Tour of 3D Printers

We visited IGUAZU 3D Solution Center which exhibited various kinds of 3D printers and learned about those 3D printers.

Table of Contents

IGUAZU 3D Solution Center is a showroom where XYZ PRINTING and 3D Systems 3D printers are displayed.

There are many kinds of 3D printers sold by both manufacturers and some of their prices are over 10 million yen.

Place: 3D Solution Center

▲The Exterior view of the IGUAZU 3D Solution Center

In researching the various types of 3D printers, we decided to visit the site because we wanted to see an industrial 3D printer Industrial 3D printer is one that is actually used by companies as prototypes or final product printing machines. Industrial 3D printers have better printing accuracy than home-use printers, and some of them are priced over 10 million yen. that would actually be used in a company.

Industrial 3D printer is one that is actually used by companies as prototypes or final product printing machines. Industrial 3D printers have better printing accuracy than home-use printers, and some of them are priced over 10 million yen. that would actually be used in a company.

Our goal is to see a wide variety of 3D printers and their printed materials up close and learn about their features and mechanisms.

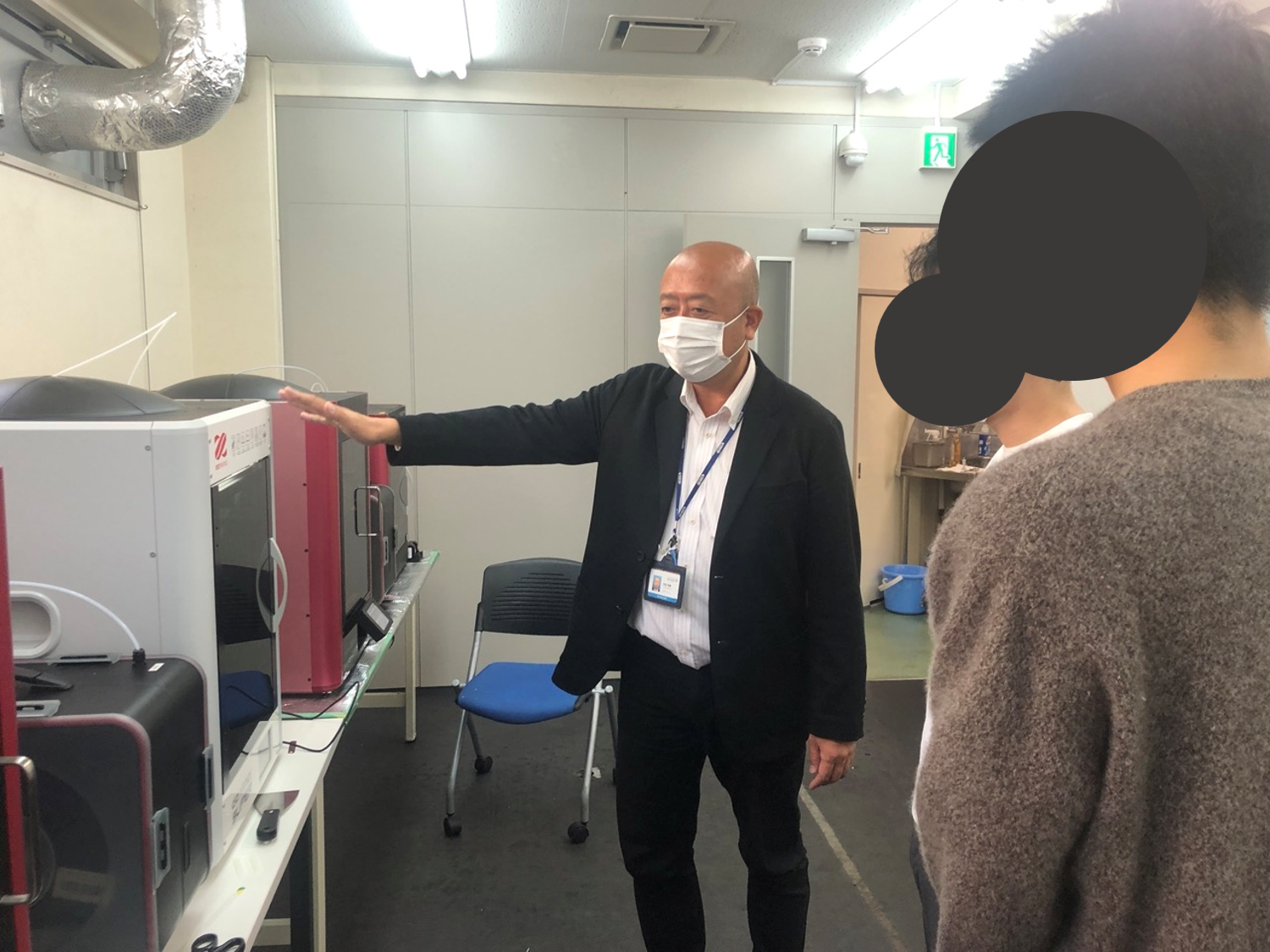

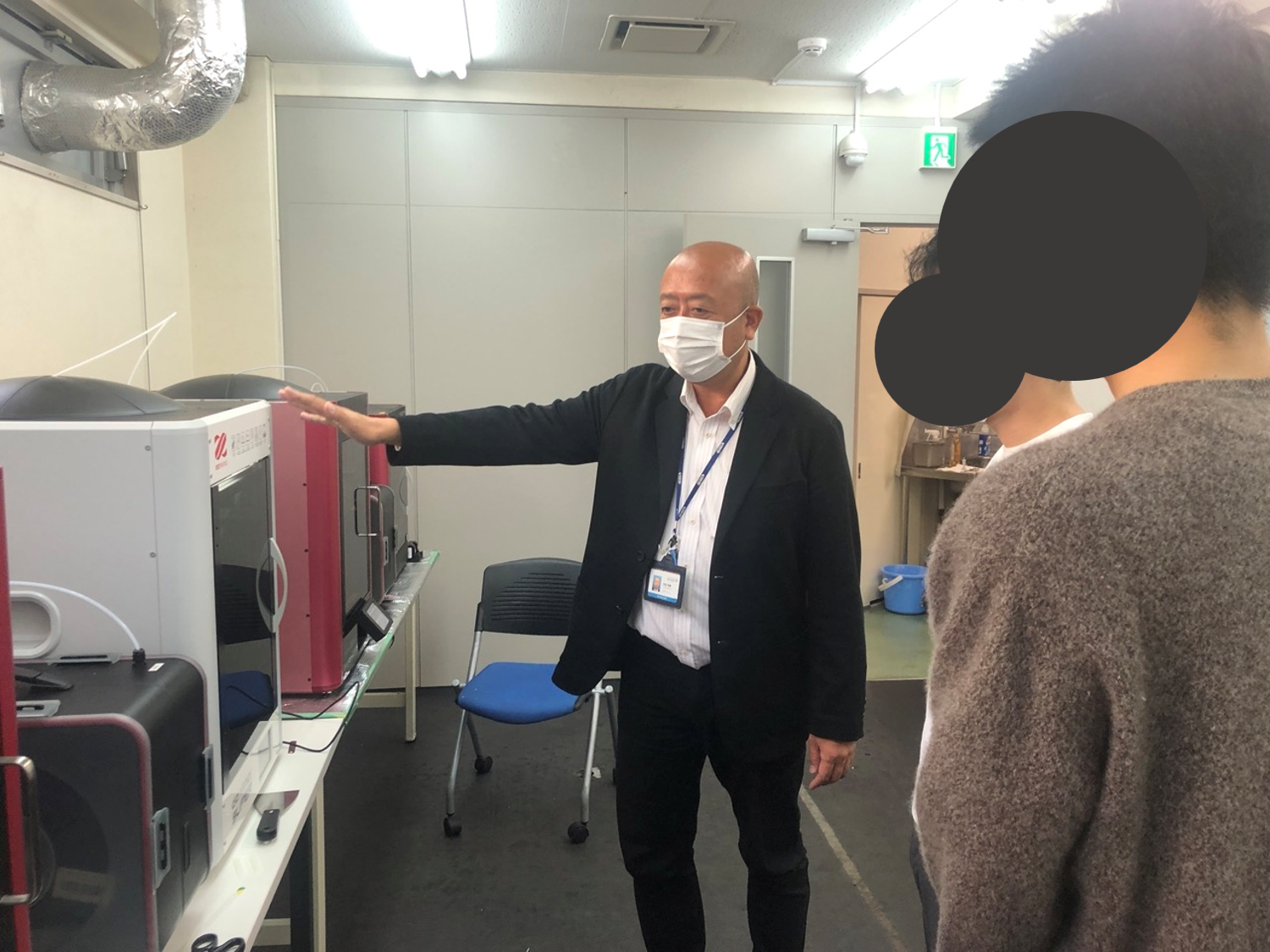

▲Picture of inside the facility

Place: 3D Solution Center

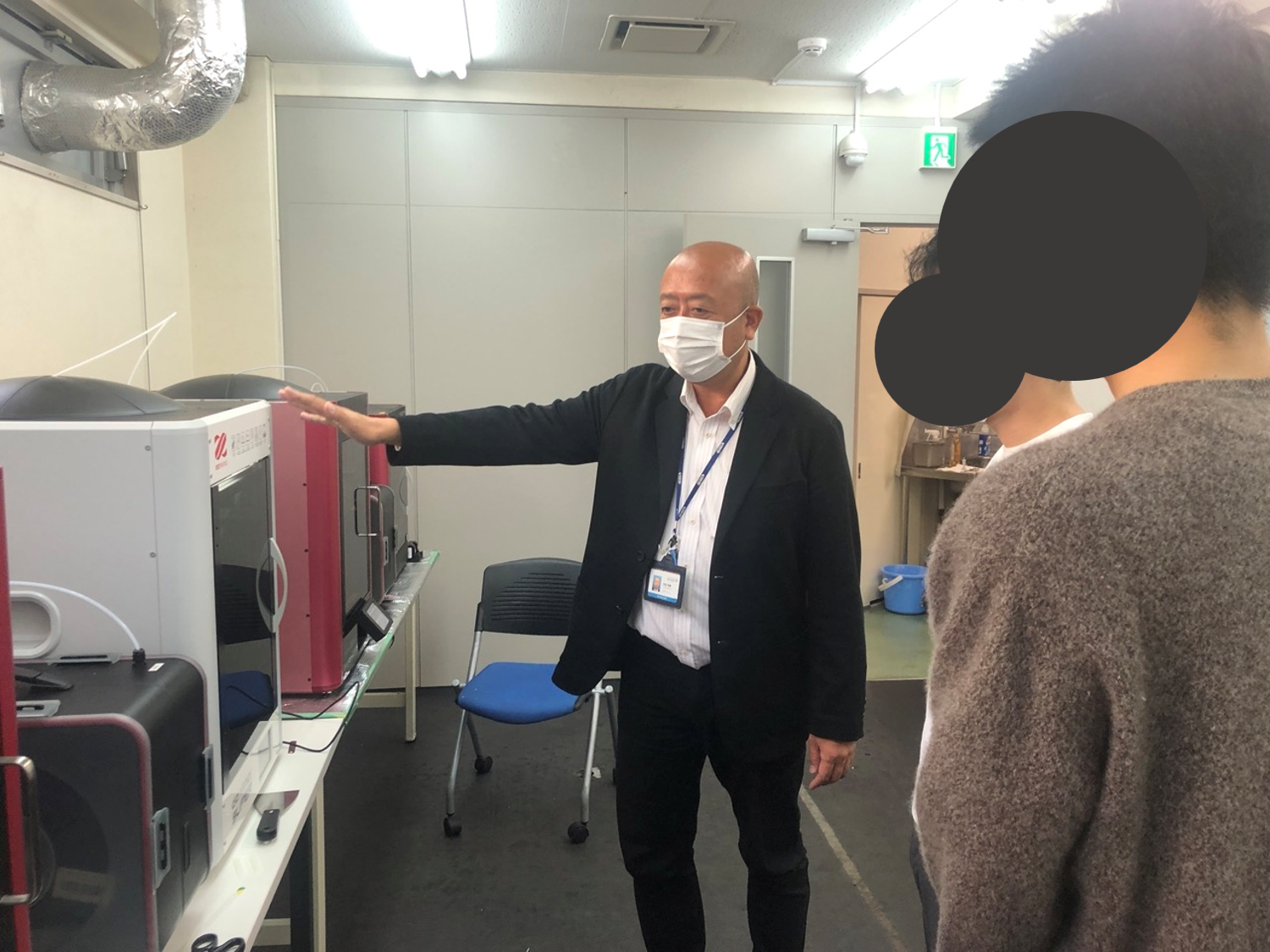

Mr. Machida, IGUAZU 3D Solution Center, introduced 3D printers and gave us a tour of the facility. (December 4th, 2022)

▲Our team members receiving an explanation

Place: 3D Solution Center

First, in the conference room on the third floor, we were given a briefing on the IGUAZU 3D Solution Center and the 3D printers sold by XYZ PRINTING.

IGUAZU is the number one distributor in Japan for two manufacturers, XYZ PRINTING and 3D Systems.

XYZ PRINTING is a Taiwan-based manufacturer mainly engaged in contract manufacturing of 3D printers. Many 3D printer manufacturers come from venture companies, but XYZ PRINTING is a very rare case in which a major company manufactures and sells 3D printers.

On the other hand, 3D Systems is an American venture company originally started by a single engineer. It is known as the first company in the world to commercialize 3D printers.

XYZ PRINTING is selling the " da Vinci " series of 3D printers. The” da Vinci” series was originally branded for personal use, but in 2017, the company launched a line of industrial 3D printers Industrial 3D printer is one that is actually used by companies as prototypes or final product printing machines. Industrial 3D printers have better printing accuracy than home-use printers, and some of them are priced over 10 million yen..

Industrial 3D printer is one that is actually used by companies as prototypes or final product printing machines. Industrial 3D printers have better printing accuracy than home-use printers, and some of them are priced over 10 million yen..

They sell the "PartPro" as a 3D printer for prototype printing for companies and the "MfgPro" for final products The final product is one that is actually sold to the consumers, not a prototype or sample. Functionality and durability are required. printing.

The final product is one that is actually sold to the consumers, not a prototype or sample. Functionality and durability are required. printing.

All part creation and assembly lines are performed by companies within the same group, which means less outsourcing and the price of the unit tends to be lower.

The Fused Filament Fabrication Fused Filament Fabrication is a method that draws each layer and stacks them by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle. is the most widely used type in the world. However, when it comes to industrial use, Stereolithography

Fused Filament Fabrication is a method that draws each layer and stacks them by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle. is the most widely used type in the world. However, when it comes to industrial use, Stereolithography Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser., MultiJet Printing

Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser., MultiJet Printing MultiJet Printing is a method that draws each layer and stacks it by jetting resin from inkjet head and are solidified them with a UV laser., and Selective Laser Sintering

MultiJet Printing is a method that draws each layer and stacks it by jetting resin from inkjet head and are solidified them with a UV laser., and Selective Laser Sintering Selective Laser Sintering is a method that draws each layer by emitting a laser to the flattened powder and solidifying them., which are capable of reproducing precise and curved surfaces, are widely used.

Selective Laser Sintering is a method that draws each layer by emitting a laser to the flattened powder and solidifying them., which are capable of reproducing precise and curved surfaces, are widely used.

The Stereolithography method Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser. is often used to fabricate prototypes, such as to check the appearance of a product or to check its reaction, allowing various ideas to be tried out in a short development period.

Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser. is often used to fabricate prototypes, such as to check the appearance of a product or to check its reaction, allowing various ideas to be tried out in a short development period.

Place: 3D Solution Center

On the other hand, Selective Laser Sintering Selective Laser Sintering is a method that draws each layer by emitting a laser to the flattened powder and solidifying them. is used for printing final products

Selective Laser Sintering is a method that draws each layer by emitting a laser to the flattened powder and solidifying them. is used for printing final products The final product is one that is actually sold to the consumers, not a prototype or sample. Functionality and durability are required. such as a jigA jig is an auxiliary tool used to process a part. Increasingly, 3D printers are being used for production..

The final product is one that is actually sold to the consumers, not a prototype or sample. Functionality and durability are required. such as a jigA jig is an auxiliary tool used to process a part. Increasingly, 3D printers are being used for production..

Provided by 3D Solution Center

Ten years ago, most customers used 3D printers to make prototypes. However, in the past few years, about half of their customers have told them that the customers want to use their 3D printers to print final products The final product is one that is actually sold to the consumers, not a prototype or sample. Functionality and durability are required..

The final product is one that is actually sold to the consumers, not a prototype or sample. Functionality and durability are required..

Place: 3D Solution Center

More recently, some customers want to use 3D printers to print mass-produced parts.

Lightness is also important in fields such as airplanes and aerospace. With ordinary subtractive manufacturingSubtractive manufacturing is a processing method that removes unnecessary portions from existing materials, as opposed to a 3D printer that builds models from scratch., it is not easy to hollow out the inside of a solid object, but with a 3D printer, this can be easily achieved.

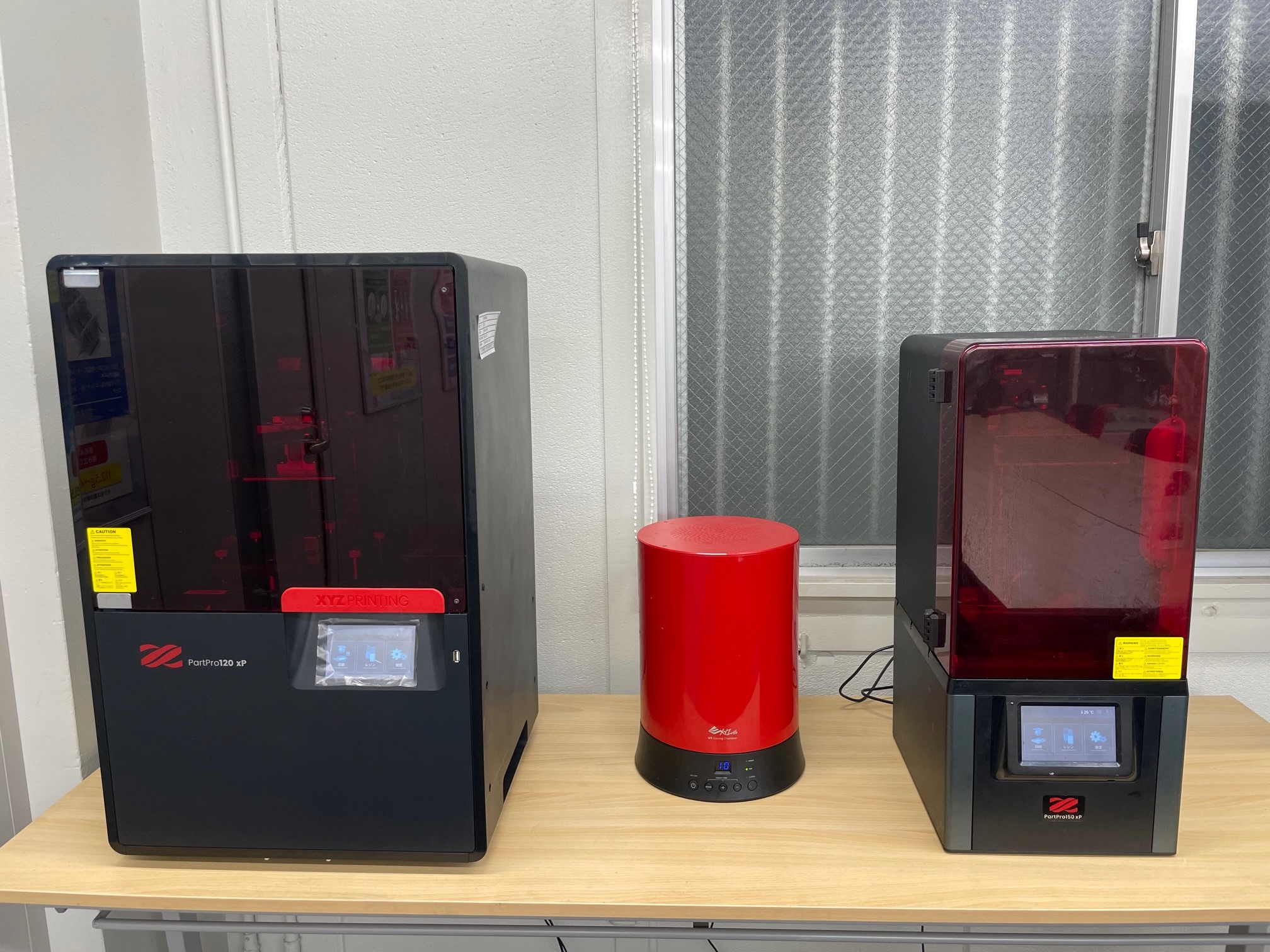

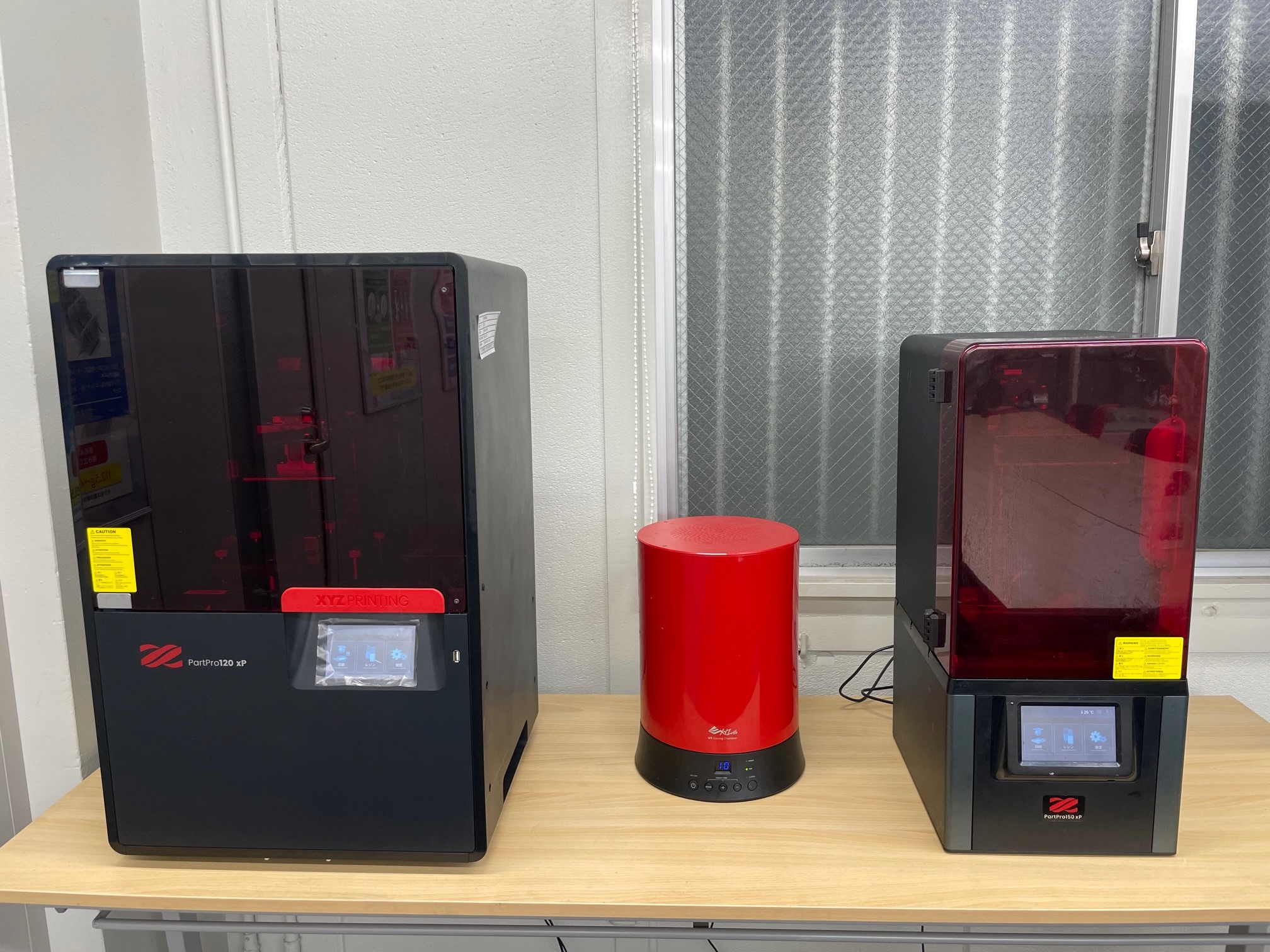

There are exhibits of Stereolithography Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser. and 3D objects printed with 3D printers on the 3rd floor.

Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser. and 3D objects printed with 3D printers on the 3rd floor.

Stereolithography Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser. is a method that creates a cross-sectional shape by irradiating UV light onto liquid resin

Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser. is a method that creates a cross-sectional shape by irradiating UV light onto liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. to cure the resin, and then laminating it. It has the longest history of all 3D printer methods and is characterized by its smooth surface finish.

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. to cure the resin, and then laminating it. It has the longest history of all 3D printer methods and is characterized by its smooth surface finish.

Provided by 3D Solution Center

▲From left to right, are PartPro120 xP and PartPro150 xP. (Manufactured by XYZ PRINTING)

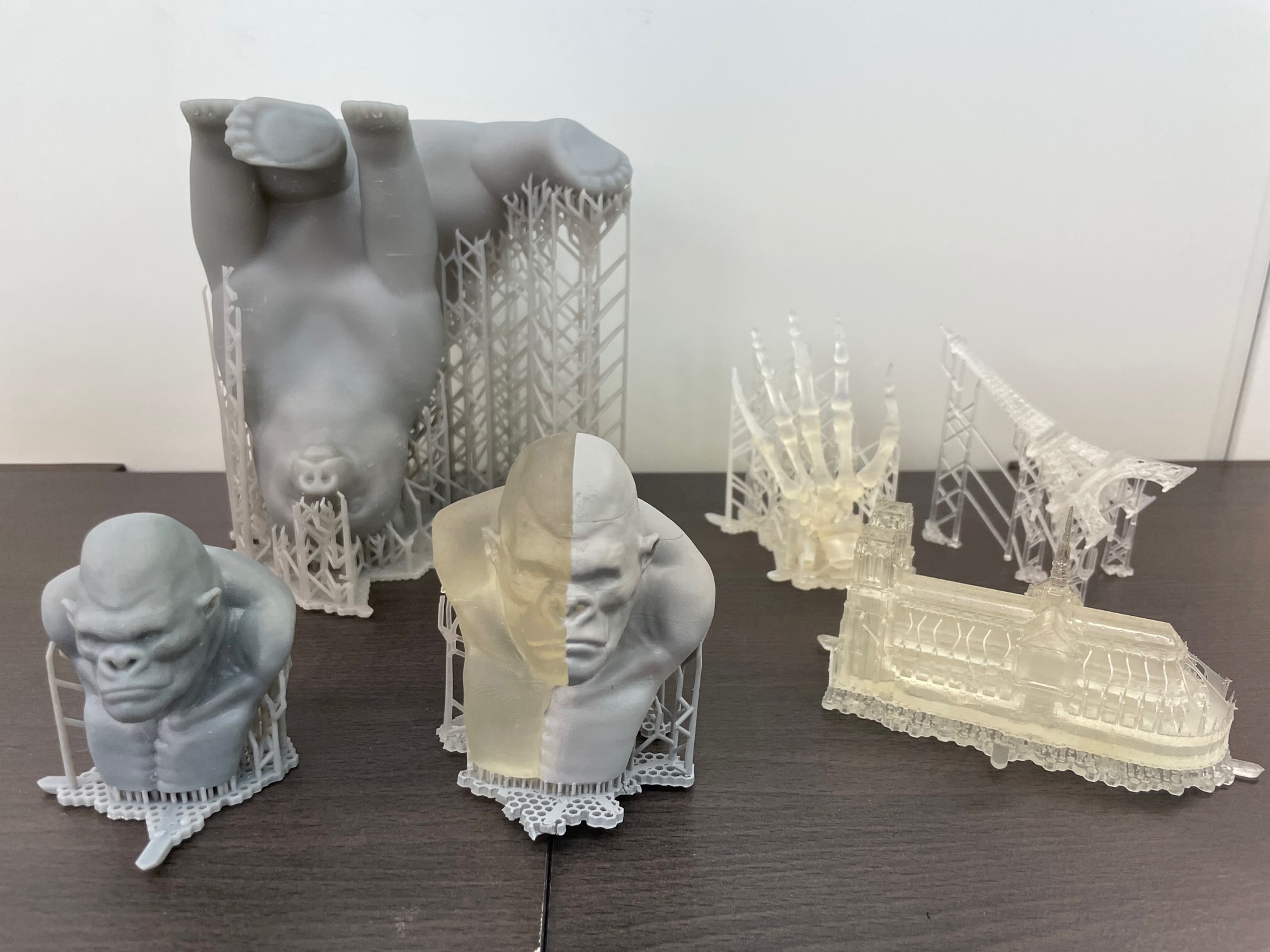

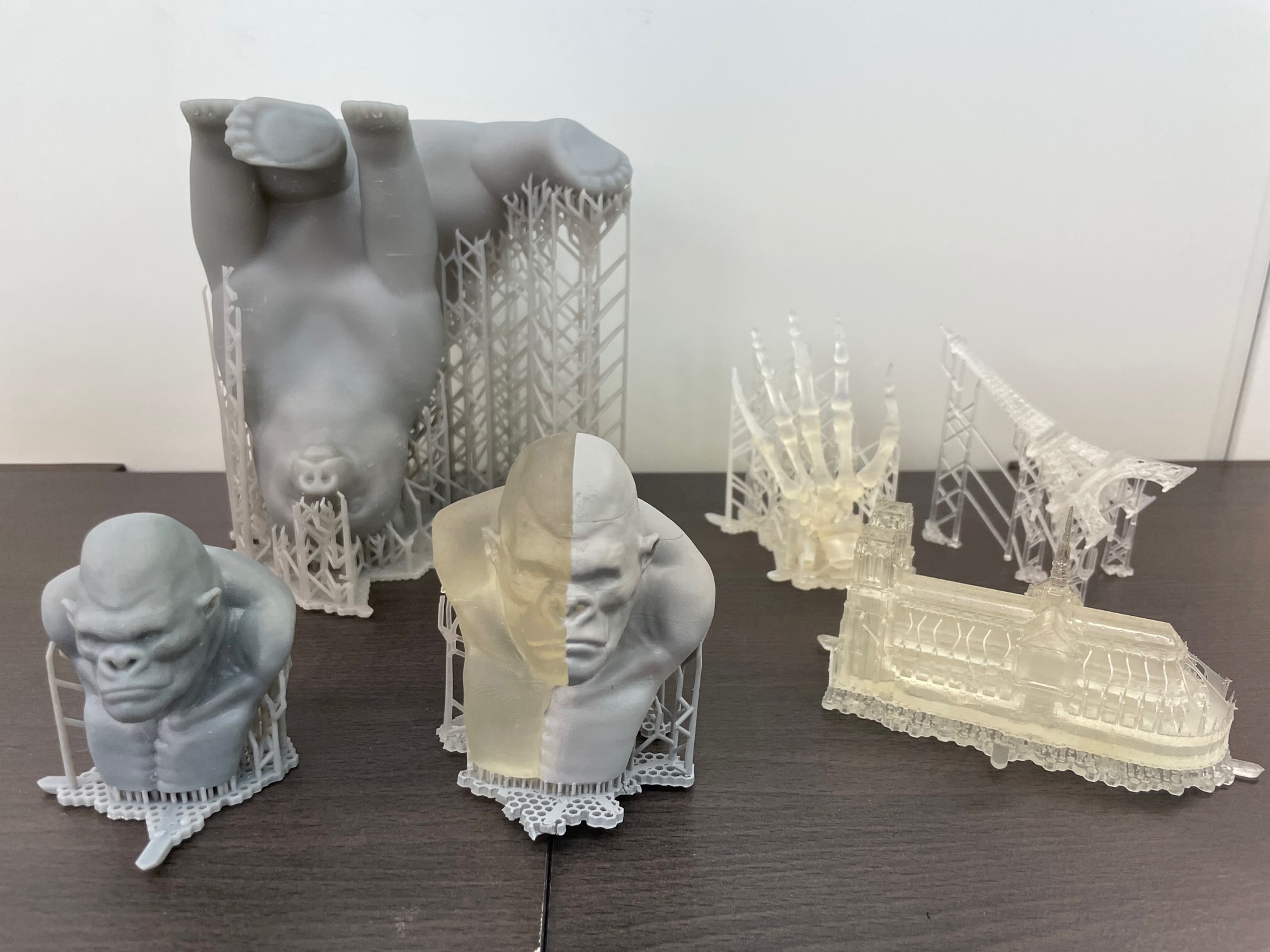

▲The printed objects with Stereolithography Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser.

Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser.

Provided by 3D Solution Center

*You can check the details of Stereolithography Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser. here.

Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser. here.

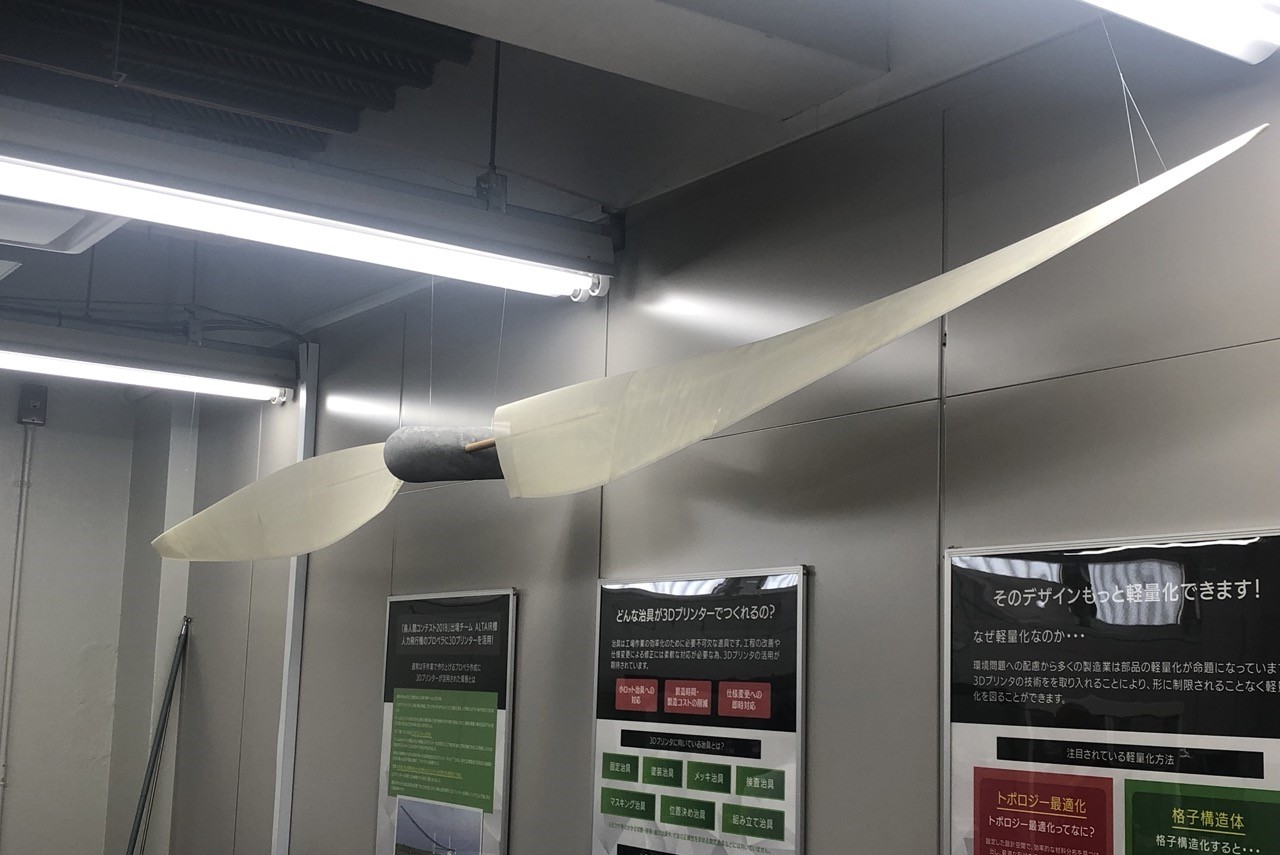

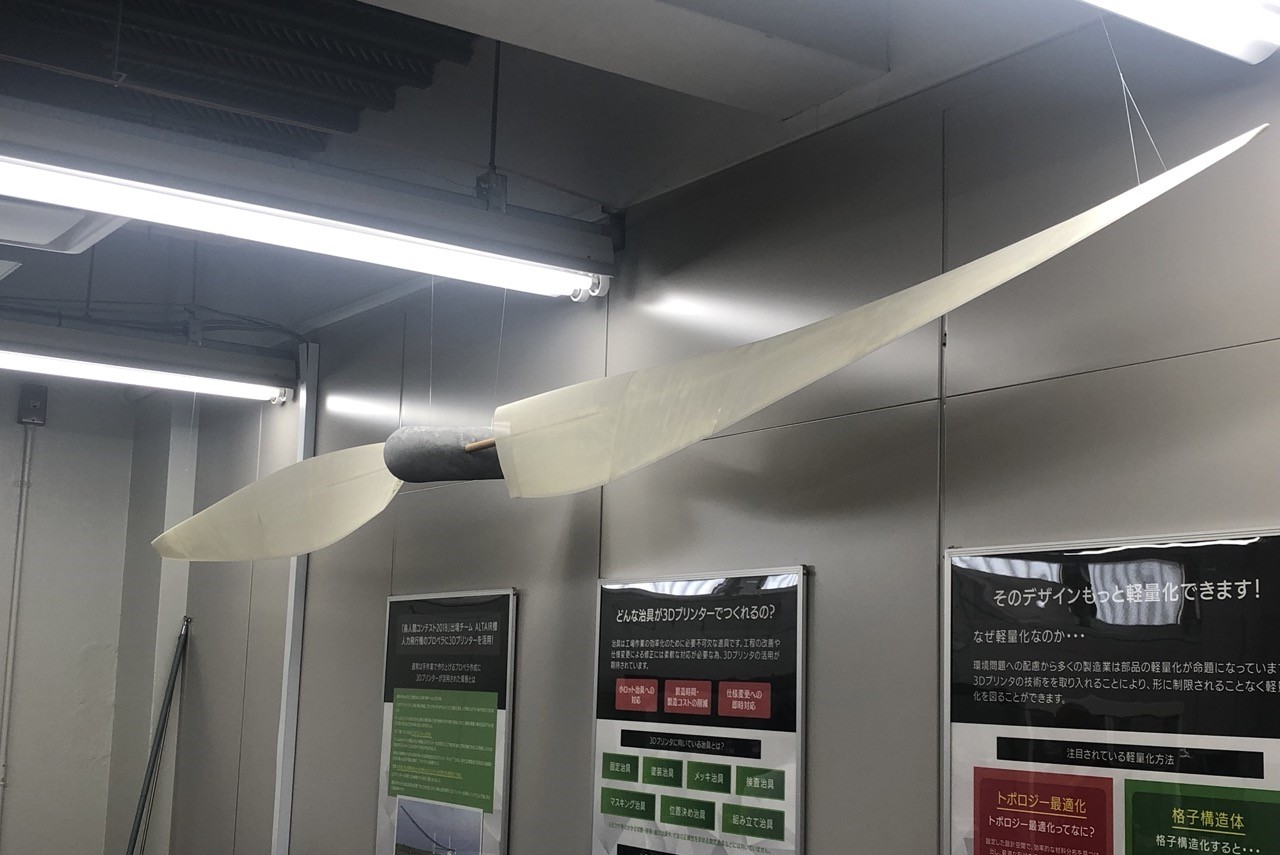

The following photograph is a propeller printed with a 3D printer (Selective Laser Sintering Selective Laser Sintering is a method that draws each layer by emitting a laser to the flattened powder and solidifying them.)!

Selective Laser Sintering is a method that draws each layer by emitting a laser to the flattened powder and solidifying them.)!

Place: 3D Solution Center

▲Propeller hanging from the ceiling.

Created to participate in the JAPAN INTERNATIONAL BIRDMAN RALLY, the 30 cm square parts are joined together to form a single propeller.

The characteristics of the 3D printer, which can hollow out the interior, are well utilized to reduce the weight of the airframe.

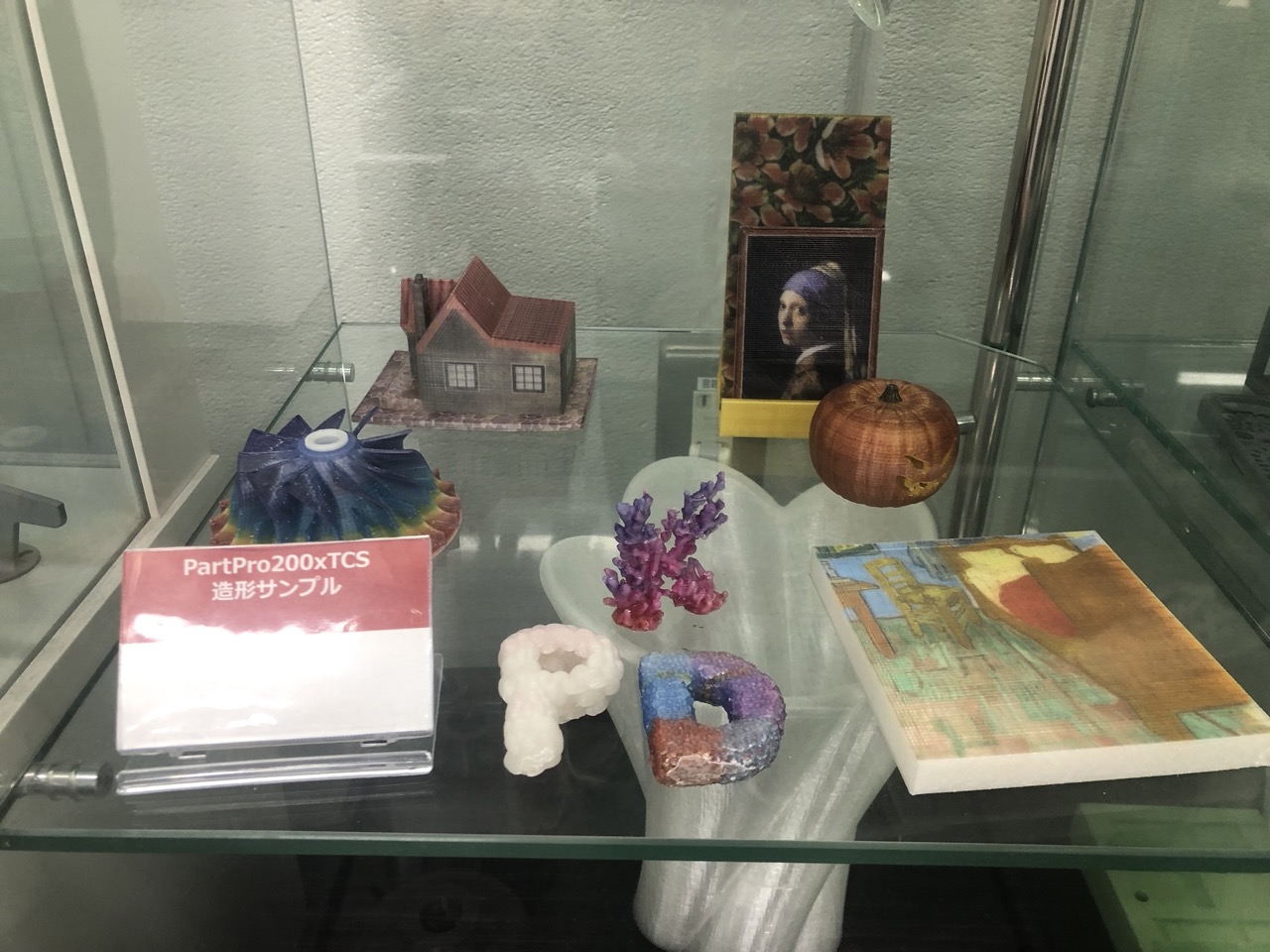

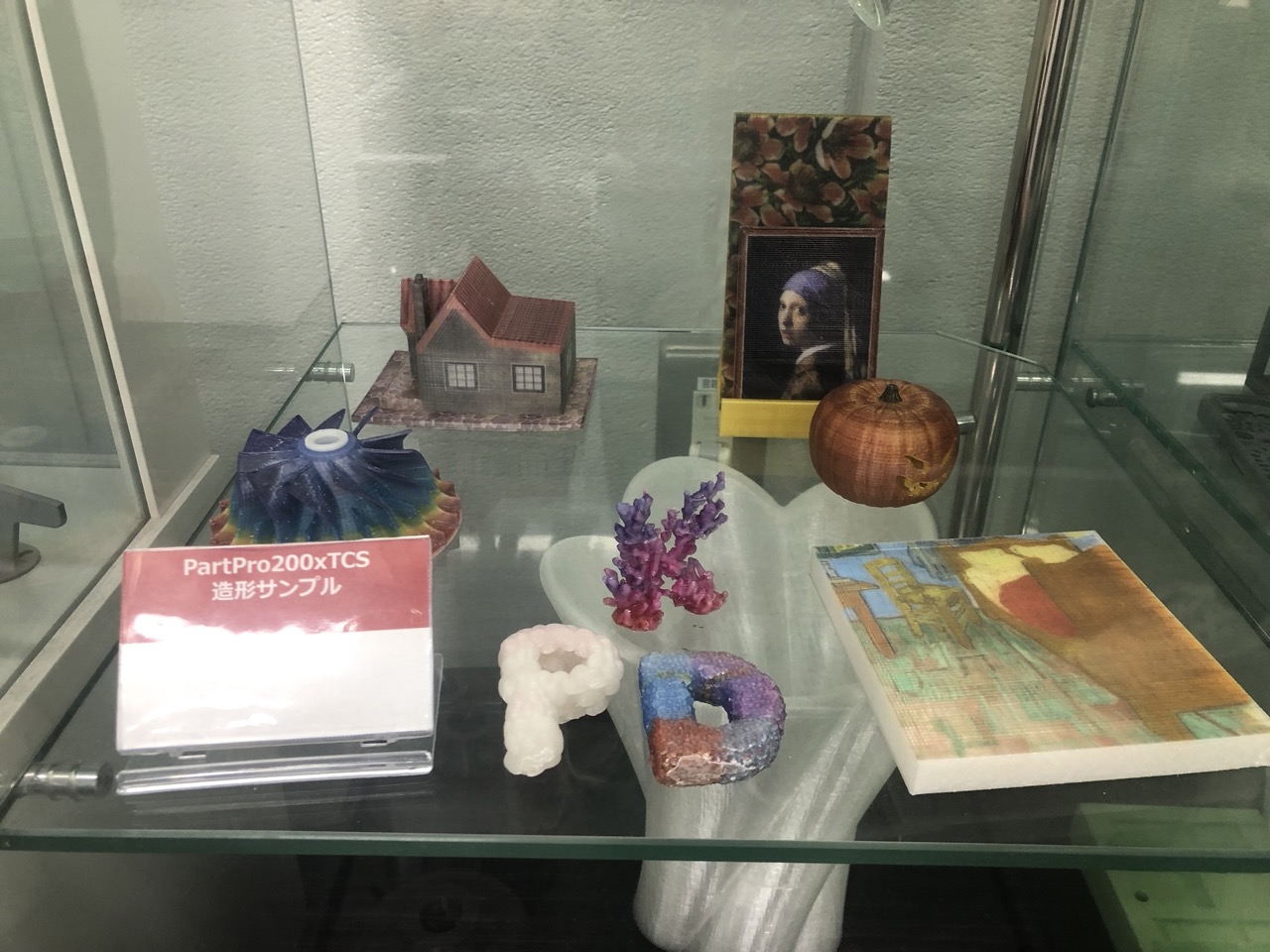

There were a lot of objects printed with 3D printers.

Place: 3D Solution Center

▲Picture of objects printed with 3D printers.

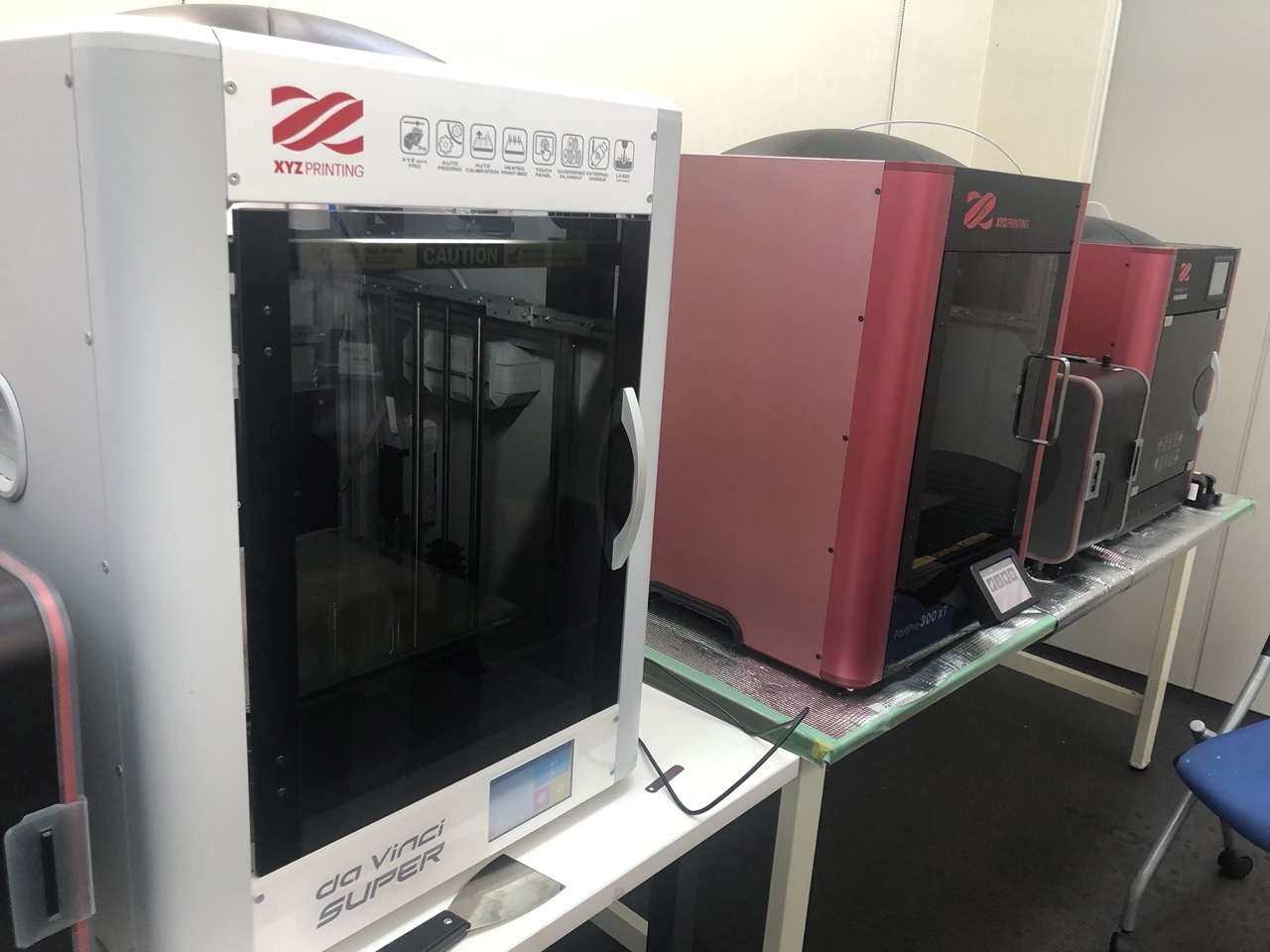

There were exhibits of Stereolithography Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser., Fused Filament Fabrication

Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser., Fused Filament Fabrication Fused Filament Fabrication is a method that draws each layer and stacks it by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle., and MultiJet Printing

Fused Filament Fabrication is a method that draws each layer and stacks it by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle., and MultiJet Printing MultiJet Printing is a method that draws each layer and stacks it by jetting resin from inkjet head and are solidified them with a UV laser. on the 2nd floor.

MultiJet Printing is a method that draws each layer and stacks it by jetting resin from inkjet head and are solidified them with a UV laser. on the 2nd floor.

▲Picture of 2nd floor.

Place: 3D Solution Center

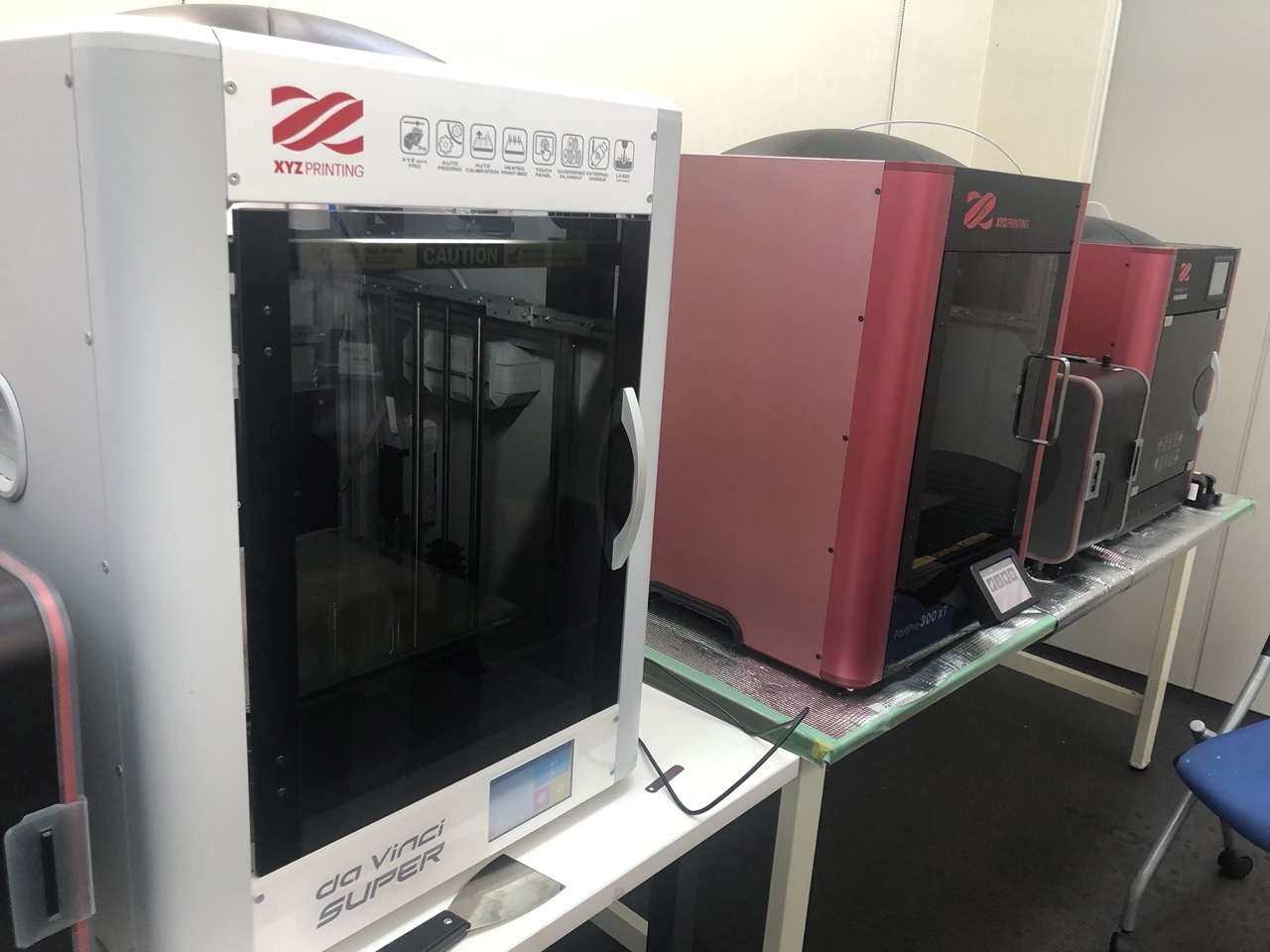

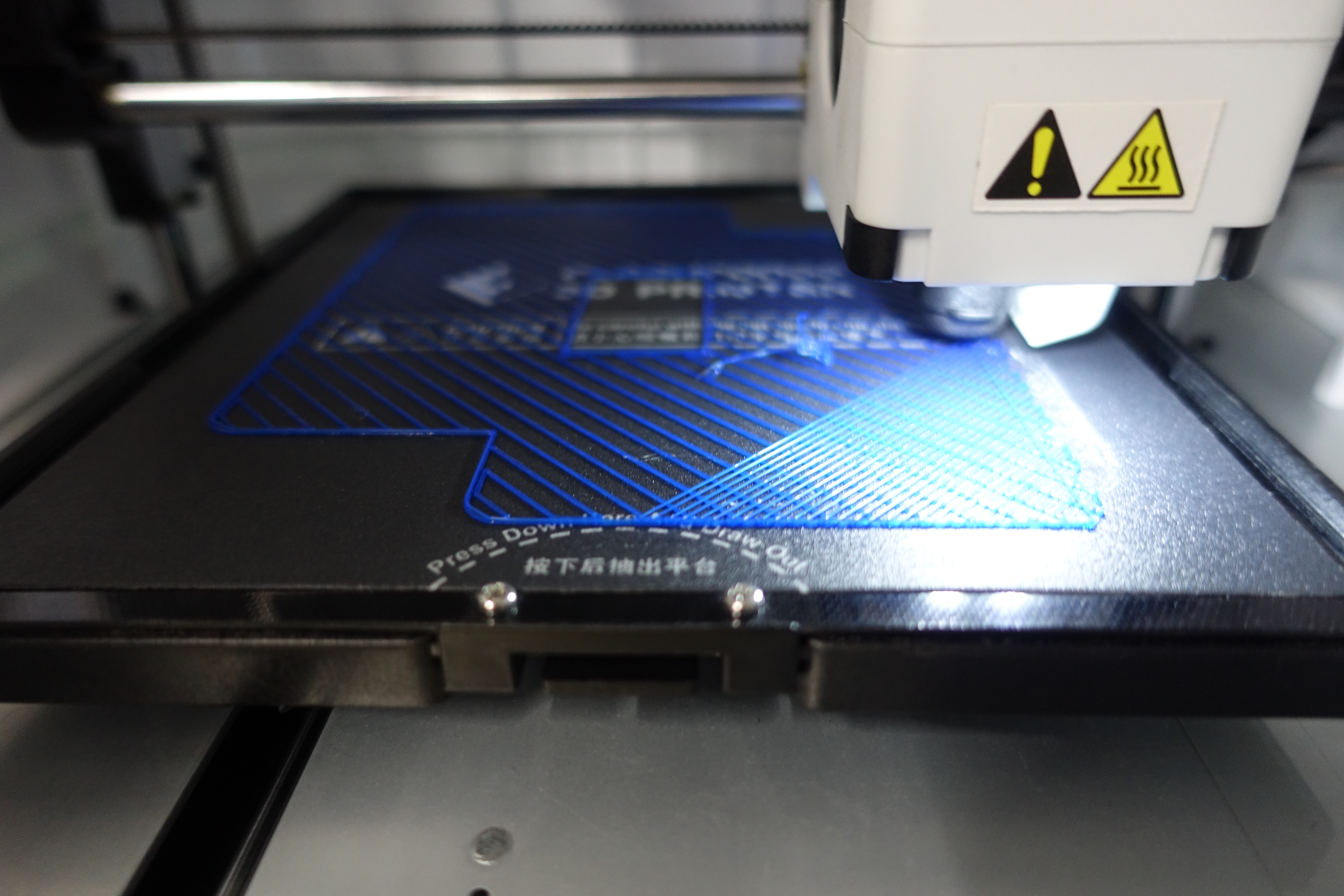

Fused Filament Fabrication Fused Filament Fabrication is a method that draws each layer and stacks them by extruding resin from the heated nozzle and changing the relative position between the stage

Fused Filament Fabrication is a method that draws each layer and stacks them by extruding resin from the heated nozzle and changing the relative position between the stage A stage is the foundation on which moldings are printed in a 3D printer. and nozzle

A stage is the foundation on which moldings are printed in a 3D printer. and nozzle A nozzle is a component that extrudes filament (resin) and prints it on the stage.. creates a cross-sectional shape by changing the relative position of the stage and nozzle

A nozzle is a component that extrudes filament (resin) and prints it on the stage.. creates a cross-sectional shape by changing the relative position of the stage and nozzle A nozzle is a component that extrudes filament (resin) and prints it on the stage., and then laminates the molten resin extruded from the heating nozzle

A nozzle is a component that extrudes filament (resin) and prints it on the stage., and then laminates the molten resin extruded from the heating nozzle A nozzle is a component that extrudes filament (resin) and prints it on the stage.. This is the mainstream method for home-use 3D printer

A nozzle is a component that extrudes filament (resin) and prints it on the stage.. This is the mainstream method for home-use 3D printer A home-use 3D printer is one intended for personal purchase. Although home-use 3D printers are less precise than industrial-use printers, they are less expensive, with some printers costing less than 50,000 yen. due to its superior cost performance.

A home-use 3D printer is one intended for personal purchase. Although home-use 3D printers are less precise than industrial-use printers, they are less expensive, with some printers costing less than 50,000 yen. due to its superior cost performance.

Place: 3D Solution Center

▲From left to right, are da Vinci Super, PartPro300 xT, and PartPro200 xTCS. (Manufactured by XYZ PRINTING)

Place: 3D Solution Center

▲The printed objects made with Fused Filament Fabrication Fused Filament Fabrication is a method that draws each layer and stacks it by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle.

Fused Filament Fabrication is a method that draws each layer and stacks it by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle.

*You can check the details of Fused Filament Fabrication Fused Filament Fabrication is a method that draws each layer and stacks it by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle. here.

Fused Filament Fabrication is a method that draws each layer and stacks it by extruding resin from the heated nozzle and changing the relative position between the stage and nozzle. here.

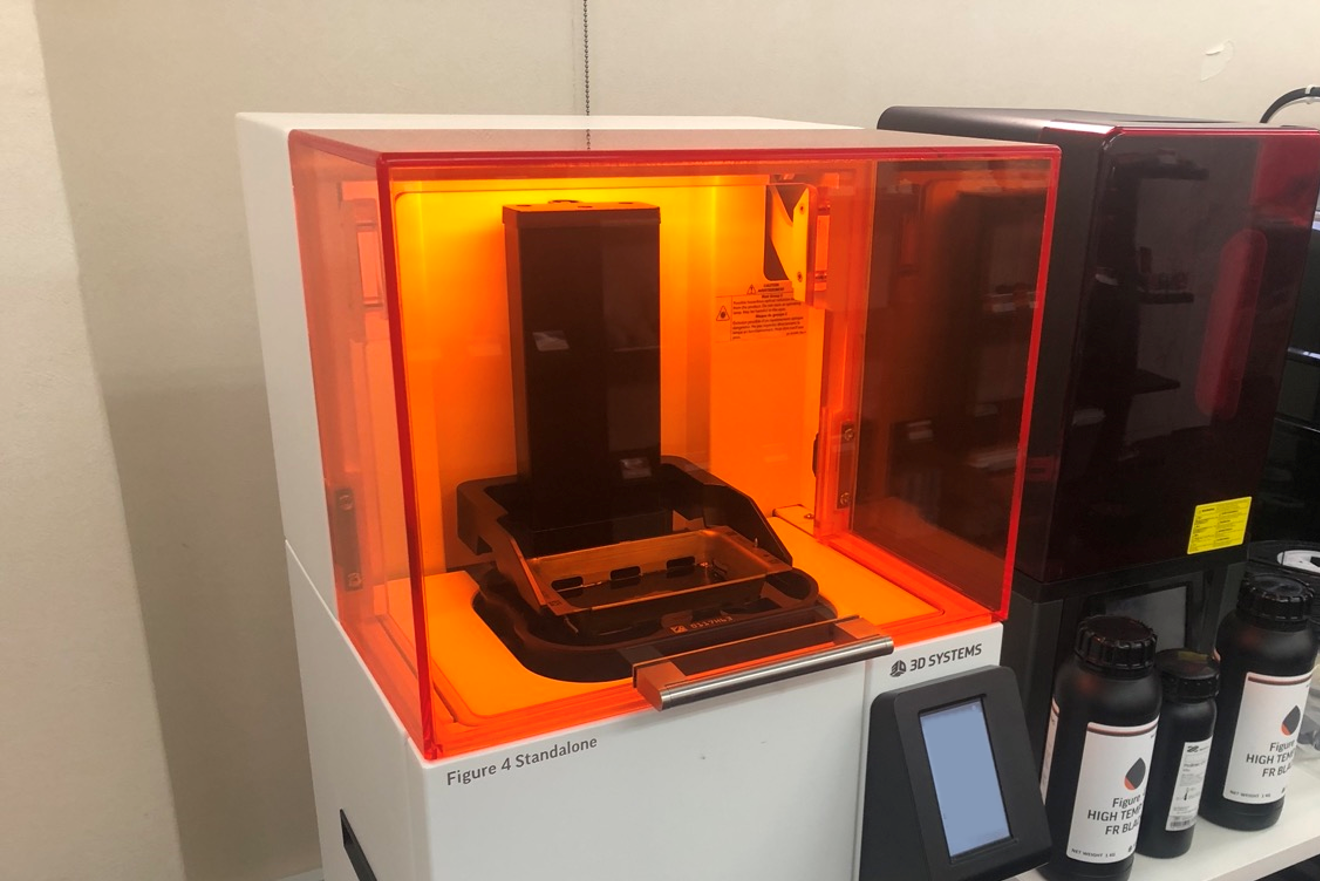

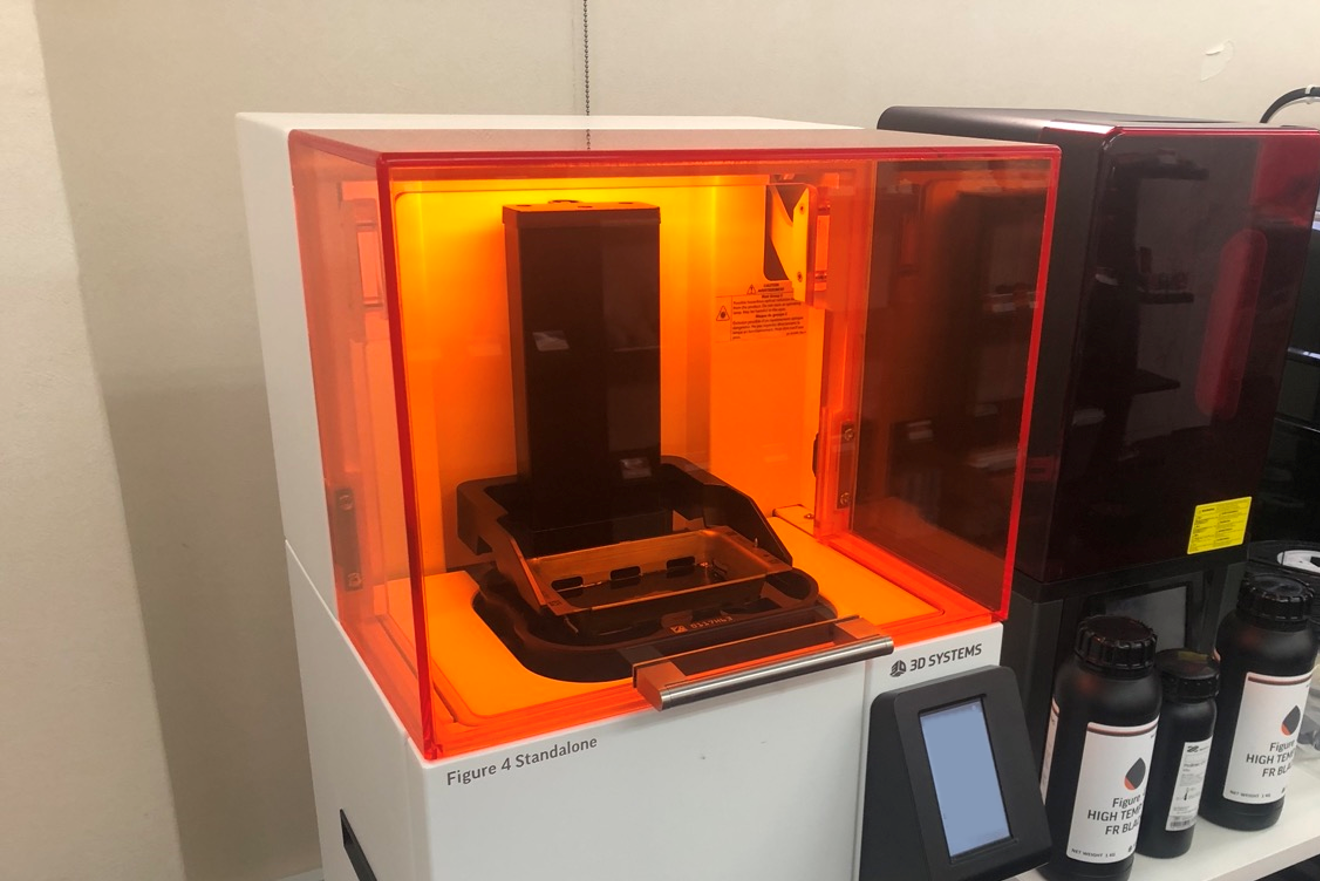

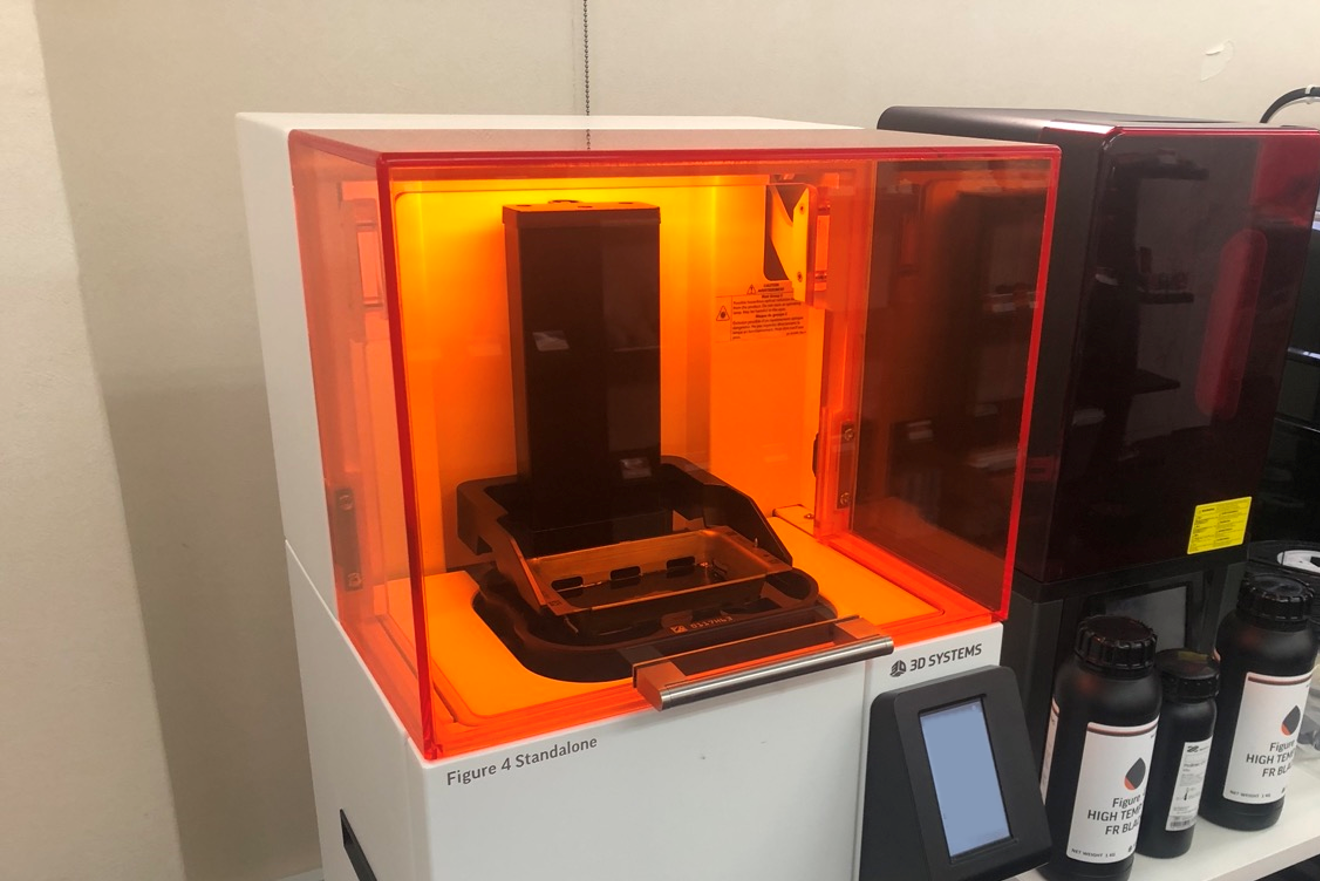

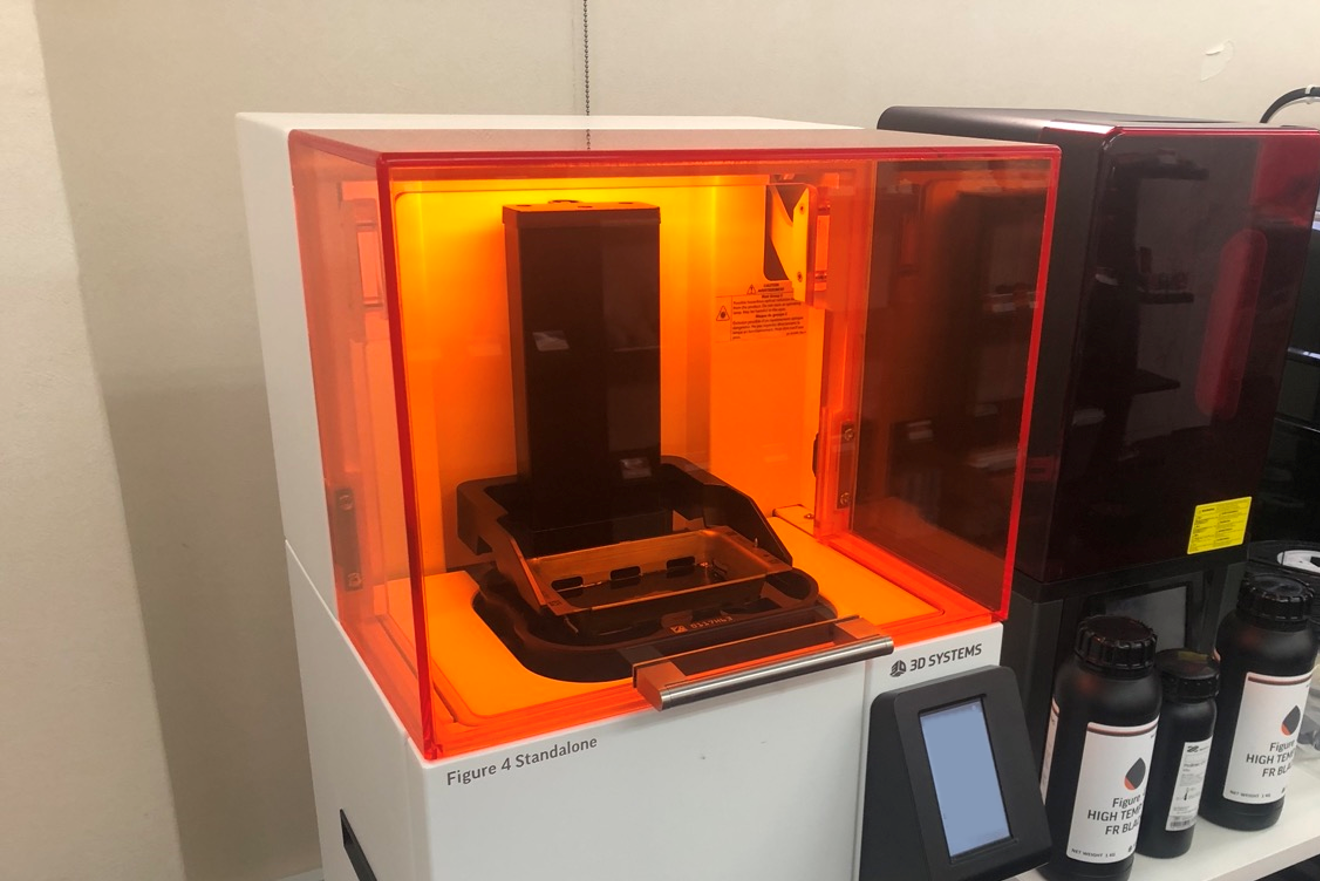

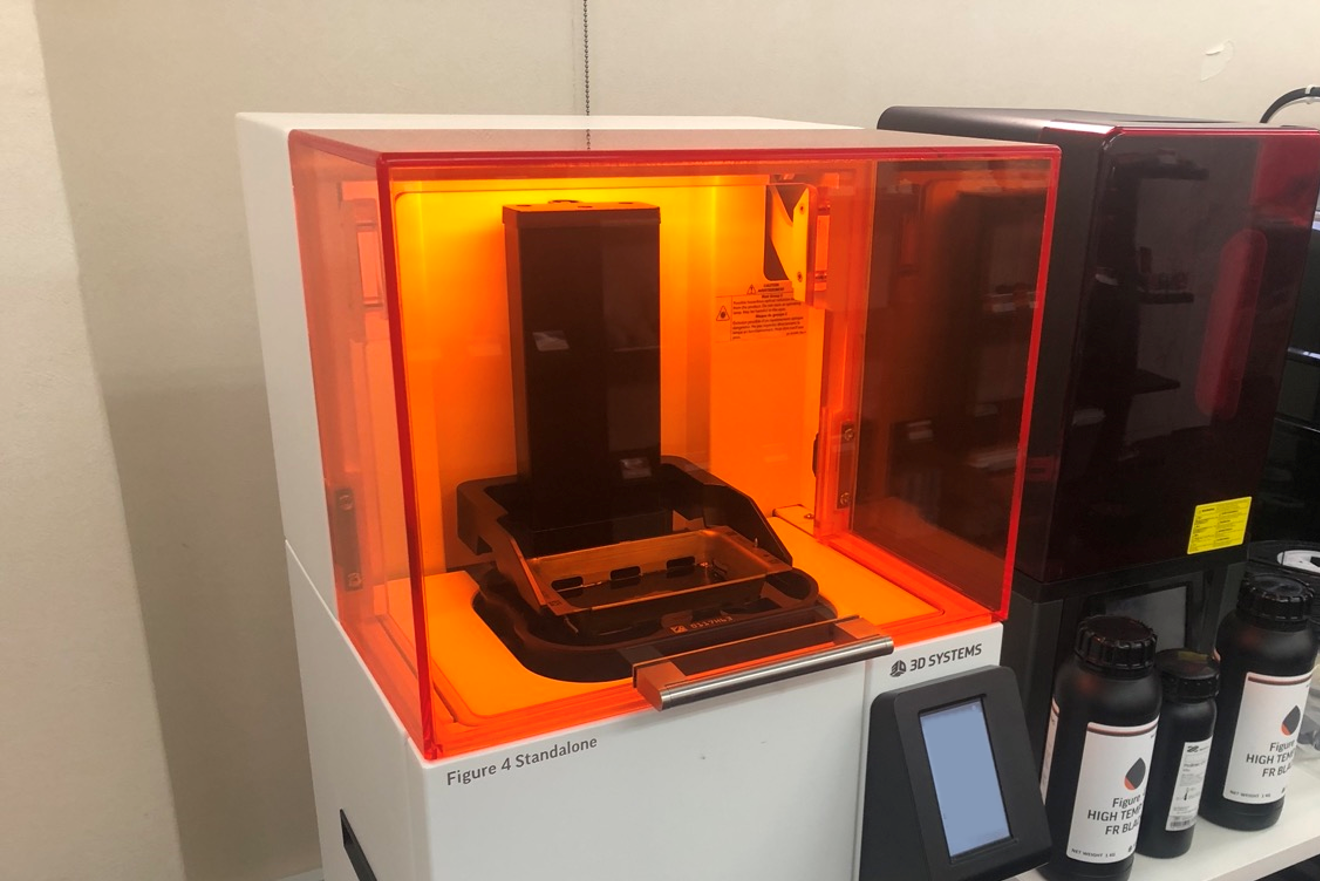

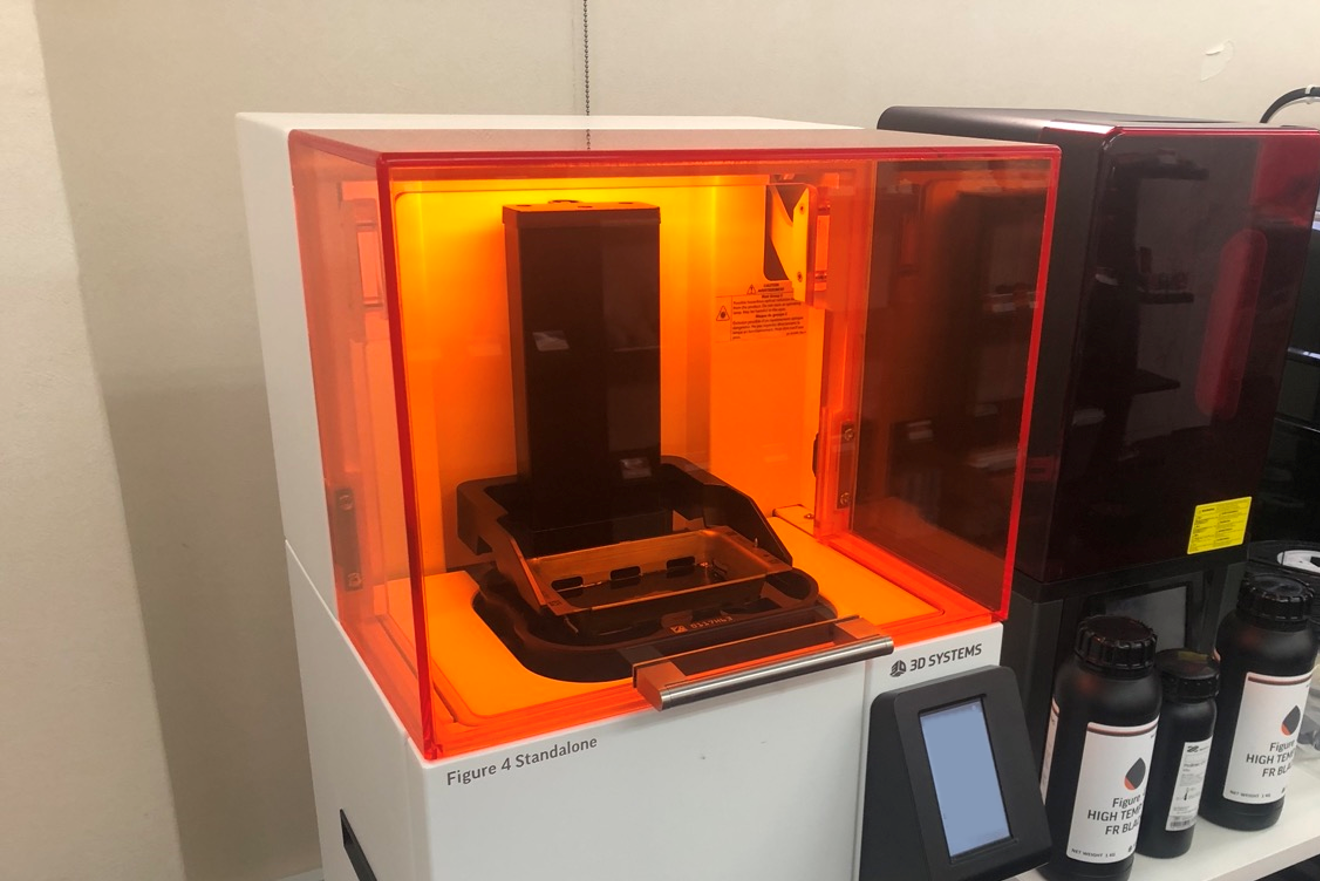

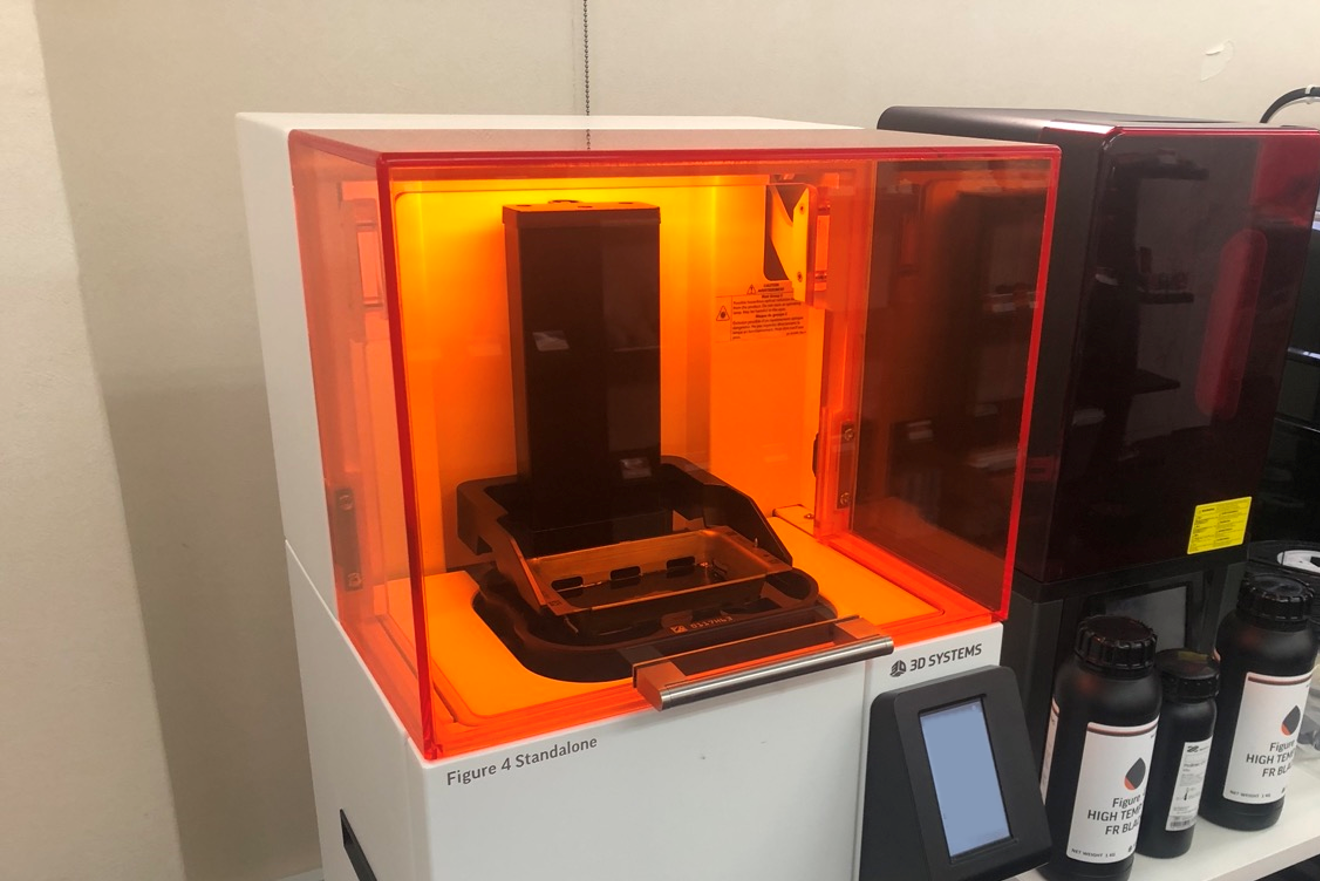

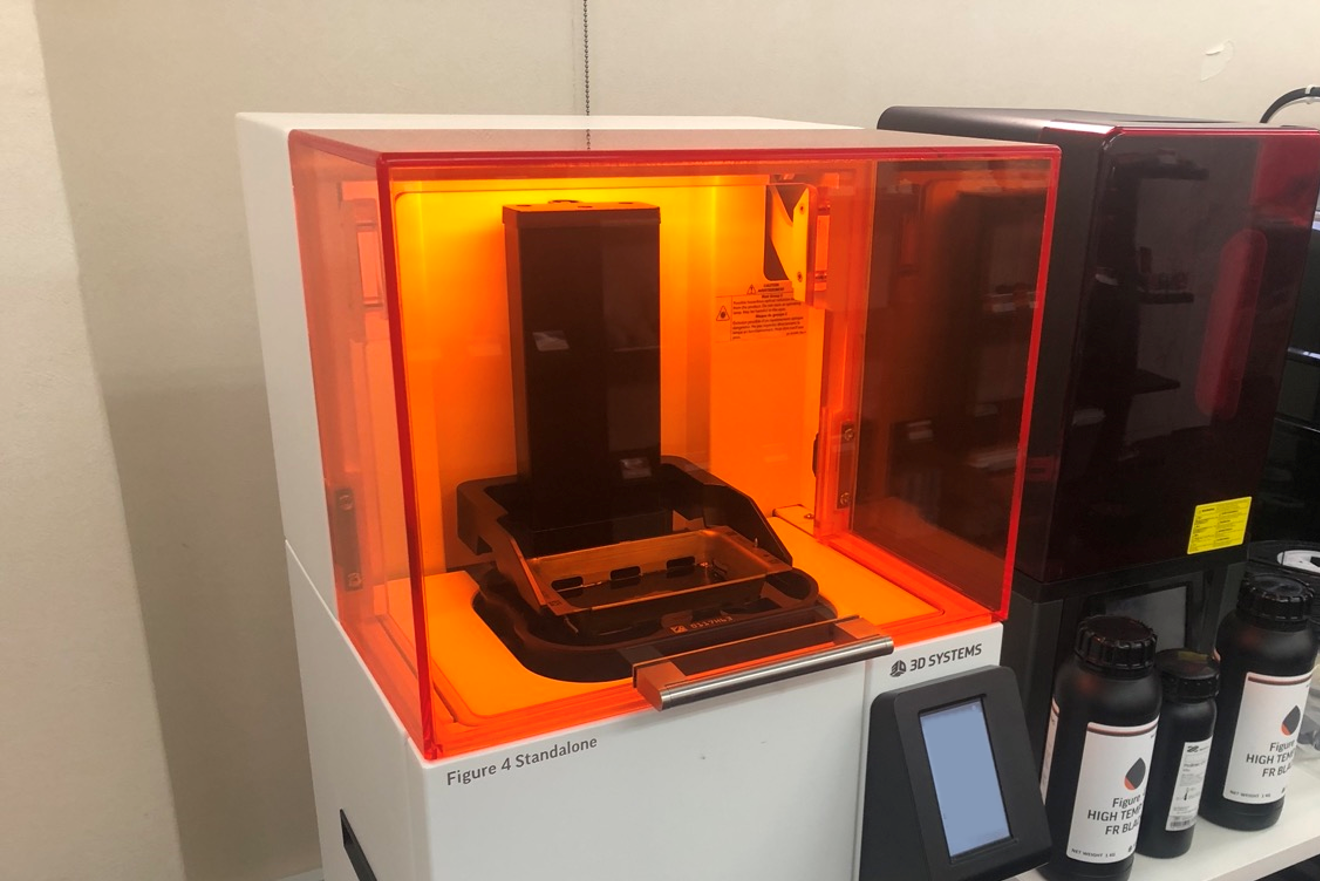

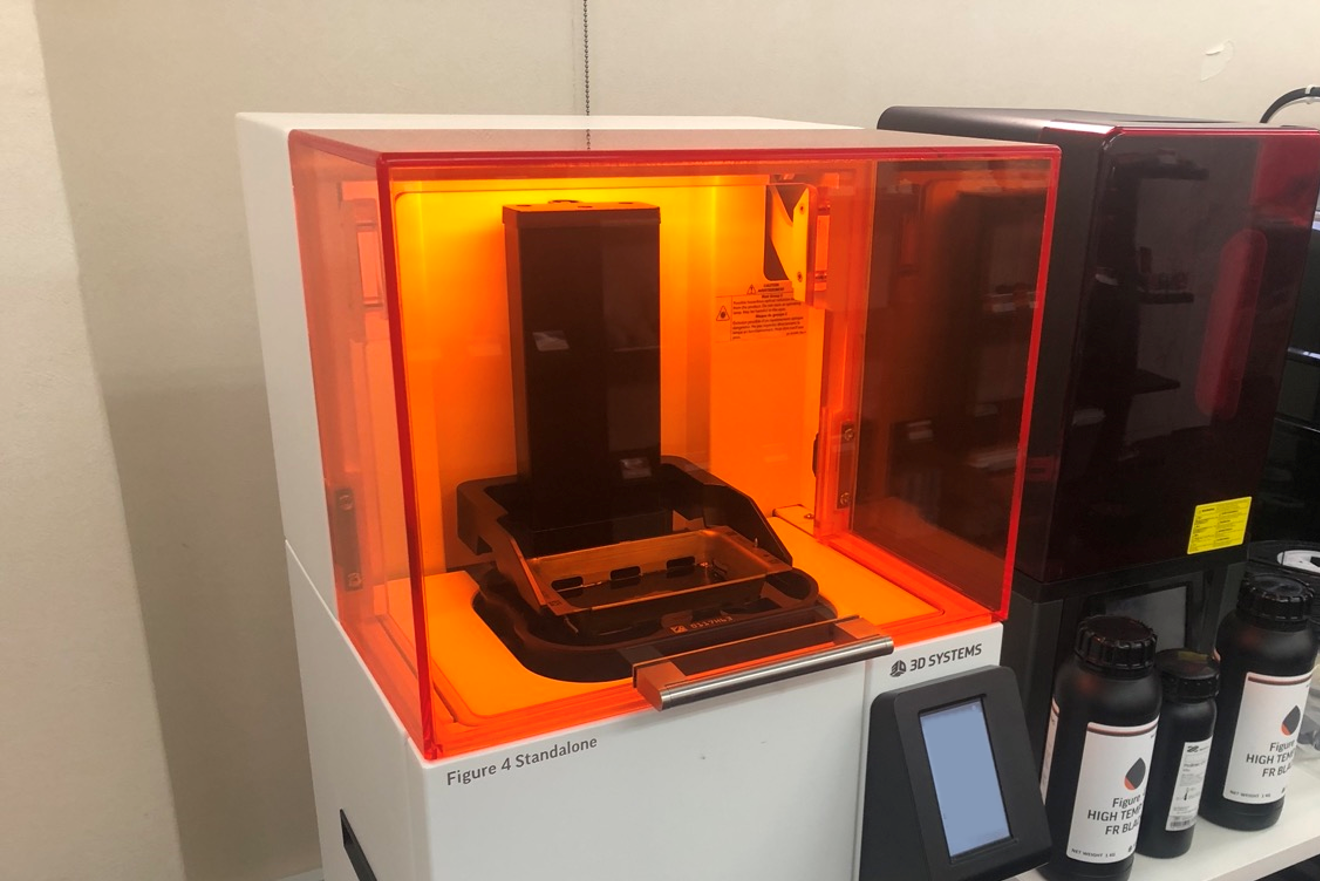

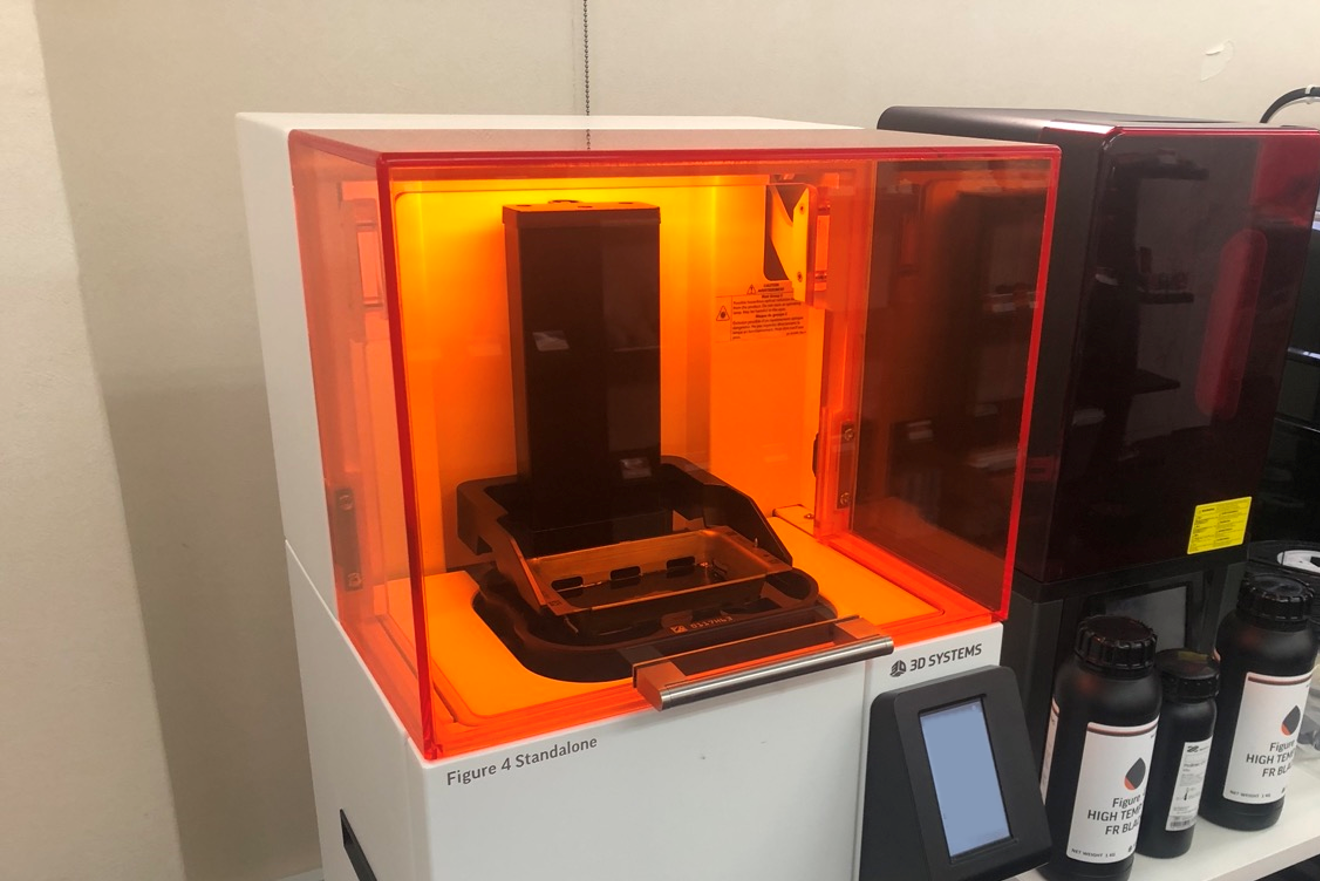

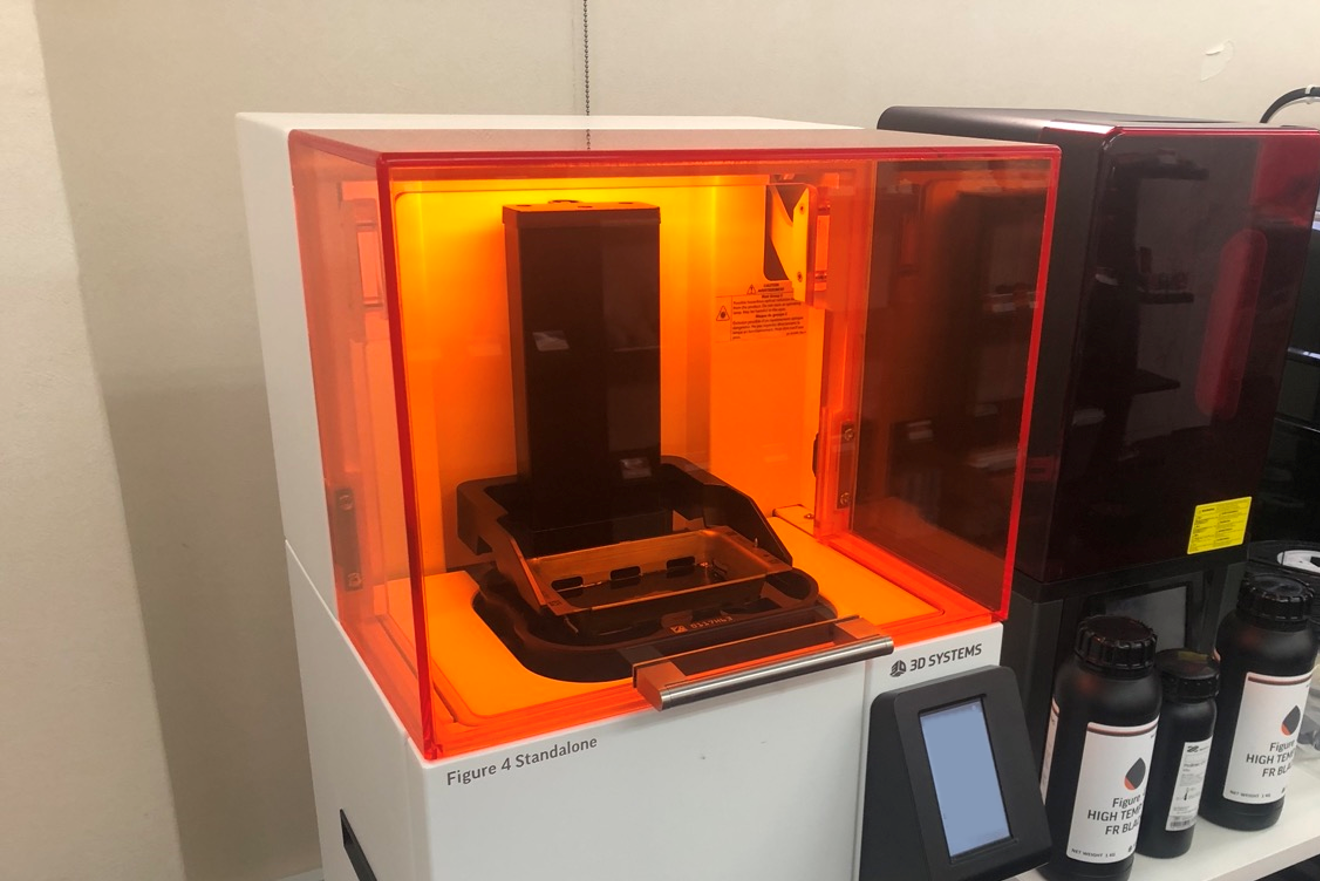

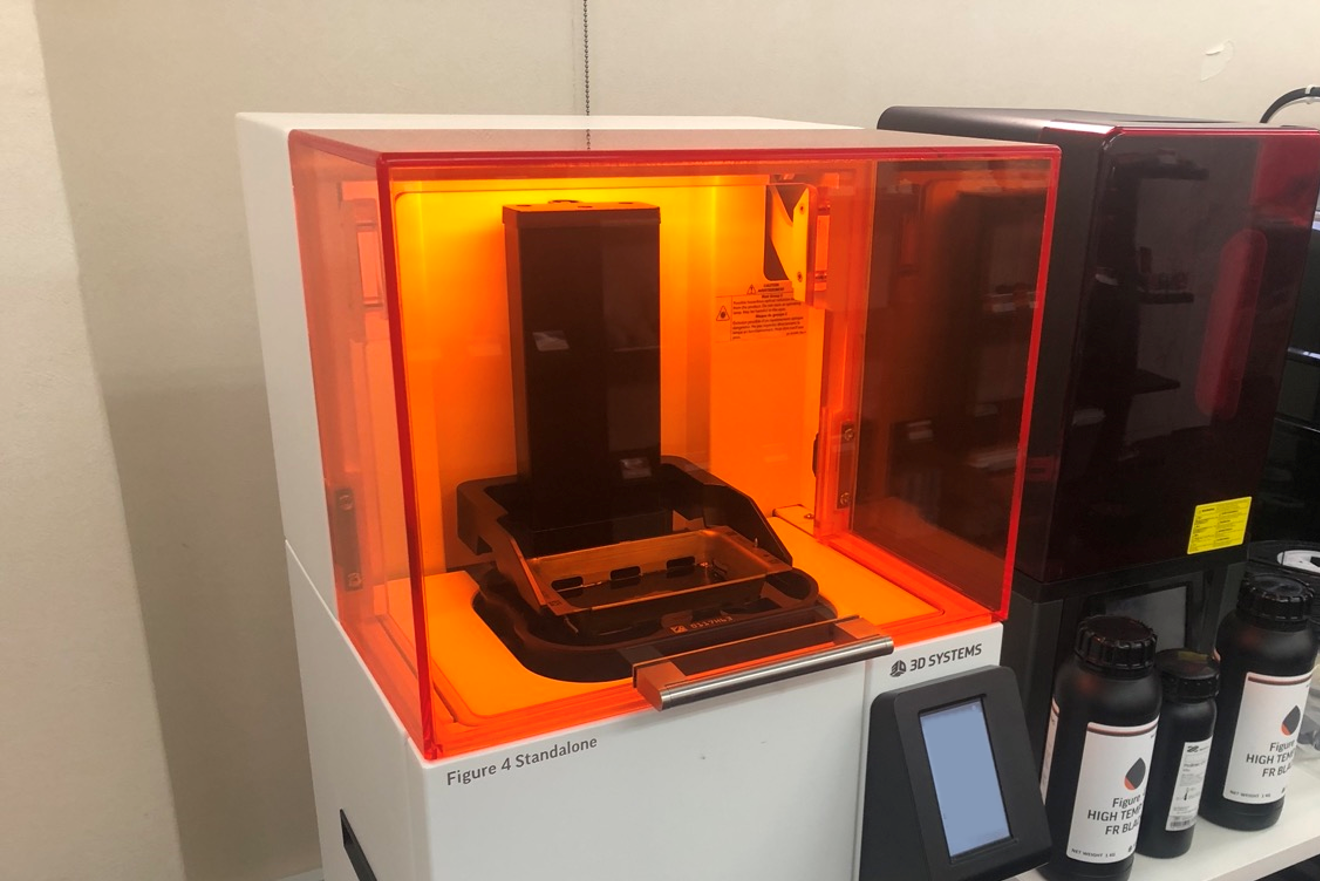

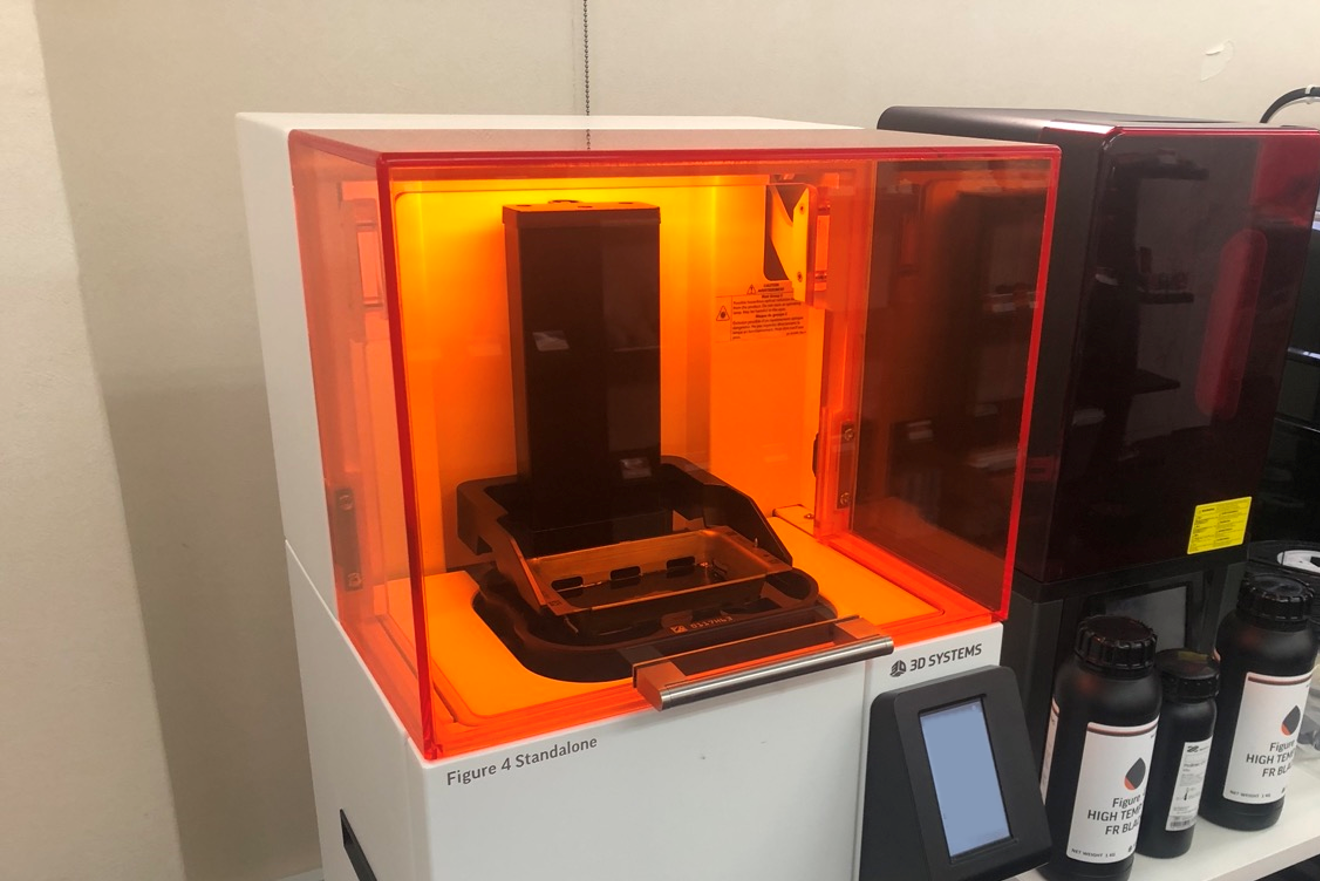

Stereolithography Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser. creates a cross-sectional shape by illuminating liquid resin

Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser. creates a cross-sectional shape by illuminating liquid resin Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. with light to harden the resin, which is then layered. It has the longest history of all 3D printer types and is characterized by its smooth surface finish.

Liquid resin is a resin that hardens when exposed to ultraviolet light. In the Stereolithography, liquid resin (UV resin) is used for modeling. with light to harden the resin, which is then layered. It has the longest history of all 3D printer types and is characterized by its smooth surface finish.

Place: 3D Solution Center

▲Figure 4 Standalone (Manufactured by 3D Systems)

Provided by 3D Solution Center

▲The printed objects made with Stereolithography Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser.

Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser.

*You can check the details of Stereolithography Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser. here.

Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser. here.

MultiJet Printing MultiJet Printing is a method that draws each layer and stacks it by jetting resin from inkjet head and are solidified them with a UV laser. uses UV light to solidify the resin injected from the inkjet printhead

MultiJet Printing is a method that draws each layer and stacks it by jetting resin from inkjet head and are solidified them with a UV laser. uses UV light to solidify the resin injected from the inkjet printhead An inkjet printhead is a movable device in an inkjet printer through which ink is sprayed. as it is layered. Because the layering pitch

An inkjet printhead is a movable device in an inkjet printer through which ink is sprayed. as it is layered. Because the layering pitch Layer resolution is the thickness of each layer of the 3D model. The smaller the thickness is, the more accurate the printing will be. is thin, very fine modeling can be printed.

Layer resolution is the thickness of each layer of the 3D model. The smaller the thickness is, the more accurate the printing will be. is thin, very fine modeling can be printed.

Provided by 3D Solution Center

▲ProJet MJP 2500Plus (Manufactured by 3D Systems)

Provided by 3D Solution Center

▲The printed objects made with MultiJet Printing MultiJet Printing is a method that draws each layer and stacks it by jetting resin from inkjet head and are solidified them with a UV laser.

MultiJet Printing is a method that draws each layer and stacks it by jetting resin from inkjet head and are solidified them with a UV laser.

*You can check the details of MultiJet Printing MultiJet Printing is a method that draws each layer and stacks it by jetting resin from inkjet head and are solidified them with a UV laser. here.

MultiJet Printing is a method that draws each layer and stacks it by jetting resin from inkjet head and are solidified them with a UV laser. here.

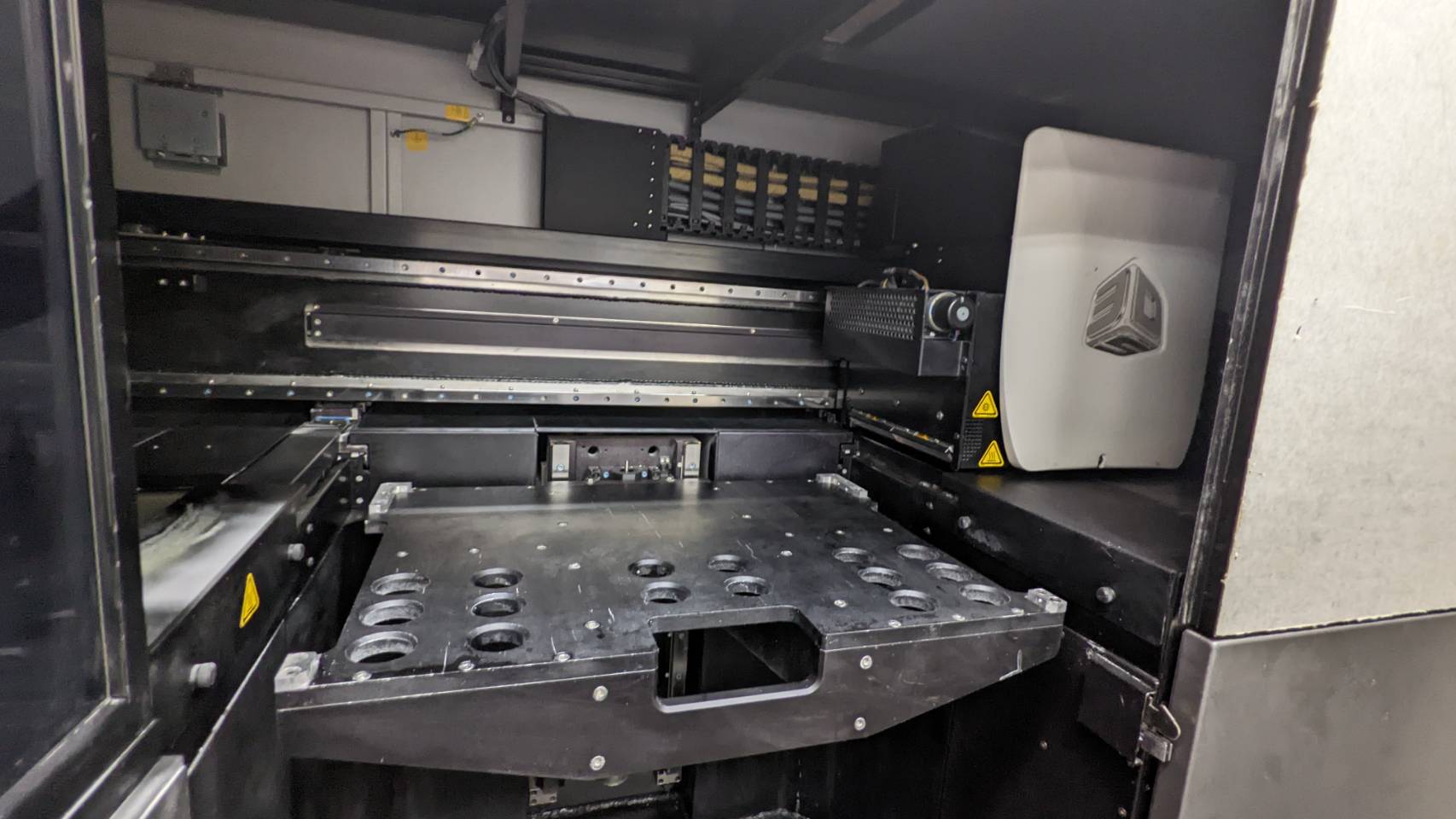

There were Selective Laser Sintering Selective Laser Sintering is a method that draws each layer by emitting a laser to the flattened powder and solidifying them. and Binder Jetting

Selective Laser Sintering is a method that draws each layer by emitting a laser to the flattened powder and solidifying them. and Binder Jetting Binder Jetting is a method that draws each layer by emitting binder from the head to the flattened powder and solidifies them. It is, in some cases, categorized as MultiJet Printing. on the 1st floor.

Binder Jetting is a method that draws each layer by emitting binder from the head to the flattened powder and solidifies them. It is, in some cases, categorized as MultiJet Printing. on the 1st floor.

Provided by 3D Solution Center

▲Picture of 1st floor.

Selective Laser Sintering Selective Laser Sintering is a method that draws each layer by emitting a laser to the flattened powder and solidifying them. is a method that draws each layer by emitting a laser to the flattened powder and solidifying them. It usually uses nylonNylon is a type of synthetic fiber made from petroleum. It has excellent durability and heat resistance and is mainly used as a printing material for powder Selective Laser Sintering. There are various types such as nylon 6, nylon 11, and nylon 12. as a material, but some products can use metal.

Selective Laser Sintering is a method that draws each layer by emitting a laser to the flattened powder and solidifying them. is a method that draws each layer by emitting a laser to the flattened powder and solidifying them. It usually uses nylonNylon is a type of synthetic fiber made from petroleum. It has excellent durability and heat resistance and is mainly used as a printing material for powder Selective Laser Sintering. There are various types such as nylon 6, nylon 11, and nylon 12. as a material, but some products can use metal.

Provided by 3D Solution Center

▲MfgPro230 xS (Manufactured by XYZ PRINTING)

Place: 3D Solution Center

▲The printed objects made with Selective Laser Sintering Selective Laser Sintering is a method that draws each layer by emitting a laser to the flattened powder and solidifying them.

Selective Laser Sintering is a method that draws each layer by emitting a laser to the flattened powder and solidifying them.

*You can check the details of Selective Laser Sintering Selective Laser Sintering is a method that draws each layer by emitting a laser to the flattened powder and solidifying them. here.

Selective Laser Sintering is a method that draws each layer by emitting a laser to the flattened powder and solidifying them. here.

Binder Jetting Binder Jetting is a method that draws each layer by emitting binder from the head to the flattened powder and solidifies them. It is, in some cases, categorized as MultiJet Printing. is, in some cases, categorized into MultiJet Printing

Binder Jetting is a method that draws each layer by emitting binder from the head to the flattened powder and solidifies them. It is, in some cases, categorized as MultiJet Printing. is, in some cases, categorized into MultiJet Printing MultiJet Printing is a method that draws each layer and stacks it by jetting resin from inkjet head and are solidified them with a UV laser., which draws each layer by emitting binderAdhesives are also called binders or binding agents. In the Binder Jetting, the powder is bonded (cured) to form a cross section by printing this adhesive on the layered powder. from the head to the flattened powder and solidifying them. In addition, Binder Jetting can print full-color objects using a dyed binderAdhesives are also called binders or binding agents. In the Binder Jetting, the powder is bonded (cured) to form a cross section by printing this adhesive on the layered powder..

MultiJet Printing is a method that draws each layer and stacks it by jetting resin from inkjet head and are solidified them with a UV laser., which draws each layer by emitting binderAdhesives are also called binders or binding agents. In the Binder Jetting, the powder is bonded (cured) to form a cross section by printing this adhesive on the layered powder. from the head to the flattened powder and solidifying them. In addition, Binder Jetting can print full-color objects using a dyed binderAdhesives are also called binders or binding agents. In the Binder Jetting, the powder is bonded (cured) to form a cross section by printing this adhesive on the layered powder..

Provided by 3D Solution Center

▲ProJet 660Pro (Manufactured by 3D Systems)

Provided by 3D Solution Center

▲PartPro350 xBC (Manufactured by XYZ PRINTING)

Place: 3D Solution Center

▲The printed objects made with Binder Jetting Binder Jetting is a method that draws each layer by emitting binder from the head to the flattened powder and solidifies them. It is, in some cases, categorized as MultiJet Printing.

Binder Jetting is a method that draws each layer by emitting binder from the head to the flattened powder and solidifies them. It is, in some cases, categorized as MultiJet Printing.

*You can check the details of Binder Jetting Binder Jetting is a method that draws each layer by emitting binder from the head to the flattened powder and solidifies them. It is, in some cases, categorized as MultiJet Printing. here.

Binder Jetting is a method that draws each layer by emitting binder from the head to the flattened powder and solidifies them. It is, in some cases, categorized as MultiJet Printing. here.

There were also many types of equipment that vacuum powder and are used for safety.

Place: 3D Solution Center

▲Depowdering station In Selective Laser Sintering, Binder Jetting, a device that removes and reuses excess powder adhered after printing is completed.

In Selective Laser Sintering, Binder Jetting, a device that removes and reuses excess powder adhered after printing is completed.

Place: 3D Solution Center

▲Dust extractor A dust extractor is a device that collects dust from the air.

A dust extractor is a device that collects dust from the air.

Provided by 3D Solution Center

▲Powder collector

Provided by 3D Solution Center

▲Vacuum cleaner

Provided by 3D Solution Center

▲Nitrogen generator A nitrogen generator is, as the name implies, a device that generates nitrogen. In a powder Selective Laser Sintering, nitrogen is filled inside the printer to avoid dust explosions.

A nitrogen generator is, as the name implies, a device that generates nitrogen. In a powder Selective Laser Sintering, nitrogen is filled inside the printer to avoid dust explosions.

We learned at IGUAZU 3D Solution Center about many methods of 3D printers we had never seen. In addition, there were a lot of printed objects, and we could feel something different among those products.

Thank you to the IGUAZU 3D Solution Center for the interview.

Here are the pictures of 3D printers and printed objects taken at IGUAZU 3D Solution Center.

Place: 3D Solution Center

Exterior view of the IGUAZU 3D Solution Center

Place: 3D Solution Center

Team members receiving an explanation

Provided by 3D Solution Center

Picture of 1st floor.

Place: 3D Solution Center

Picture of 2nd floor.

Place: 3D Solution Center

Figure 4 Standalone (Manufactured by 3D Systems)

Provided by 3D Solution Center

MfgPro230 xS (Manufactured by XYZ PRINTING)

Place: 3D Solution Center

The printed objects made with Selective Laser Sintering

Provided by 3D Solution Center

From left to right, are PartPro120 xP and PartPro150 xP. (Manufactured by XYZ PRINTING)

Provided by 3D Solution Center

The printed objects made with Stereolithography

Place: 3D Solution Center

Picture of the hanging propeller.

Place: 3D Solution Center

Picture of objects printed with 3D printers.

Place: 3D Solution Center

From left to right, are da Vinci Super, PartPro300 xT, and PartPro200 xTCS. (Manufactured by XYZ PRINTING)

Place: 3D Solution Center

The printed objects made with Fused Filament Fabrication

Provided by 3D Solution Center

The printed objects made with Stereolithography

Provided by 3D Solution Center

ProJet MJP 2500Plus (Manufactured by 3D Systems)

Provided by 3D Solution Center

The printed objects made with MultiJet Printing

Place: 3D Solution Center

The printed objects made with Selective Laser Sintering

Provided by 3D Solution Center

ProJet 660Pro (Manufactured by 3D Systems)

Provided by 3D Solution Center

PartPro350 xBC(Manufactured by XYZ PRINTING)

Place: 3D Solution Center

The printed objects made with Binder Jetting

Place: 3D Solution Center

Depowdering station

Place: 3D Solution Center

Dust extractor

Provided by 3D Solution Center

Powder collector

Provided by 3D Solution Center

Vacuum cleaner

Provided by 3D Solution Center

Nitrogen generator