MultiJet Printing

MultiJet printing is a method that draws each layer and stacks them by jetting resins out from Inkjet Printhead An inkjet printhead is a movable device in an inkjet printer through which ink is sprayed. and solidifying them with a UV laser. We’ll introduce the feature and printing process of MultiJet Printing on this page.

An inkjet printhead is a movable device in an inkjet printer through which ink is sprayed. and solidifying them with a UV laser. We’ll introduce the feature and printing process of MultiJet Printing on this page.

Table of Contents

The table is the basic information list of MultiJet Printing.

| ISO standards | Material Jetting |

|---|---|

| Aliases | MJP, MJT, PolyJet |

| Cost | Expensive |

| Performance | Very good |

How can we print 3D objects with MultiJet Printing?

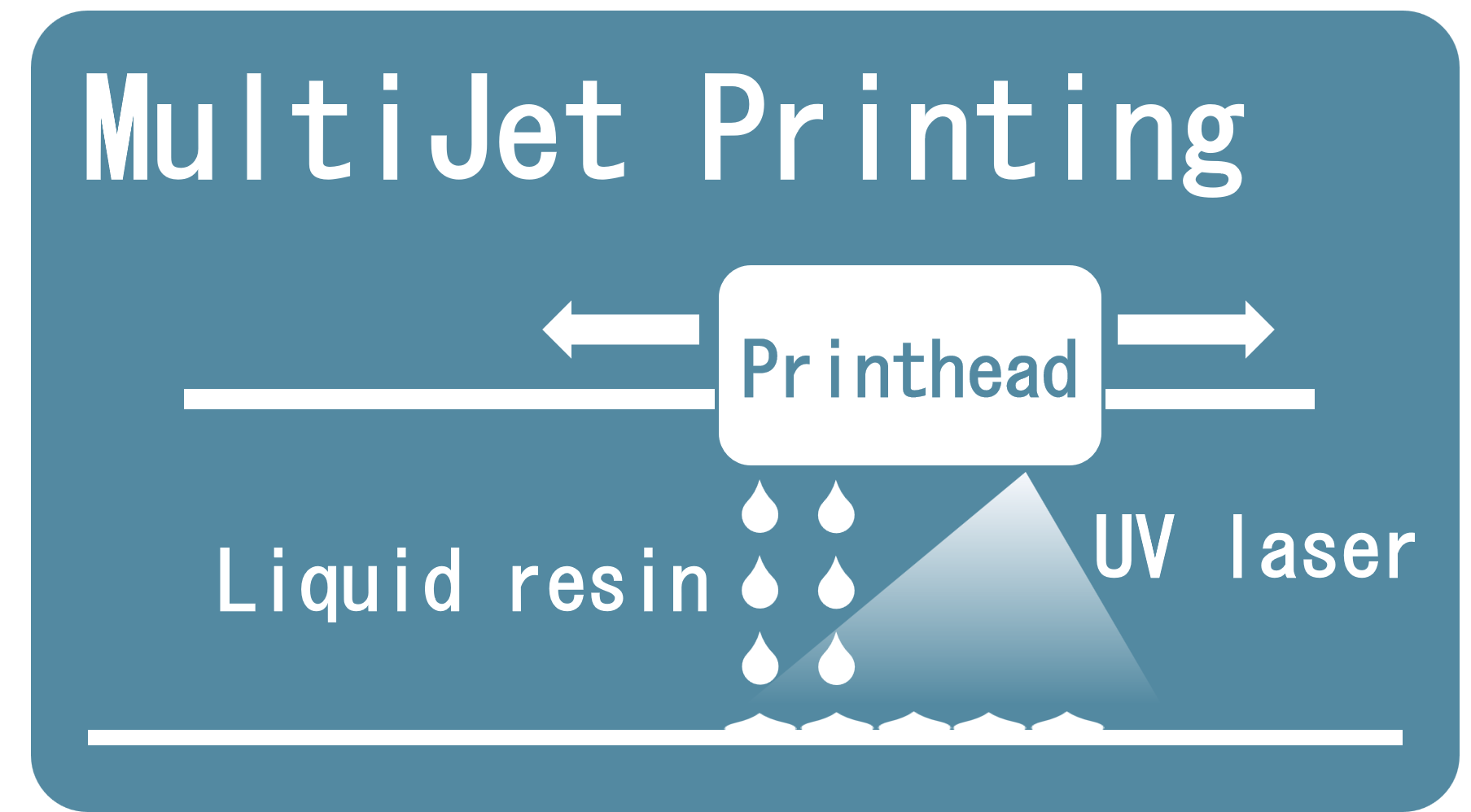

MultiJet Printing is a 3D printing system utilizing the technology of inkjet printers, ordinary printers most of us have. Instead of ink, the printer sprays liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. onto the stage

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. onto the stage A stage is the foundation on which moldings are printed in a 3D printer. from the Inkjet Printhead

A stage is the foundation on which moldings are printed in a 3D printer. from the Inkjet Printhead An inkjet printhead is a movable device in an inkjet printer through which ink is sprayed..

An inkjet printhead is a movable device in an inkjet printer through which ink is sprayed..

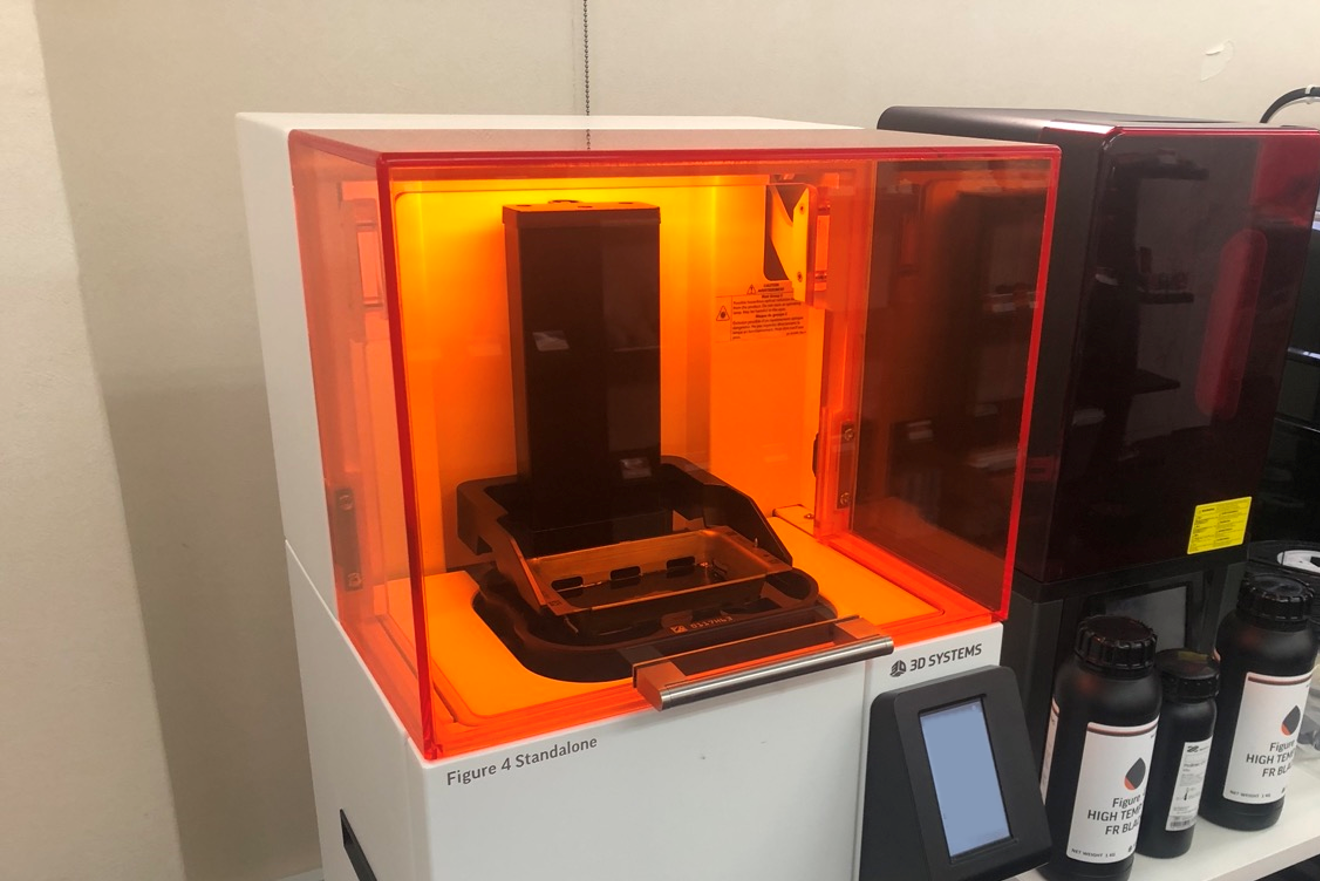

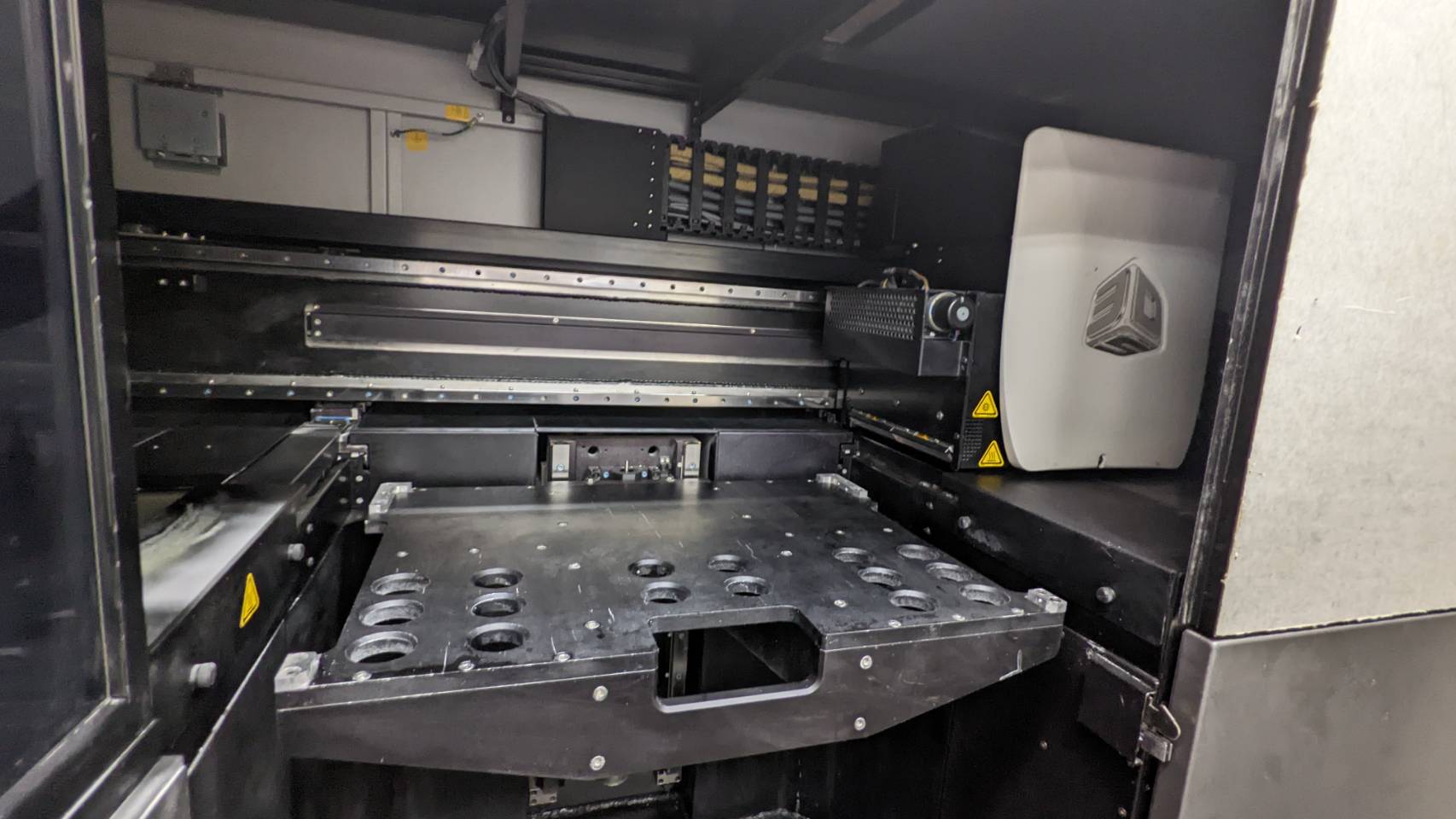

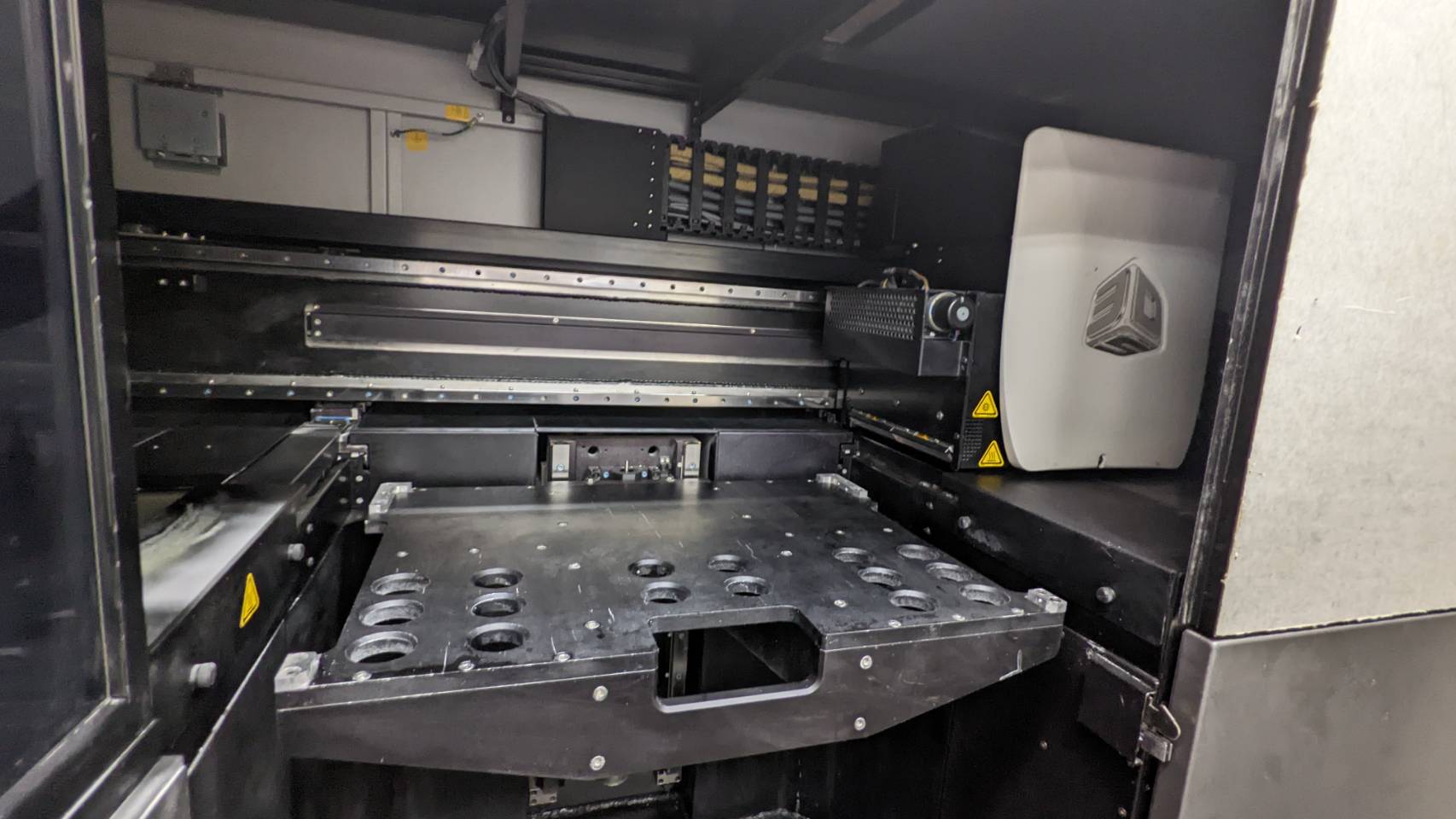

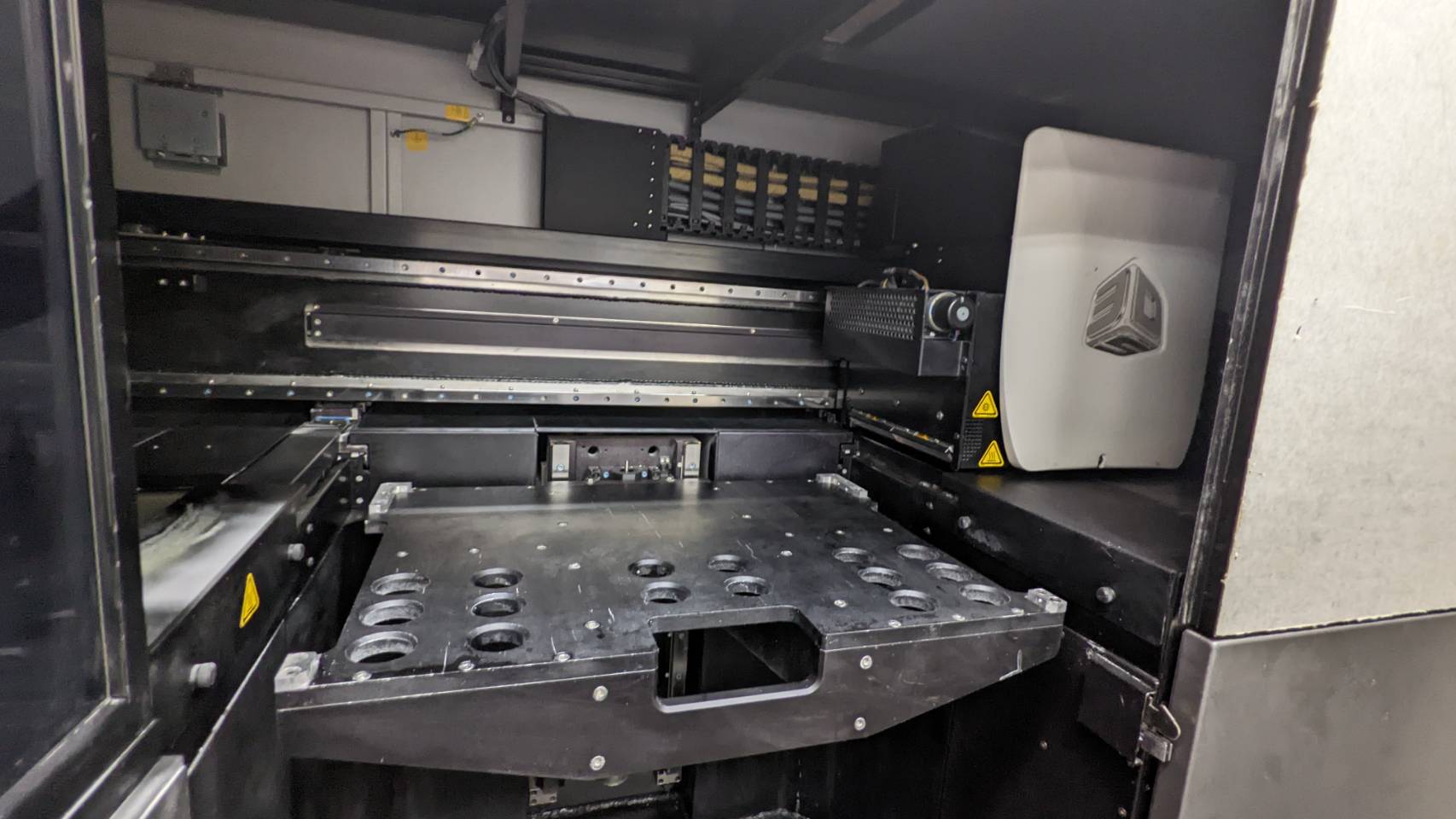

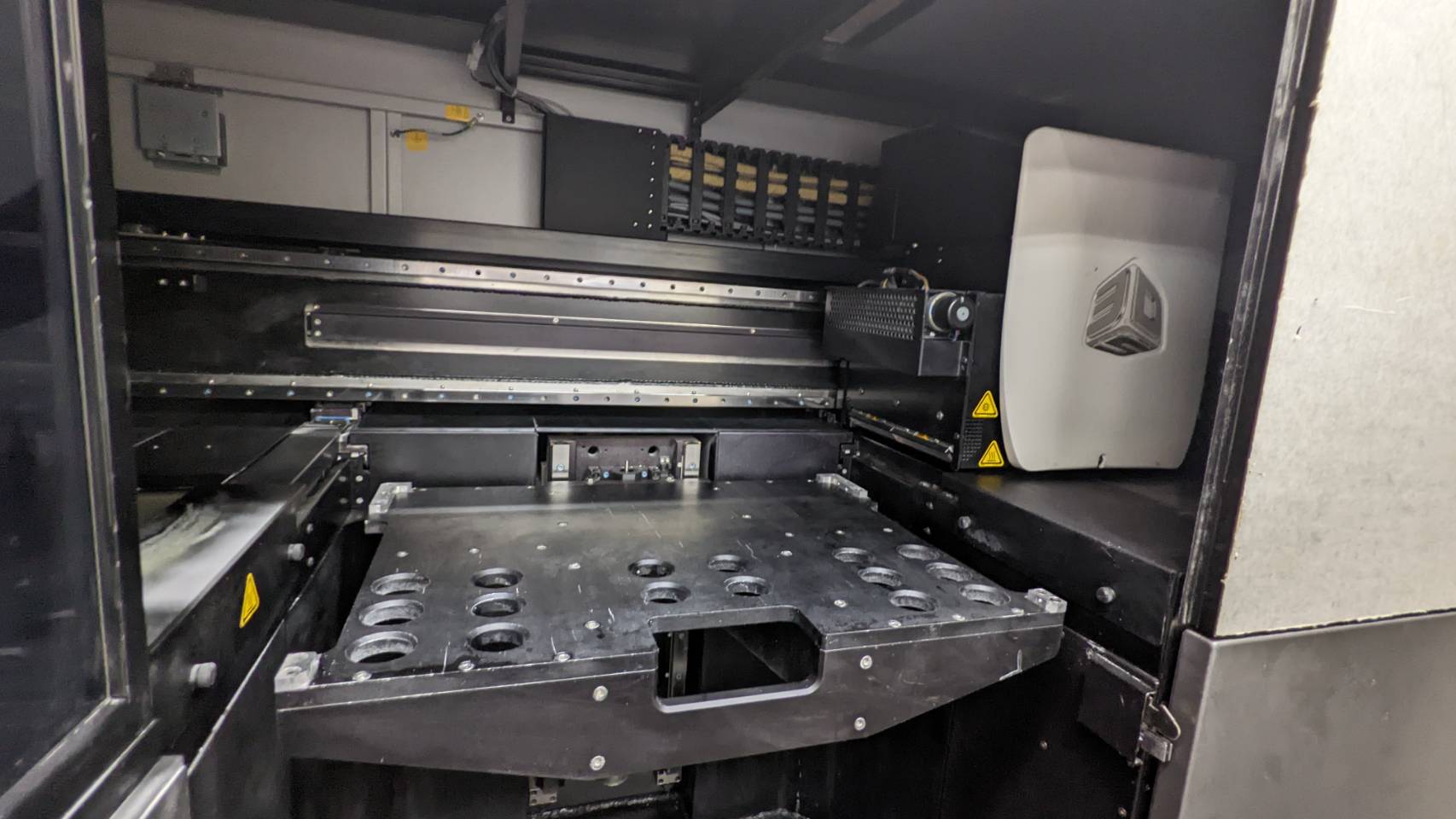

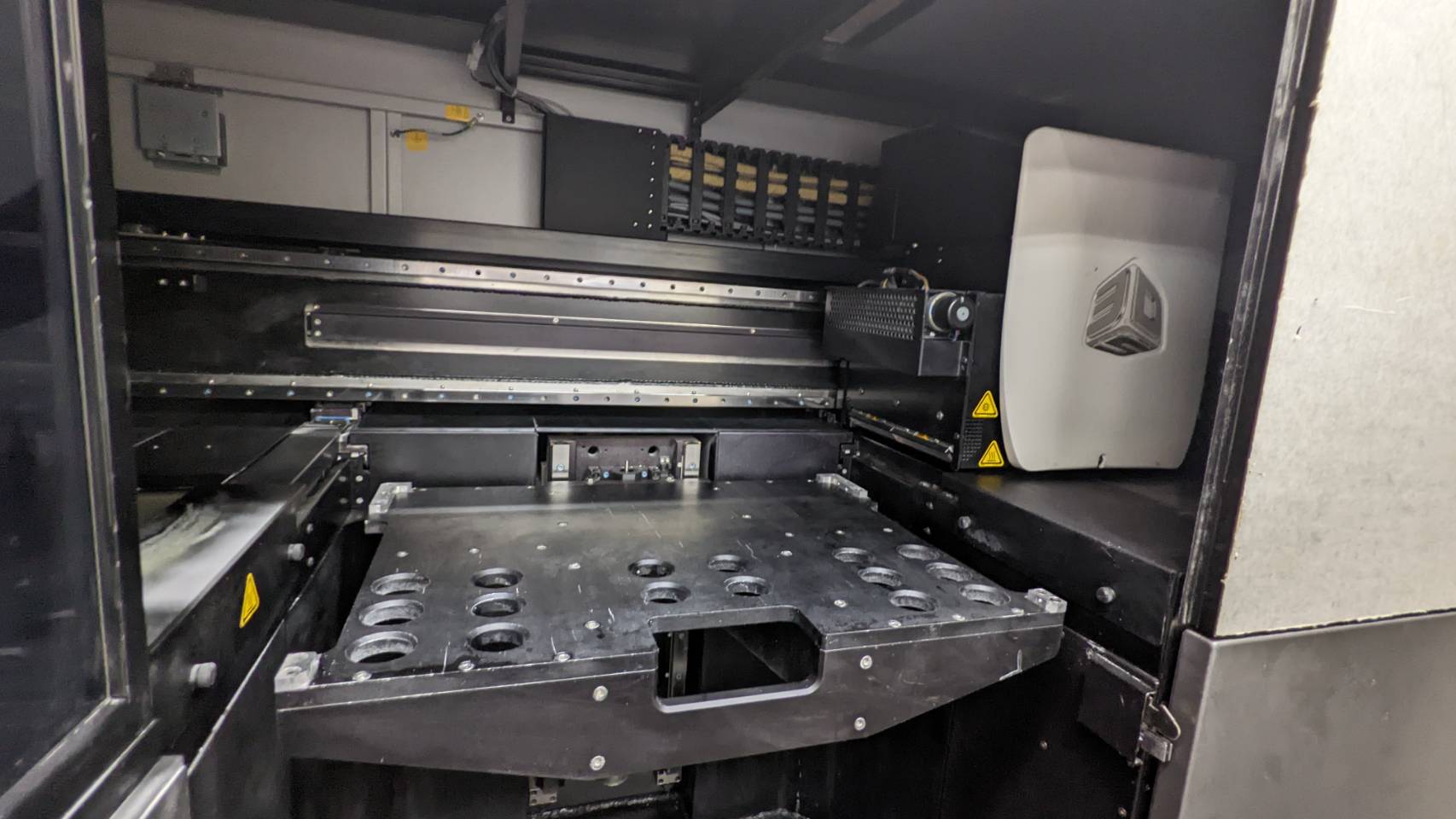

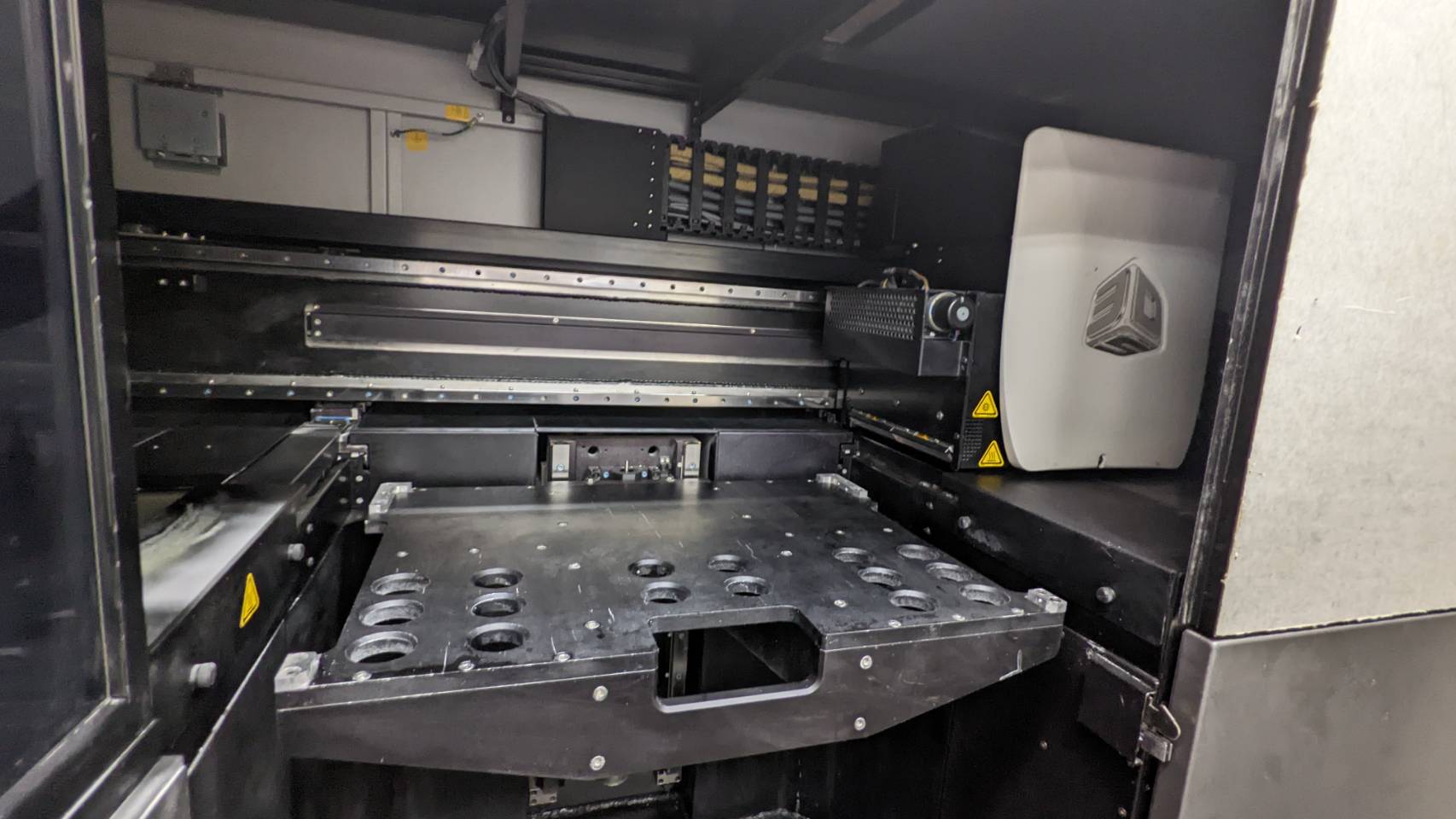

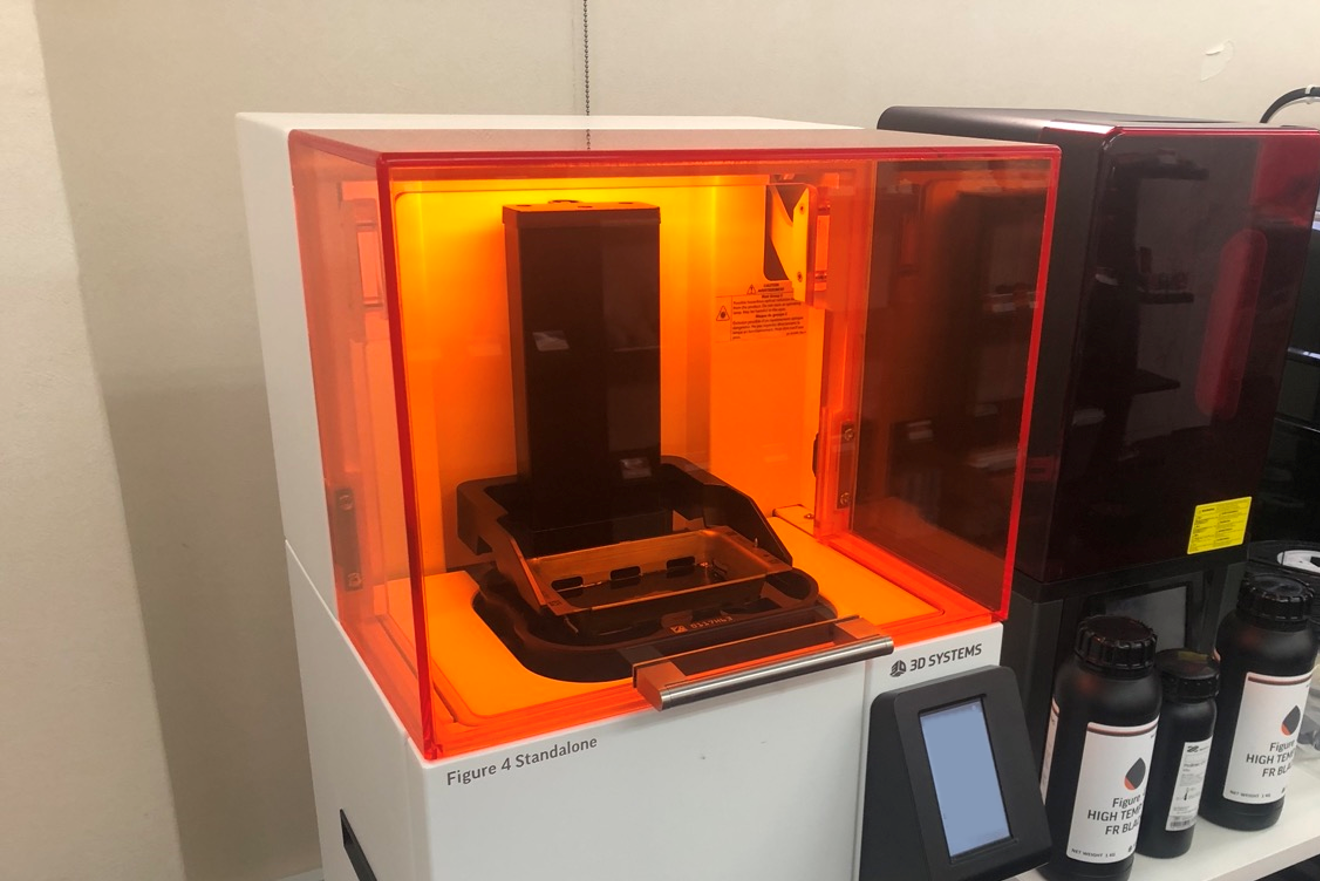

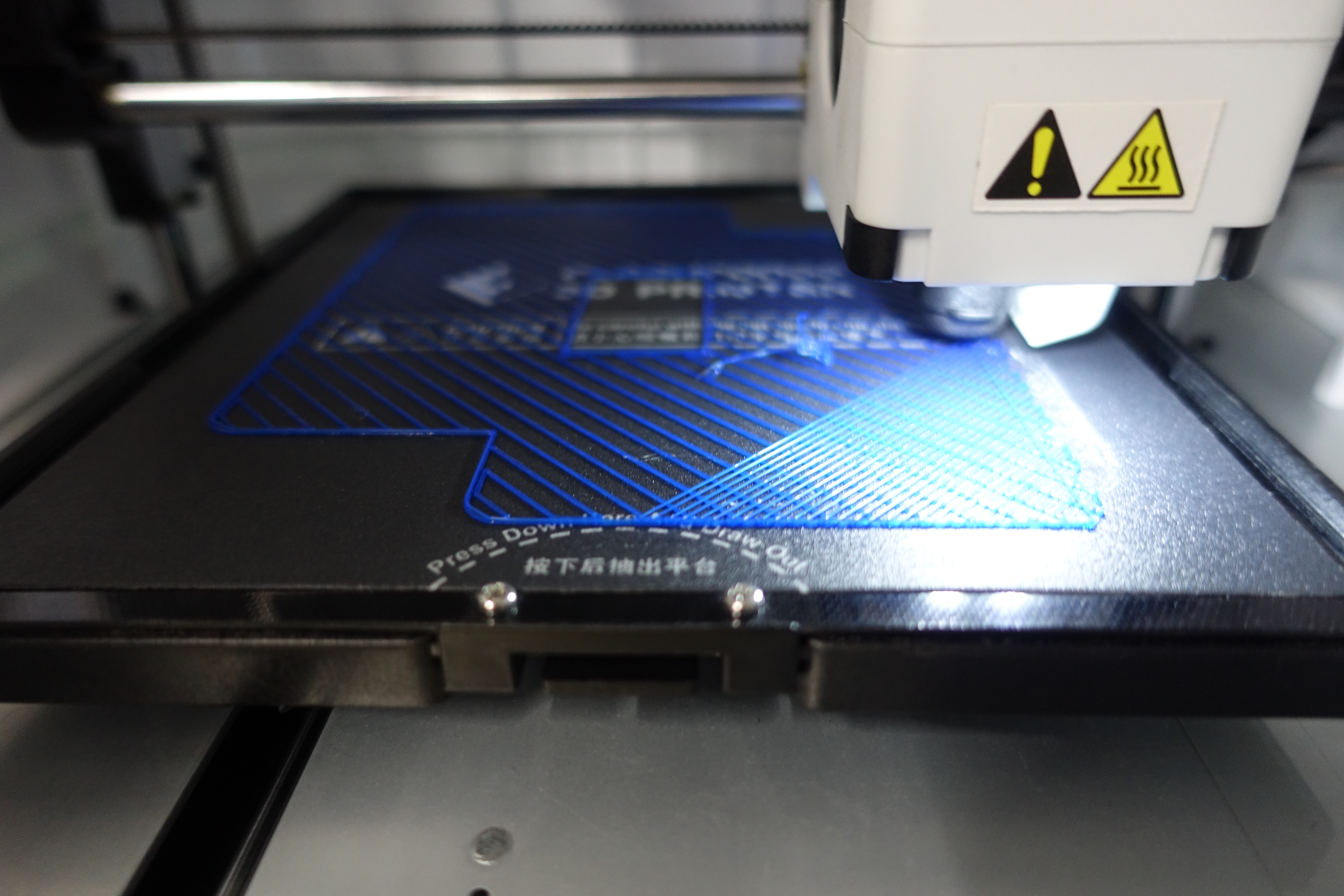

Place: 3D Solution Center

▲Inkjet printhead An inkjet printhead is a movable device in an inkjet printer through which ink is sprayed. and stage

An inkjet printhead is a movable device in an inkjet printer through which ink is sprayed. and stage A stage is the foundation on which moldings are printed in a 3D printer.

A stage is the foundation on which moldings are printed in a 3D printer.

The device draws a layer by jetting liquid resin from the inkjet printhead An inkjet printhead is a movable device in an inkjet printer through which ink is sprayed. and changing the relative position between the stage

An inkjet printhead is a movable device in an inkjet printer through which ink is sprayed. and changing the relative position between the stage A stage is the foundation on which moldings are printed in a 3D printer. and the inkjet printhead

A stage is the foundation on which moldings are printed in a 3D printer. and the inkjet printhead An inkjet printhead is a movable device in an inkjet printer through which ink is sprayed.. A UV laser solidifies jetted liquid resin

An inkjet printhead is a movable device in an inkjet printer through which ink is sprayed.. A UV laser solidifies jetted liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. immediately. The system has both functions of Fused Filament Fabrication

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. immediately. The system has both functions of Fused Filament Fabrication Fused Filament Fabrication is a method that draws each layer and stacks them by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle. and Stereolithography

Fused Filament Fabrication is a method that draws each layer and stacks them by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle. and Stereolithography Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser..

Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser..

Made by us

▲System of MultiJet Printing

The device stacks each formed layer by moving the stage A stage is the foundation on which moldings are printed in a 3D printer. to Z-axis while printing the resin.

A stage is the foundation on which moldings are printed in a 3D printer. to Z-axis while printing the resin.

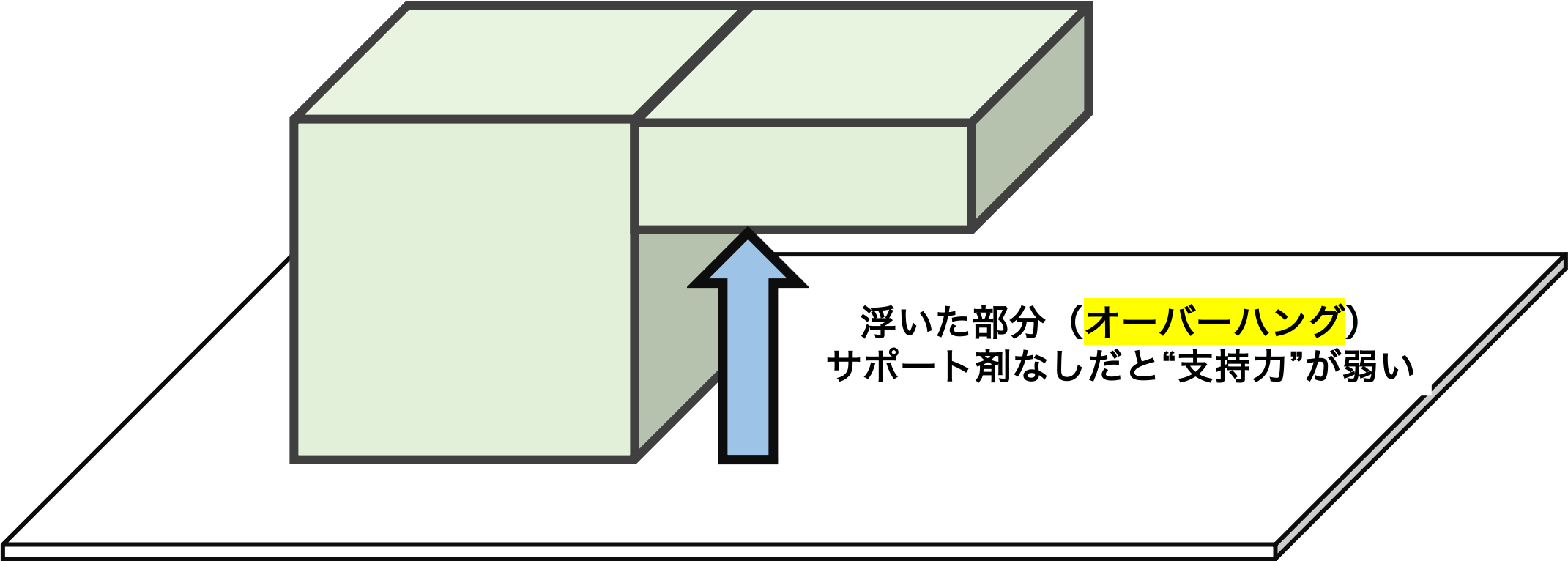

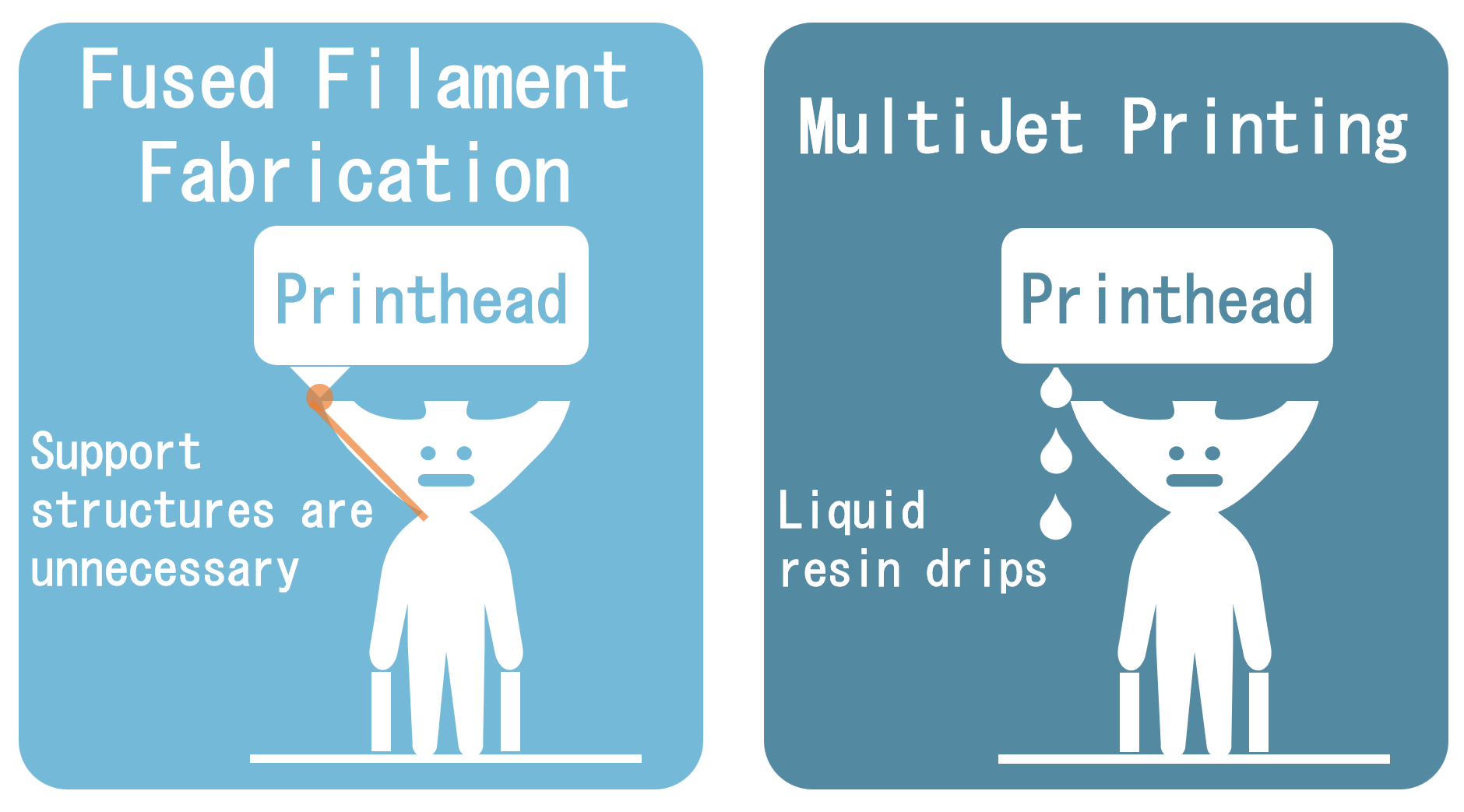

When overhangs An overhangs is an area in a modeling object that is floating in the air without support. Support structures is required when printing moldings. (floating) happen, we make support structures

An overhangs is an area in a modeling object that is floating in the air without support. Support structures is required when printing moldings. (floating) happen, we make support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. for printing. However, we have to use about three times as much support structures

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. for printing. However, we have to use about three times as much support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. as Fused Filament Fabrication

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. as Fused Filament Fabrication Fused Filament Fabrication is a method that draws each layer and stacks them by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle. when stacking at an oblique angle.

Fused Filament Fabrication is a method that draws each layer and stacks them by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle. when stacking at an oblique angle.

Made by us

▲Differences in support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. between Fused Filament Fabrication

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. between Fused Filament Fabrication Fused Filament Fabrication is a method that draws each layer and stacks them by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle. and MultiJet Printing

Fused Filament Fabrication is a method that draws each layer and stacks them by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle. and MultiJet Printing

This is how MultiJet Printing prints 3D objects.

Some products of MultiJet Printing can print with multiple resins. The resin used for support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. and one for objects are different. By doing so, you can easily remove support structures

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. and one for objects are different. By doing so, you can easily remove support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling., and you can produce beautiful objects after removing support structures

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling., and you can produce beautiful objects after removing support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling.. This is an amazing merit.

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling.. This is an amazing merit.

The following picture shows a ball-shaped printed object using a special resin that melts with heat for the support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. only. Immediately after printing, there are a lot of support structures

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. only. Immediately after printing, there are a lot of support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. at the bottom of and inside the ball (on the right side). By heating the ball and melting support structures

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. at the bottom of and inside the ball (on the right side). By heating the ball and melting support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling., we can make a nested ball.

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling., we can make a nested ball.

Place: 3D Solution Center

▲On the right side: objects immediately after printing. On the left side: objects after heating.

This way, you can print interesting 3D objects using a different kind of resin for support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling..

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling..

We will introduce the features of MultiJet Printing.

Using MultiJet Printing, we can print elaborate objects because their layer resolution Layer resolution is the thickness of each layer of the 3D model. The smaller the thickness is, the more accurate the printing will be. is high. In addition, MultiJet Printing doesn't cause warping and intensity differences.

Layer resolution is the thickness of each layer of the 3D model. The smaller the thickness is, the more accurate the printing will be. is high. In addition, MultiJet Printing doesn't cause warping and intensity differences.

Place: 3D Solution Center

▲Picture of an elaborate keyhole printed with MultiJet Printing

Some types of 3D printers can produce objects with multiple resins and create various 3D objects.

Place: 3D Solution Center

▲Picture of a steering wheel printed with dual resin

Some types of 3D printers can produce full-color objects by adding CMYKCMYK refers to the four colors cyan, magenta, yellow, and black. They are used as primary colors to represent full color in subtractive mixing such as printing. ink to liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling..

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling..

MultiJet Printing printers are usually over 5 million yen, which is expensive for individuals. The target customers are companies.

MultiJet Printing needs many support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. to print because all cavities of printing objects require them.

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. to print because all cavities of printing objects require them.

The 3D object sometimes changes its form with direct sunlight because MultiJet Printing uses a liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling., which is solidified with a UV raiser.

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling., which is solidified with a UV raiser.

The acrylic resin, which is mainly used for MultiJet Printing, is weak and breaks if you press it.

MultiJet Printing is usually over 5 million yen and is too expensive as a home-use 3D printer A home-use 3D printer is one intended for personal purchase. Although home-use 3D printers are less precise than industrial-use printers, they are less expensive, with some printers costing less than 50,000 yen..

A home-use 3D printer is one intended for personal purchase. Although home-use 3D printers are less precise than industrial-use printers, they are less expensive, with some printers costing less than 50,000 yen..

MultiJet Printing can produce elaborate, colored (depending on the types of printers) objects with high resolutions, targeting companies or organizations.

These are the features of MultiJet Printing.

We will show some pictures of MultiJet Printing and its printed objects.

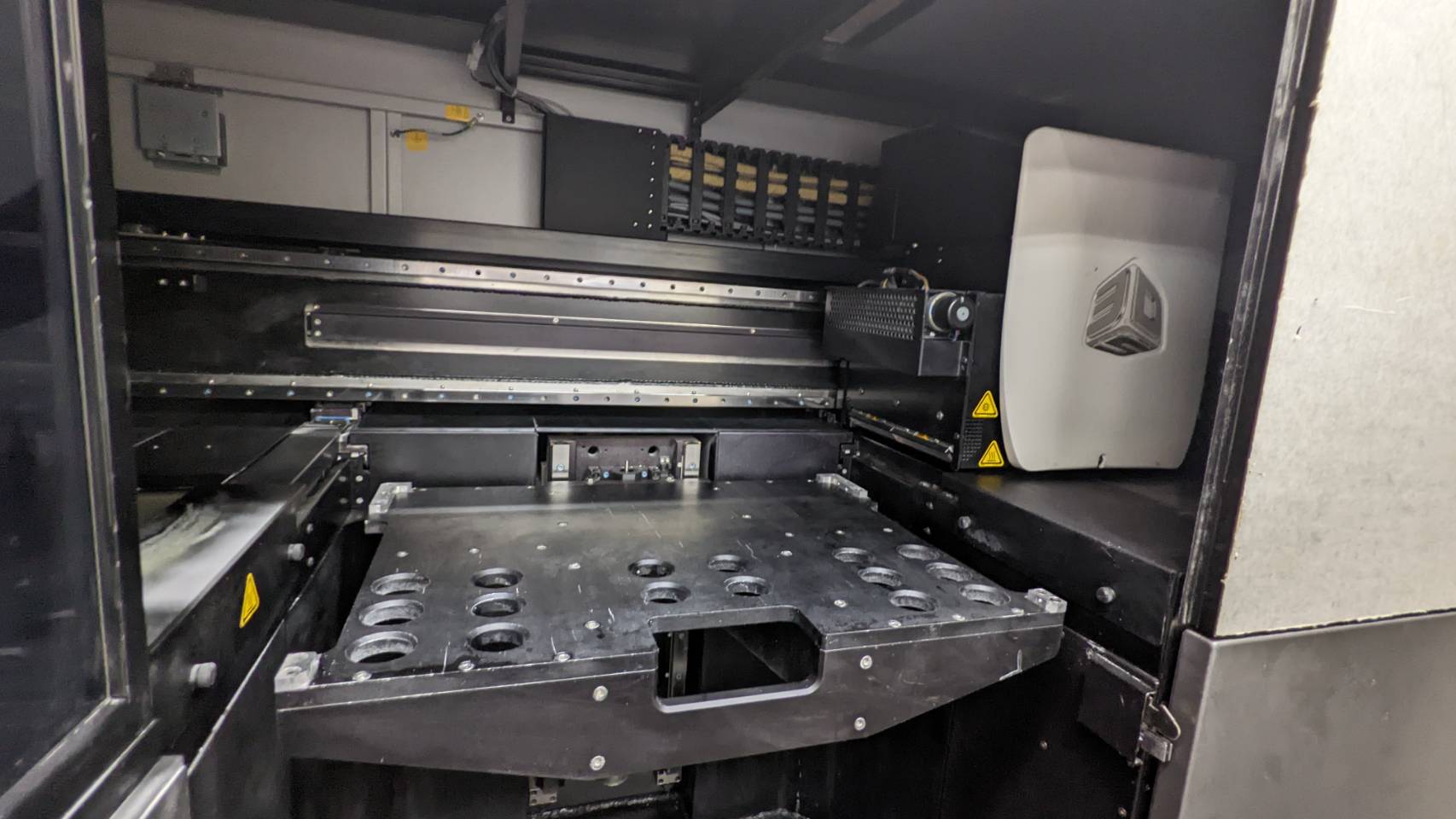

MultiJet Printing

Provided by 3D Solution Center

Inkjet printhead and nozzle

Place: 3D Solution Center

On the right side: objects immediately after printing. On the left side: objects after heating.

Place: 3D Solution Center

Picture of an elaborate keyhole printed with MultiJet Printing

Place: 3D Solution Center

Picture of a steering wheel printed with dual resin

Place: 3D Solution Center