Space

Table of Contents

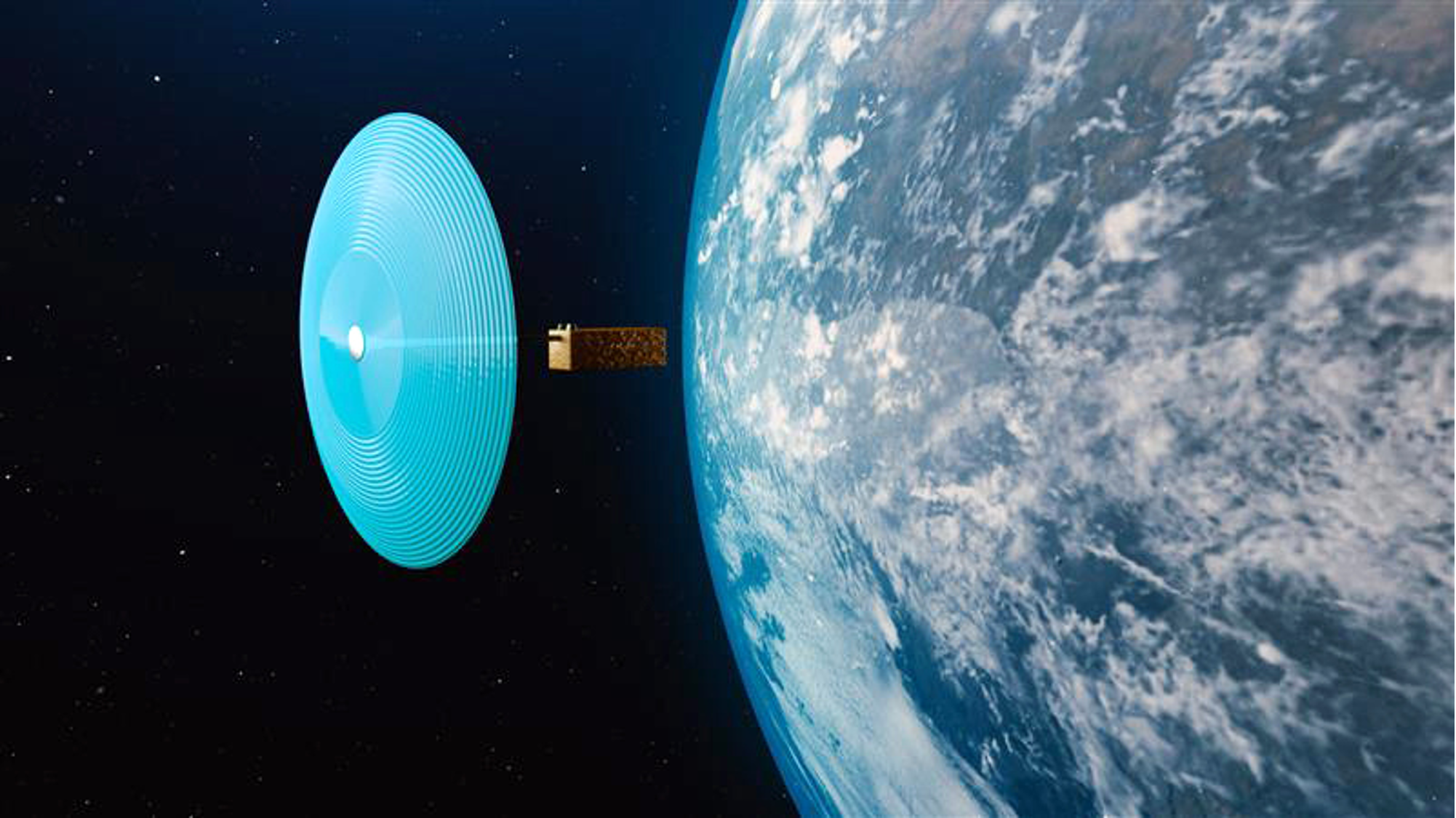

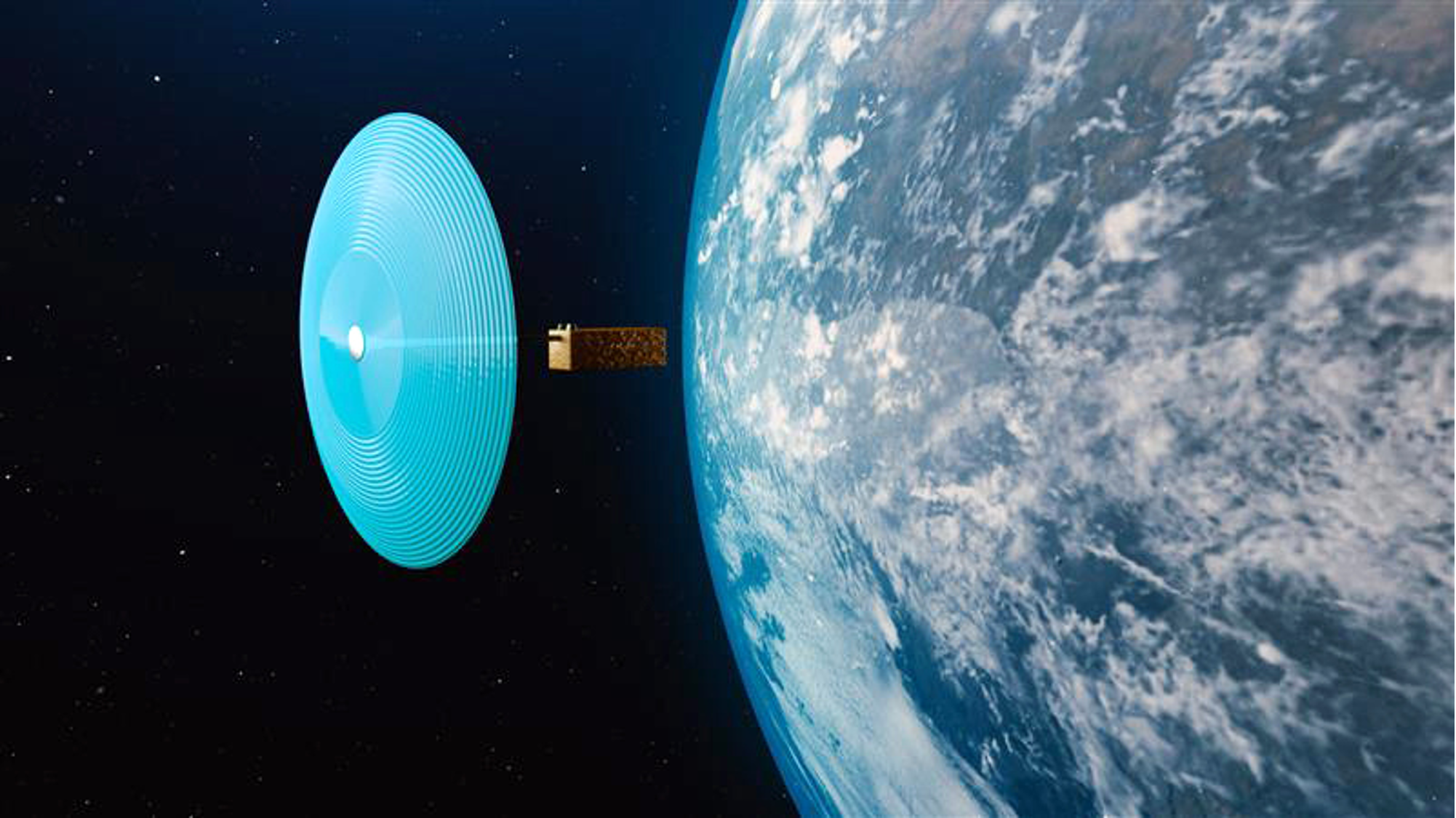

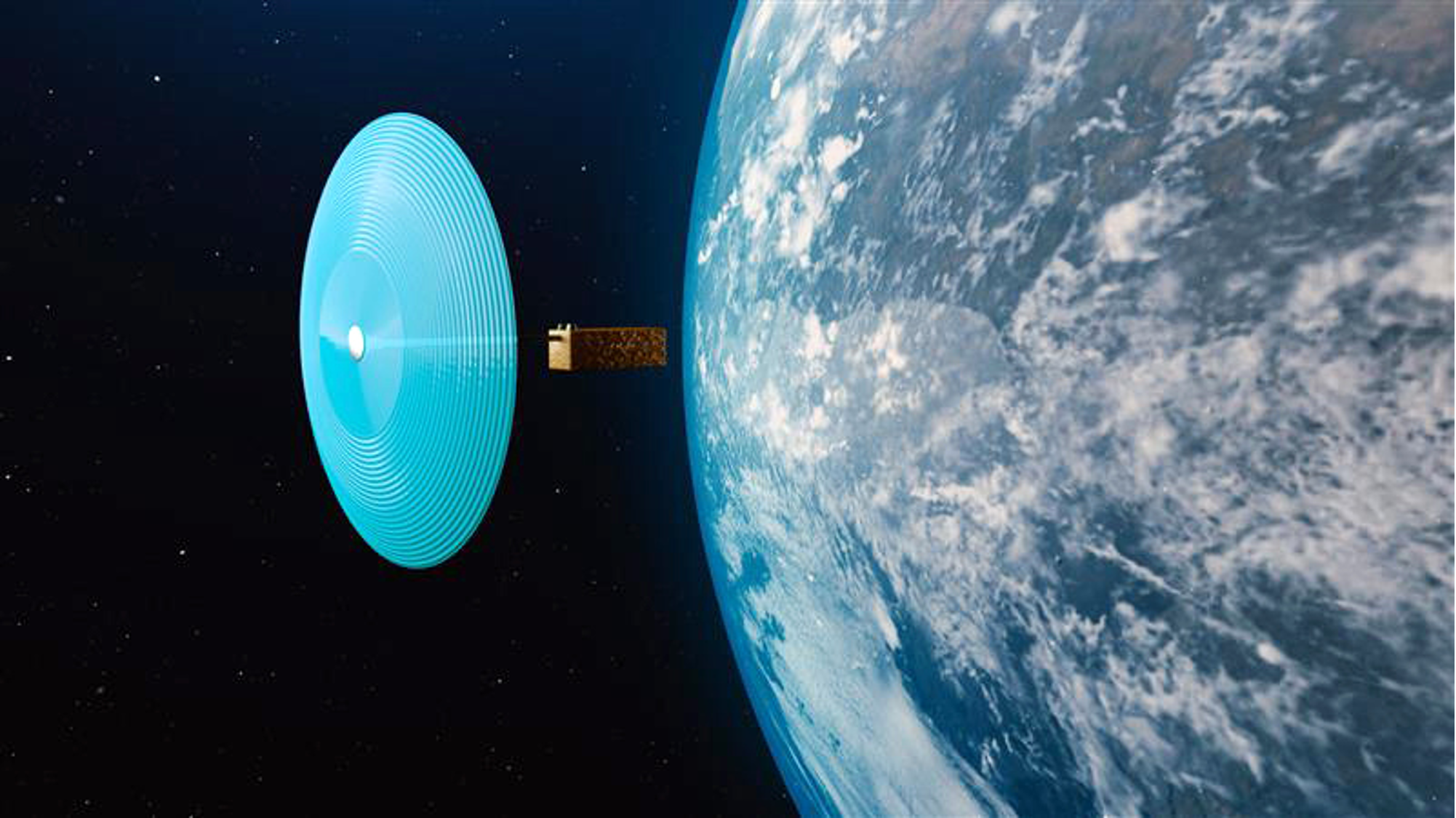

It costs a significant amount of money to send a satellite to space in a conventional way due to the huge sizes of an antenna and a rocket.

It is unnecessary to send antennas to space with a rocket but to send a 3D printer. We can produce antennas with a 3D printer in space. Therefore, we can save money and use the funds to build facilities or make equipment.

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling., which are usually necessary to make objects in space.

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling., which are usually necessary to make objects in space.

Provided by Mitsubishi Electric

▲Structural Chart of The Research

Provided by Mitsubishi Electric

▲MERL in Cambridge, Massachusetts, USA

We asked the following seven questions about Mitsubishi Electric's research and "3D printing in outer space."(August 22th)

Provided by Mitsubishi Electric

▲Appearance of Interview

Please note that the questions and answers presented on this page are the personal opinions of the MERL researchers and do not represent the consensus of Mitsubishi Electric as a whole. We appreciate your understanding of this point.

Q.1

May we ask you to briefly describe the type of project you are working on?

A.1

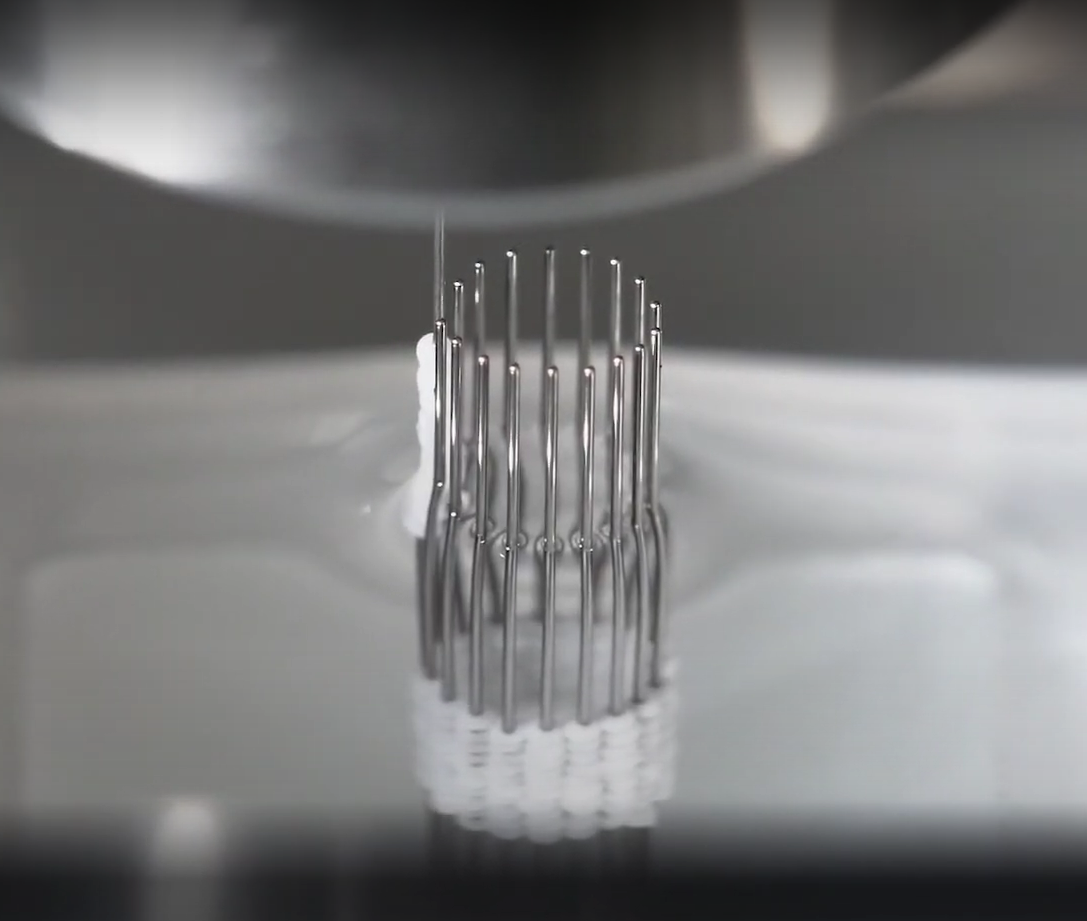

We are working on a research project to build antennas in space. Both of us, Avishai and Bill, are working on the development of resin and a 3D printer.

Q.2

May we ask you to explain how you came up with the idea of undertaking such a project?

A.2

At MERL, we often have brainstorming sessions and discuss quite specialized topics. Avishai, who has a Ph.D. in aerospace engineering, and Bill, an expert in 3D printing and hardware, discussed the new project. That is how this project started.

Q.3

What is the difference between printing on the ground and printing in space?

A.3

The significant difference in space is zero gravity and vacuum. As a result, we cannot do what we normally can on Earth.

We cannot use the normal resin we usually use on Earth. Also, there is no way to solidify resin in space.

We need to make everything light for launching a rocket. We make solar panels thinner to make them light.

Q.4

I read that support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. are not required. What kind of technology do you use to make this possible?

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. are not required. What kind of technology do you use to make this possible?

A.4

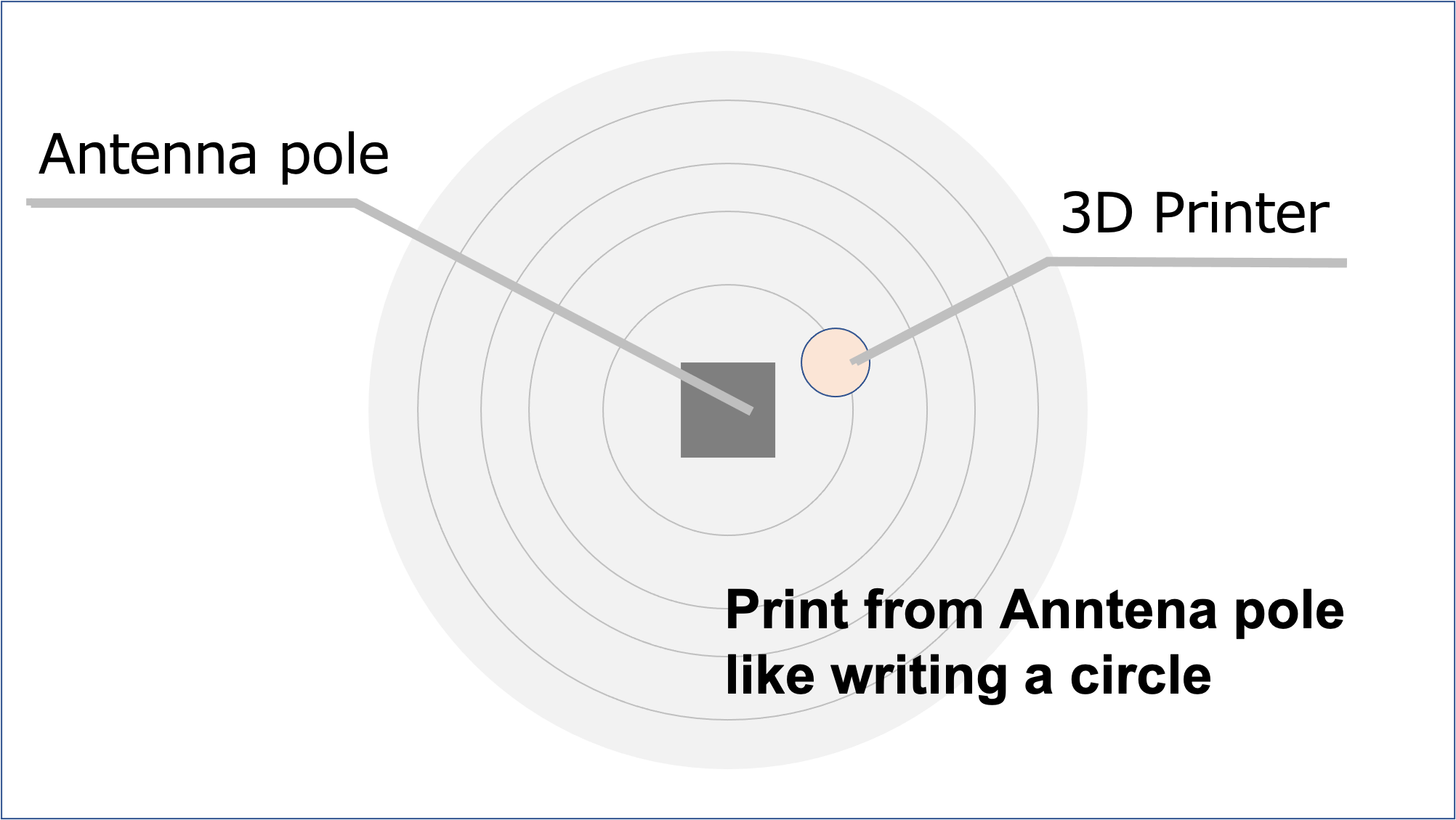

In space, we make objects from the Anntena pole and use liquid resin. So, support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. are not necessary.

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. are not necessary.

Made by us

Provided by Mitsubishi Electric

▲Structural Chart of The Research

The essential thing in space printing is the amount and timing of printing. We use a liquid resin that hardens in the sun's ultraviolet rays when printing the antenna. The amount and timing of the output are important. If the amount of resin is too large, it may not harden into the desired shape, and if the timing is wrong, it may harden into an odd shape.

You can easily understand this phenomenon by imagining a dentist using a tool that hardens the resin in the cavity with light.

Q.5

The first thing that comes to mind is a "fast 3D printer. Even if it takes a few hours now, it will eventually be able to mass produce quickly and revolutionize the industrial world.

A.5

The first thing that comes to mind is a "fast 3D printer".

Even if it takes a few hours now, it will eventually be able to mass produce in a short time and revolutionize the industrial world.

We imagine we can obtain materials for 3D printing in space in the future. It costs a lot to send materials to space from Earth. Therefore, we assume we can have materials from space debris for 3D printing.

Q.6

What were some of the obstacles you encountered during the development process?

A.6

Our obstacles are two things now.

1. We overwhelmingly lack the knowledge.

2. Scientific Results Discrepancies Scientific.

The time it takes for the liquid resin to solidify is different from the scientific findings. However, we enjoy the difficulties and solving these issues.

Q.7

What do you envision as the ideal image of "space" x "3D printer" in the end?

A.7

The technology we are inventing will enable us to observe climate change happening in each region in detail in a timely manner. This is our goal.