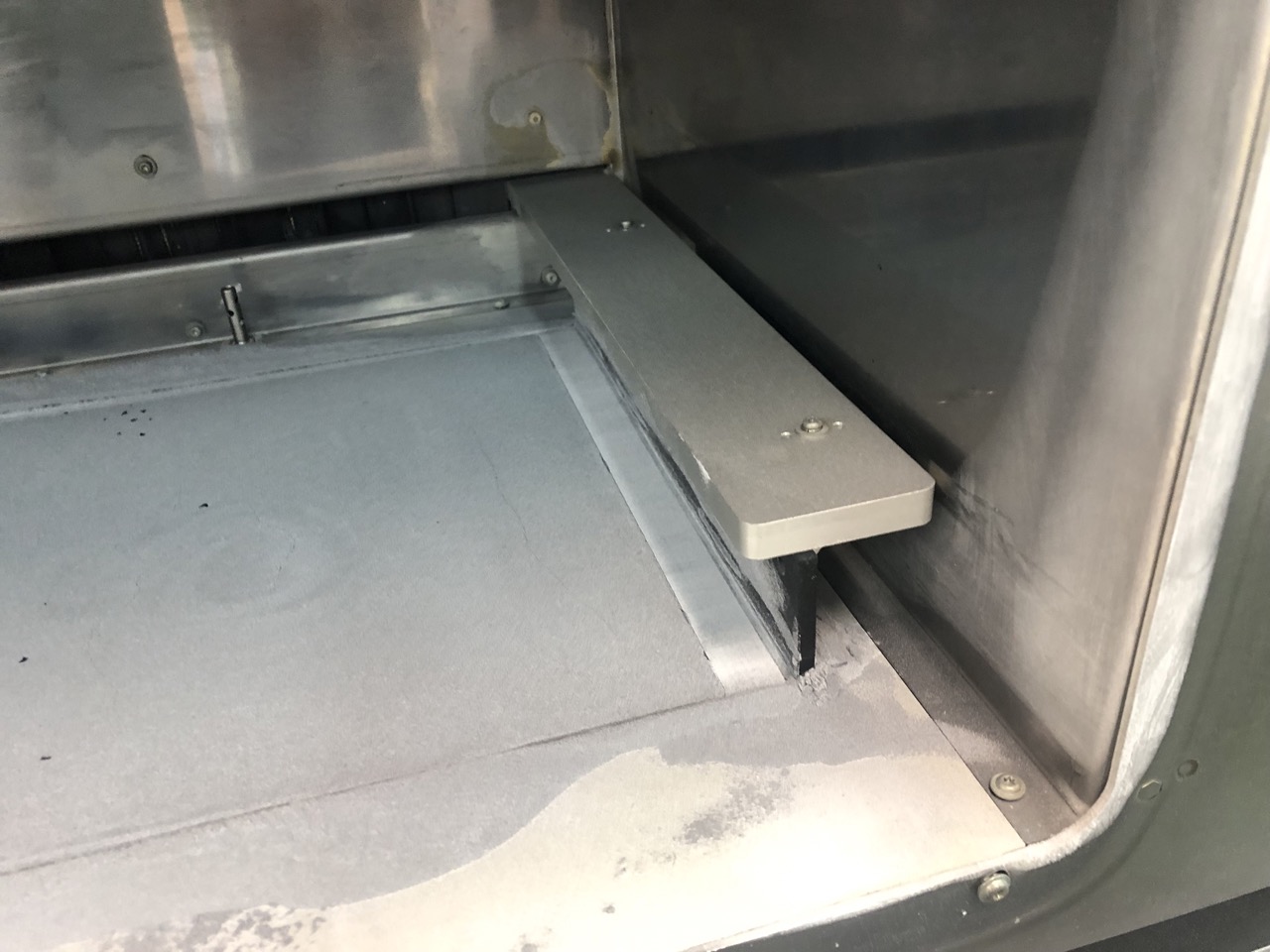

A tank with powder as material in it and the stage A stage is the foundation on which moldings are printed in a 3D printer., which is the printing space, are lined up on either side of a plane.

A stage is the foundation on which moldings are printed in a 3D printer., which is the printing space, are lined up on either side of a plane.

Place: 3D Solution Center

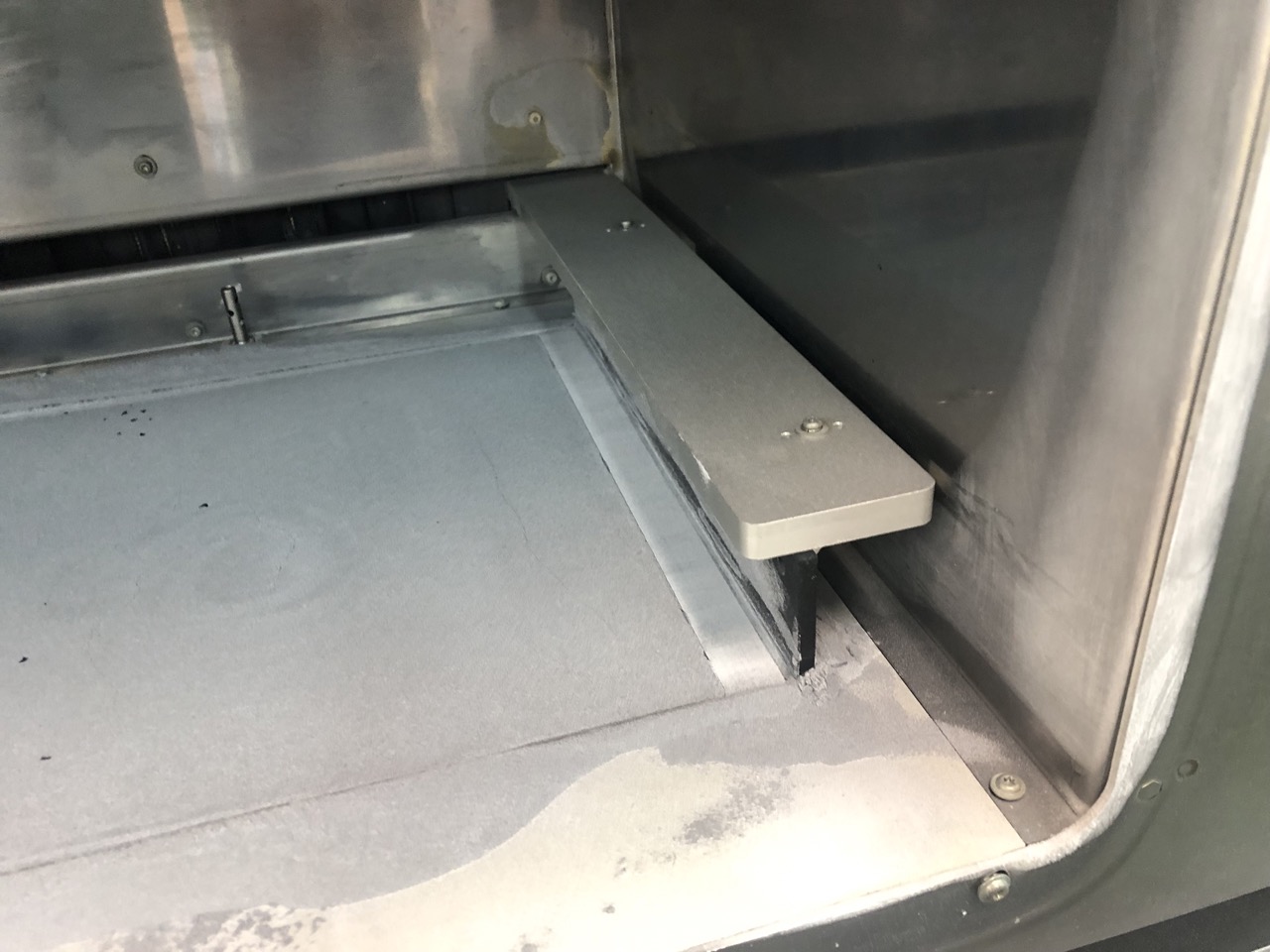

The appearance of the inside. From left to right, are the stage A stage is the foundation on which moldings are printed in a 3D printer. and tank.

A stage is the foundation on which moldings are printed in a 3D printer. and tank.

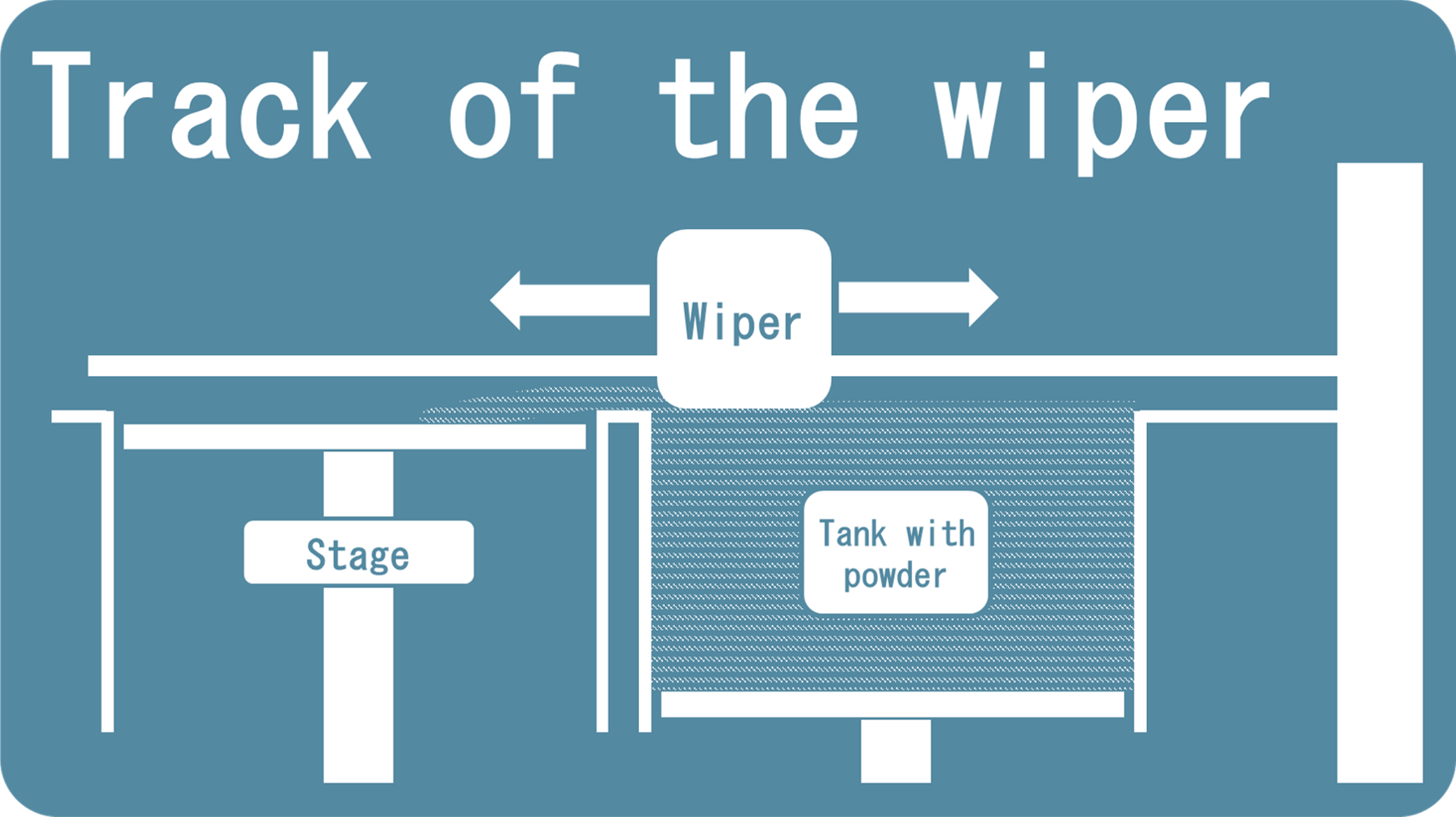

The powder set in the tank is translated to a stage A stage is the foundation on which moldings are printed in a 3D printer. with a mechanism like a windscreen wiper and makes a thin layer.

A stage is the foundation on which moldings are printed in a 3D printer. with a mechanism like a windscreen wiper and makes a thin layer.

Made by us

▲Track of the mechanism

Place: 3D Solution Center

▲A mechanism like a windscreen wiper

The device prints a layer by emitting a laser into flattened powder on the stage A stage is the foundation on which moldings are printed in a 3D printer. and solidifies it.

A stage is the foundation on which moldings are printed in a 3D printer. and solidifies it.

Made by us

▲Structure of Selective Laser Sintering

Place: 3D Solution Center

▲A hole for emitting laser

The solidified powder descends with around powder for one layer and then the new powder adds to the top of them in a flattened form. And they have solidified again by emitting a laser.

The 3D object is created by repeating this process and stacking each layer.

Place: 3D Solution Center

▲Printed objects with Selective Laser Sintering

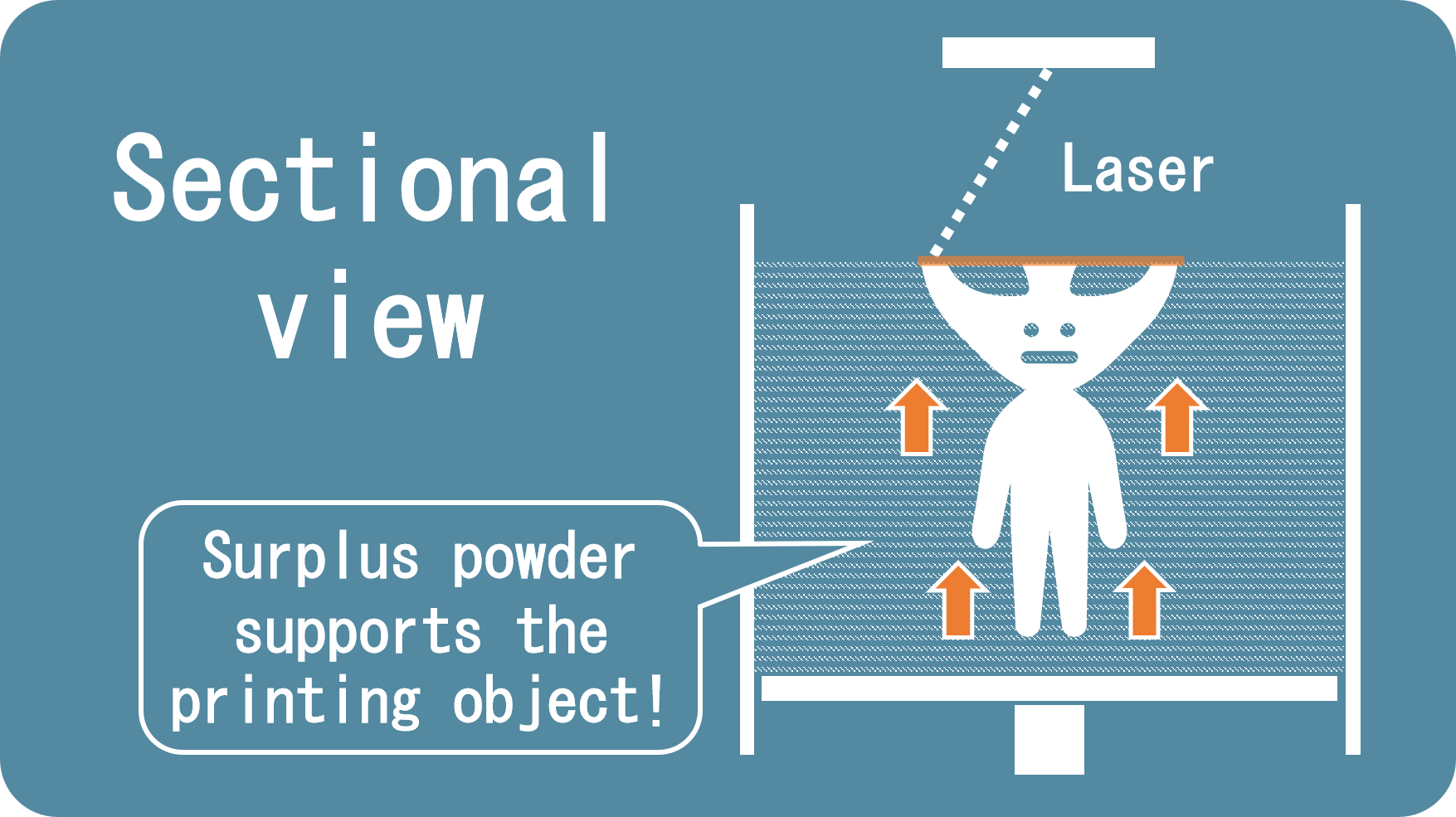

By the way, you don't have to print support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. because the extra powder accumulates at the bottom of the printing object.

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. because the extra powder accumulates at the bottom of the printing object.

This is how Selective Laser Sintering prints 3D objects.

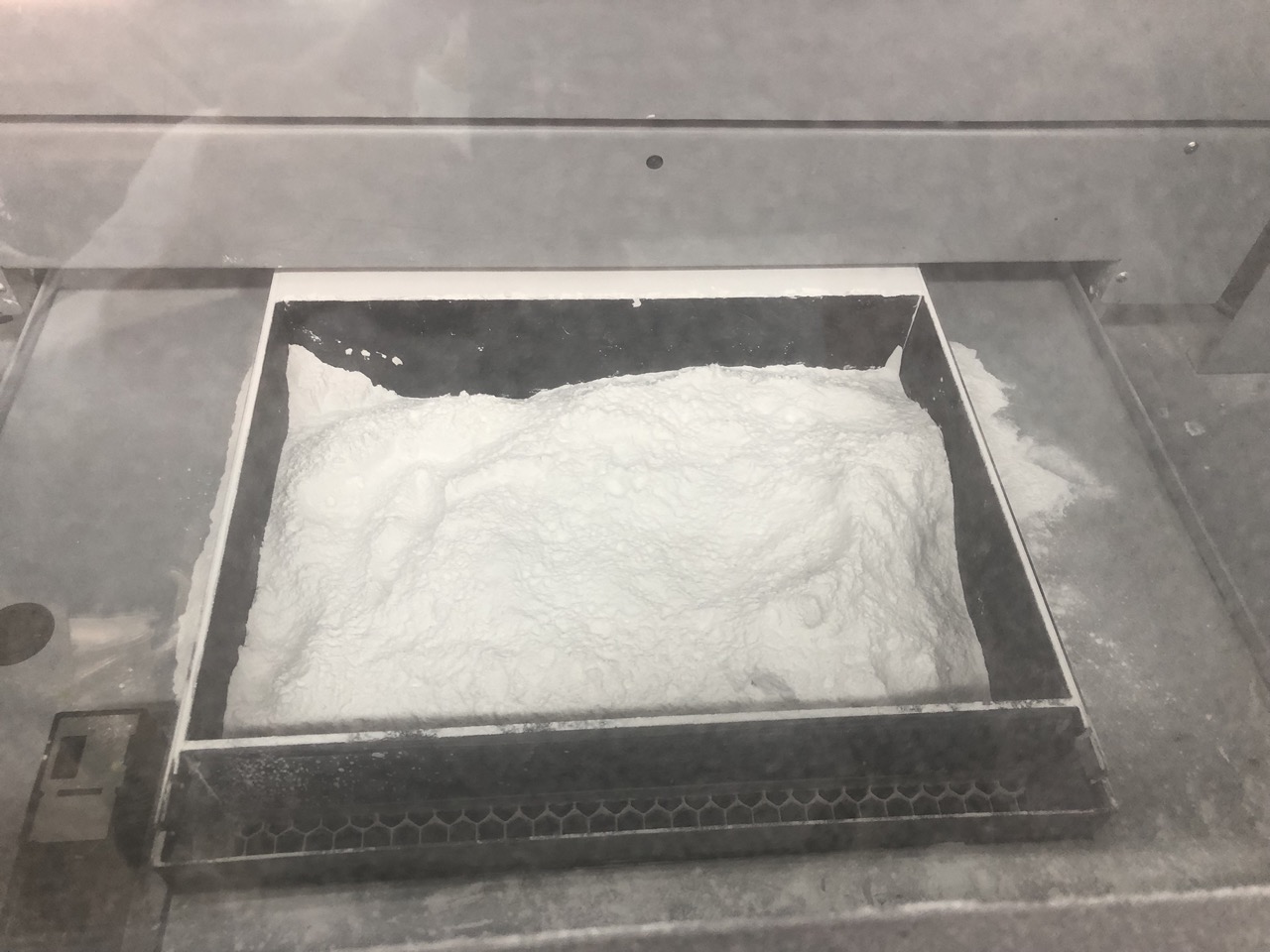

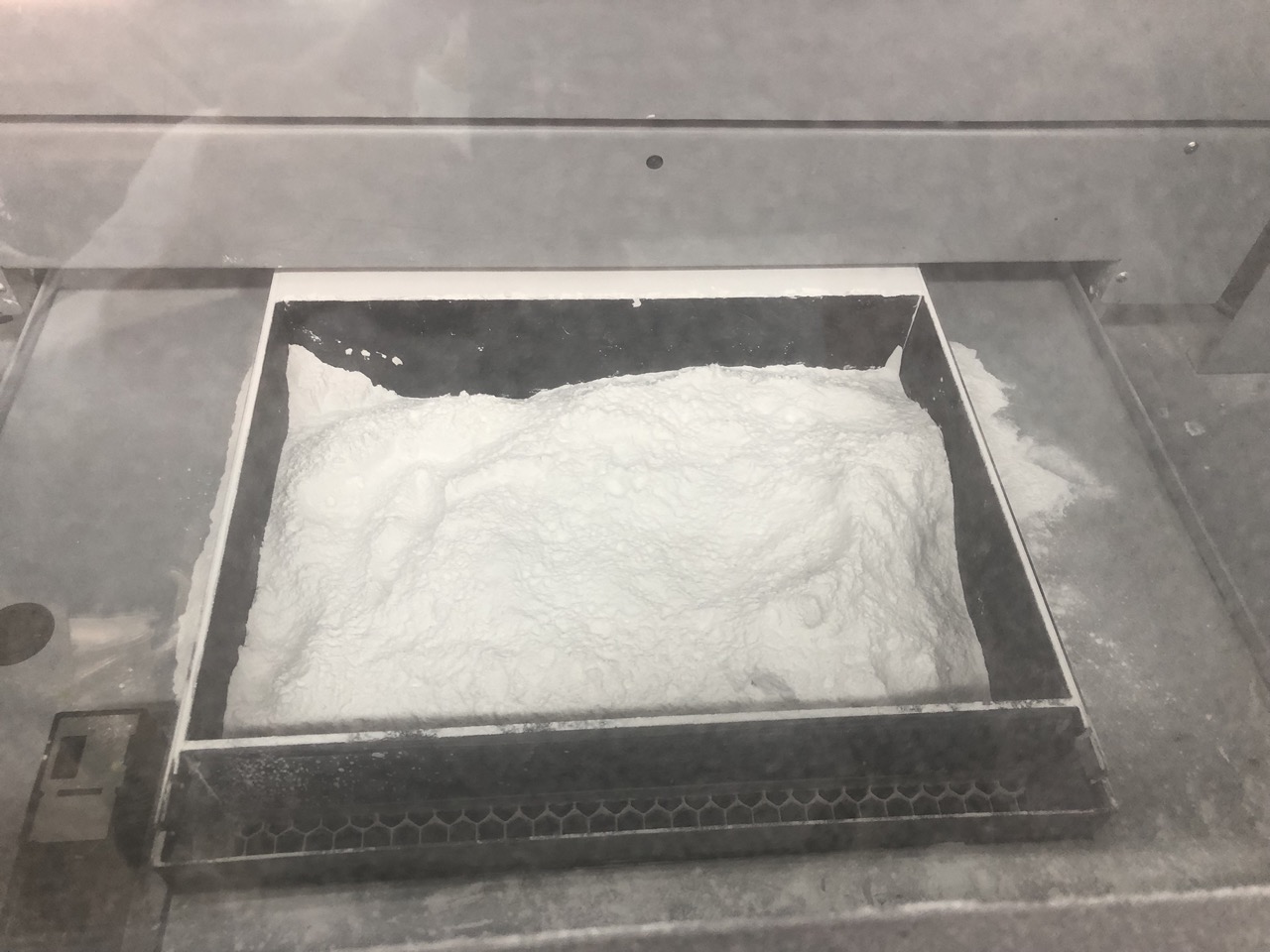

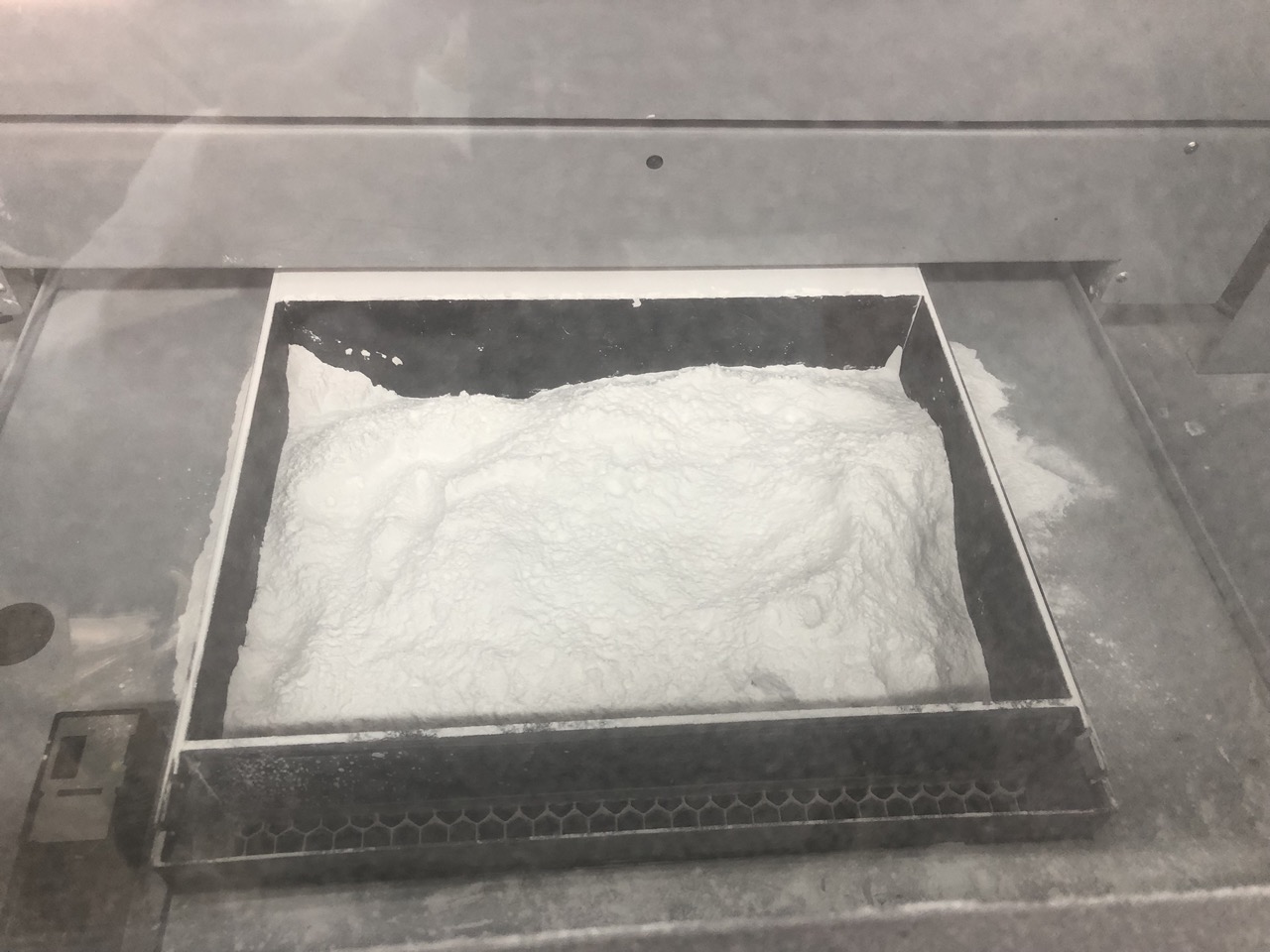

You have to clean the printed object after printing because the unsolidified powder surrounds it if you print with Selective Laser Sintering or Binder Jetting Binder Jetting is a method that draws each layer by emitting binder from the head to the flattened powder and solidifies them. It is, in some cases, categorized as MultiJet Printing..

Binder Jetting is a method that draws each layer by emitting binder from the head to the flattened powder and solidifies them. It is, in some cases, categorized as MultiJet Printing..

Place: 3D Solution Center

▲Powder (For Binder Jetting Binder Jetting is a method that draws each layer by emitting binder from the head to the flattened powder and solidifies them. It is, in some cases, categorized as MultiJet Printing.)

Binder Jetting is a method that draws each layer by emitting binder from the head to the flattened powder and solidifies them. It is, in some cases, categorized as MultiJet Printing.)

First, you move the printed objects surrounded by surplus powder into a cube box to carry it to the depowdering station In Selective Laser Sintering, Binder Jetting, a device that removes and reuses excess powder adhered after printing is completed..

In Selective Laser Sintering, Binder Jetting, a device that removes and reuses excess powder adhered after printing is completed..

Place: 3D Solution Center

▲Cube box that moves the printed object

The device can extrude the objects surrounded by powder into a set cube box on the stage A stage is the foundation on which moldings are printed in a 3D printer..

A stage is the foundation on which moldings are printed in a 3D printer..

After moving to the depowdering station In Selective Laser Sintering, Binder Jetting, a device that removes and reuses excess powder adhered after printing is completed., you pick out the printed object from a cube box and remove the surplus powder with a brush or air blow gun.

In Selective Laser Sintering, Binder Jetting, a device that removes and reuses excess powder adhered after printing is completed., you pick out the printed object from a cube box and remove the surplus powder with a brush or air blow gun.

Place: 3D Solution Center

▲Depowdering station In Selective Laser Sintering, Binder Jetting, a device that removes and reuses excess powder adhered after printing is completed.

In Selective Laser Sintering, Binder Jetting, a device that removes and reuses excess powder adhered after printing is completed.

You can recycle the surplus powder that surrounds printed objects for the next time. You isolate useful powder by using the mechanism of depowdering station In Selective Laser Sintering, Binder Jetting, a device that removes and reuses excess powder adhered after printing is completed. or vacuum cleaner with that attached dedicated mechanism.

In Selective Laser Sintering, Binder Jetting, a device that removes and reuses excess powder adhered after printing is completed. or vacuum cleaner with that attached dedicated mechanism.

Place: 3D Solution Center

▲The mechanism of depowdering station In Selective Laser Sintering, Binder Jetting, a device that removes and reuses excess powder adhered after printing is completed.

In Selective Laser Sintering, Binder Jetting, a device that removes and reuses excess powder adhered after printing is completed.

Provided by 3D Solution Center

▲The mechanism to put on the vacuum cleaner

By the way, the powder rate that can be recycled is called the recycling rate The recycle rate is the ratio of how much of the leftover powder that is not used in a Selective Laser Sintering or Binder Jetting method 3D printer can be used for the next printing. and it is a criterion for choosing a product of Selective Laser Sintering. It is usually about 60% to 80%.

The recycle rate is the ratio of how much of the leftover powder that is not used in a Selective Laser Sintering or Binder Jetting method 3D printer can be used for the next printing. and it is a criterion for choosing a product of Selective Laser Sintering. It is usually about 60% to 80%.

We will introduce the features of Selective Laser Sintering.

You don't have to print support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. because the extra powder accumulates at the bottom of the printing object. Therefore, you can print more elaborate and complex 3D objects.

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. because the extra powder accumulates at the bottom of the printing object. Therefore, you can print more elaborate and complex 3D objects.

Made by us

▲The reason why you don’t need support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling..

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling..

Selective Laser Sintering usually uses nylonNylon is a type of synthetic fiber made from petroleum. It has excellent durability and heat resistance and is mainly used as a printing material for powder Selective Laser Sintering. There are various types such as nylon 6, nylon 11, and nylon 12. as a material, but some products can use metal.

Place: 3D Solution Center

▲A metal object printed with Selective Laser Sintering

The nylonNylon is a type of synthetic fiber made from petroleum. It has excellent durability and heat resistance and is mainly used as a printing material for powder Selective Laser Sintering. There are various types such as nylon 6, nylon 11, and nylon 12. usually used as a material with Selective Laser Sintering is very sturdy and you can print sturdy 3D objects.

Selective Laser Sintering printers are usually over 10 million yen, which is expensive for individuals. The target customers are companies.

You have to prepare a nitrogen generator A nitrogen generator is, as the name implies, a device that generates nitrogen. In a powder Selective Laser Sintering, nitrogen is filled inside the printer to avoid dust explosions. to avoid dust explosions triggered by powder for the Selective Laser Sintering printer and fulfill it with nitrogen. In addition, a depowdering station

A nitrogen generator is, as the name implies, a device that generates nitrogen. In a powder Selective Laser Sintering, nitrogen is filled inside the printer to avoid dust explosions. to avoid dust explosions triggered by powder for the Selective Laser Sintering printer and fulfill it with nitrogen. In addition, a depowdering station In Selective Laser Sintering, Binder Jetting, a device that removes and reuses excess powder adhered after printing is completed. or dust extractor

In Selective Laser Sintering, Binder Jetting, a device that removes and reuses excess powder adhered after printing is completed. or dust extractor A dust extractor is a device that collects dust from the air. is also required for you. Therefore, preparing these machines is an obstacle to introduction.

A dust extractor is a device that collects dust from the air. is also required for you. Therefore, preparing these machines is an obstacle to introduction.

Provided by 3D Solution Center

Nitrogen generator

Place: 3D Solution Center

Dust extractor

The printed objects with Selective Laser Sintering become rough surfaces and low resolution because they use powder as a material. Therefore, you have to process the surface smoothly.

Selective Laser Sintering is usually over 10 million yen and is too expensive as a home-use 3D printer.

On the other hand, it can print sturdy objects and some of them can print metal. Therefore, it is expected to print final products The final product is one that is actually sold to the consumers, not a prototype or sample. Functionality and durability are required. for industrial use.

The final product is one that is actually sold to the consumers, not a prototype or sample. Functionality and durability are required. for industrial use.

These are the features of Selective Laser Sintering.

We will show some pictures of Selective Laser Sintering and its printed objects.

Selective Laser Sintering

Provided by 3D Solution Center

The structure of Selective Laser Sintering

Place: 3D Solution Center

A mechanism like a windscreen wiper

Place: 3D Solution Center

A hole for emitting laser

Place: 3D Solution Center

Printed objects with Selective Laser Sintering

Place: 3D Solution Center

Powder (for Binder Jetting)

Place: 3D Solution Center

Cube box that moves the printed object

Place: 3D Solution Center

Depowdering station

Place: 3D Solution Center

The mechanism of depowdering station

Place: 3D Solution Center

The mechanism to put on the vacuum cleaner

Provided by 3D Solution Center

A metal object printed with Selective Laser Sintering

Place: 3D Solution Center

A nitrogen generator

Provided by 3D Solution Center

A dust extractor

Place: 3D Solution Center