Fused Filament Fabrication

Fused Filament Fabrication is a method that draws each layer and stacks them by extruding resin from the heated nozzle A nozzle is a component that extrudes filament (resin) and prints it on the stage. and changing the relative position between the stage

A nozzle is a component that extrudes filament (resin) and prints it on the stage. and changing the relative position between the stage A stage is the foundation on which moldings are printed in a 3D printer. and nozzle

A stage is the foundation on which moldings are printed in a 3D printer. and nozzle A nozzle is a component that extrudes filament (resin) and prints it on the stage.. We’ll introduce the feature and printing process of Fused Filament Fabrication on this page.

A nozzle is a component that extrudes filament (resin) and prints it on the stage.. We’ll introduce the feature and printing process of Fused Filament Fabrication on this page.

Table of Contents

The table is the basic information list of Fused Filament Fabrication.

| ISO standards | Material Extrusion |

|---|---|

| Aliases | FFF, FDM |

| Cost | Inexpensive |

| Performance | A little bit not good |

How can we print 3D objects with Fused Filament Fabrication?

We can make objects by putting filament Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. into a heated nozzle

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. into a heated nozzle A nozzle is a component that extrudes filament (resin) and prints it on the stage. installed in the 3D printer. The 3D printer melts the filament

A nozzle is a component that extrudes filament (resin) and prints it on the stage. installed in the 3D printer. The 3D printer melts the filament Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. and prints an object. It looked like a 3D printer was painting a picture.

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. and prints an object. It looked like a 3D printer was painting a picture.

Place: Dengiken's club room

▲Filament Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle.

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle.

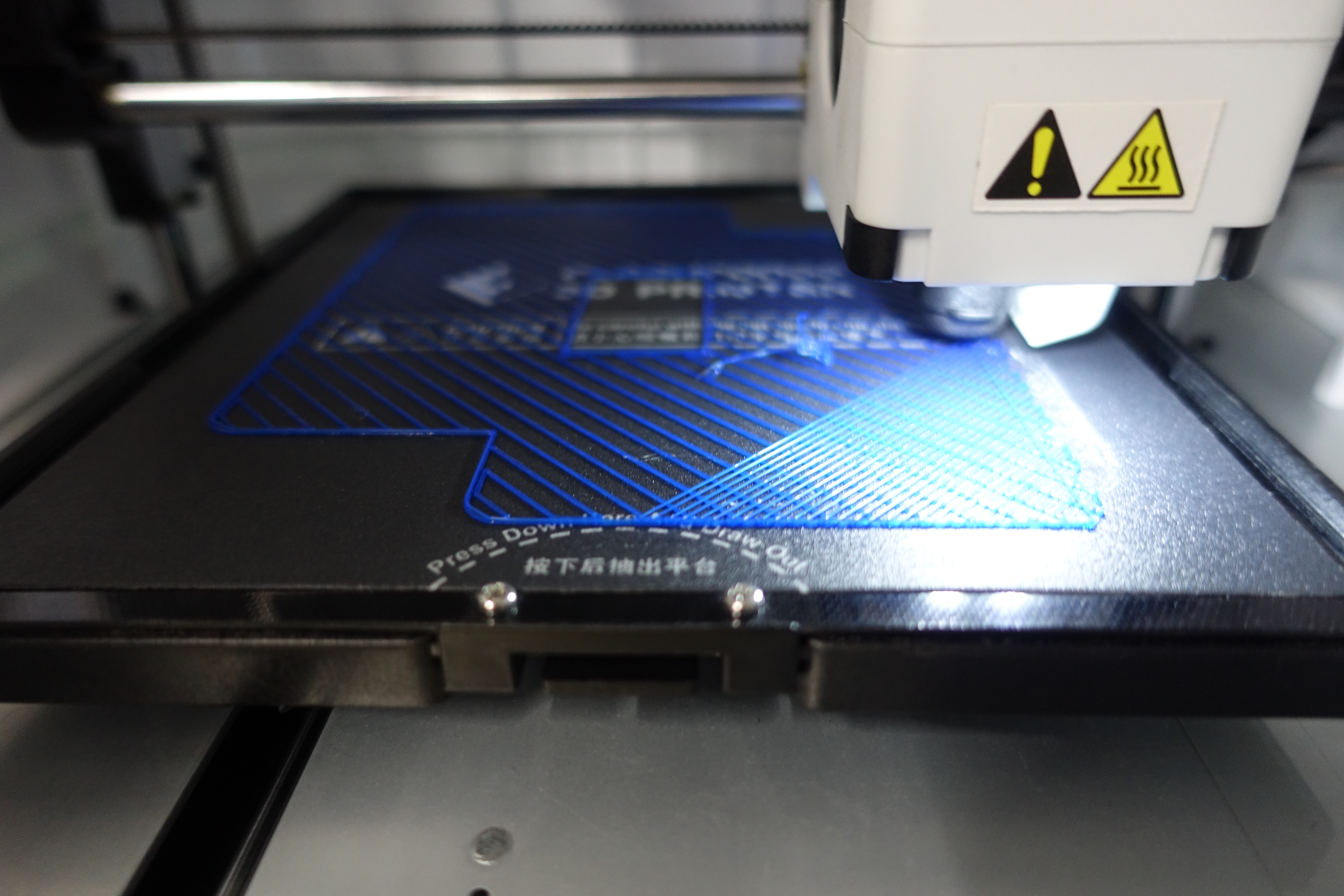

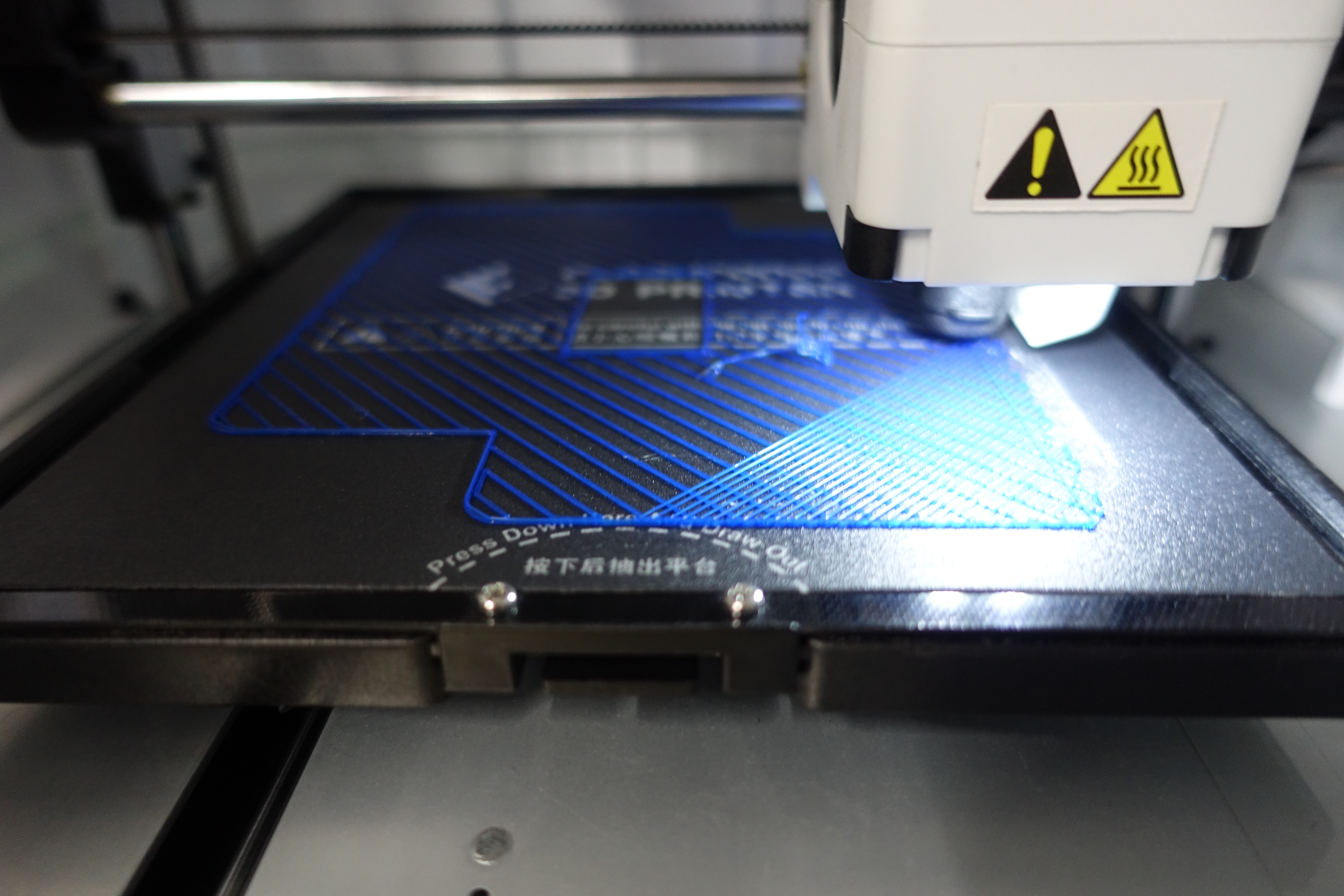

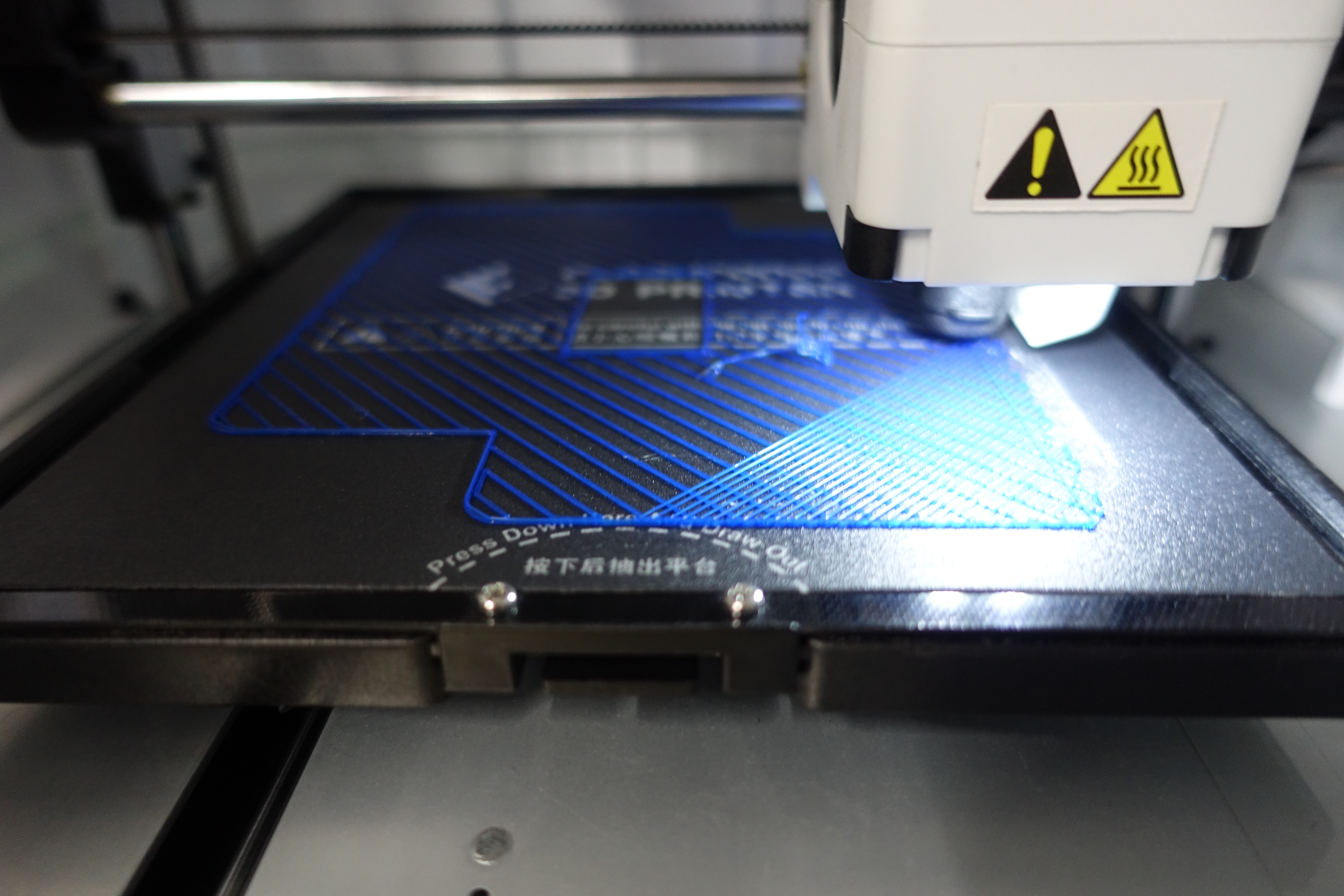

The 3D printer puts the melted filament Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. on the stage

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. on the stage A stage is the foundation on which moldings are printed in a 3D printer. by moving the stage

A stage is the foundation on which moldings are printed in a 3D printer. by moving the stage A stage is the foundation on which moldings are printed in a 3D printer. and nozzle

A stage is the foundation on which moldings are printed in a 3D printer. and nozzle A nozzle is a component that extrudes filament (resin) and prints it on the stage. to the XY axes. The filament

A nozzle is a component that extrudes filament (resin) and prints it on the stage. to the XY axes. The filament Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. will be solidified by air outside and form a solid layer.

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. will be solidified by air outside and form a solid layer.

Place: Dengiken's club room

▲Picture of printing layers made with a 3D printer.

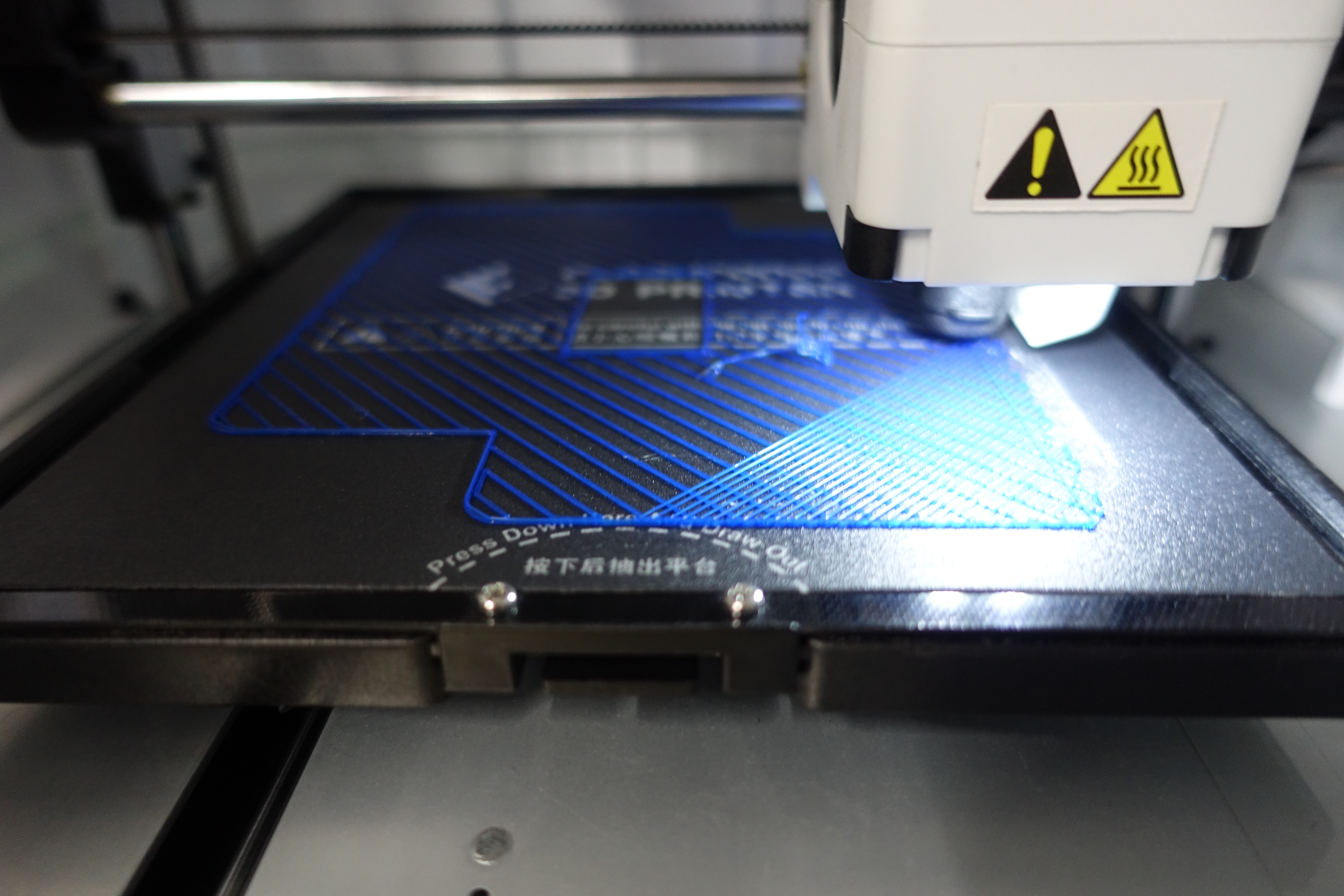

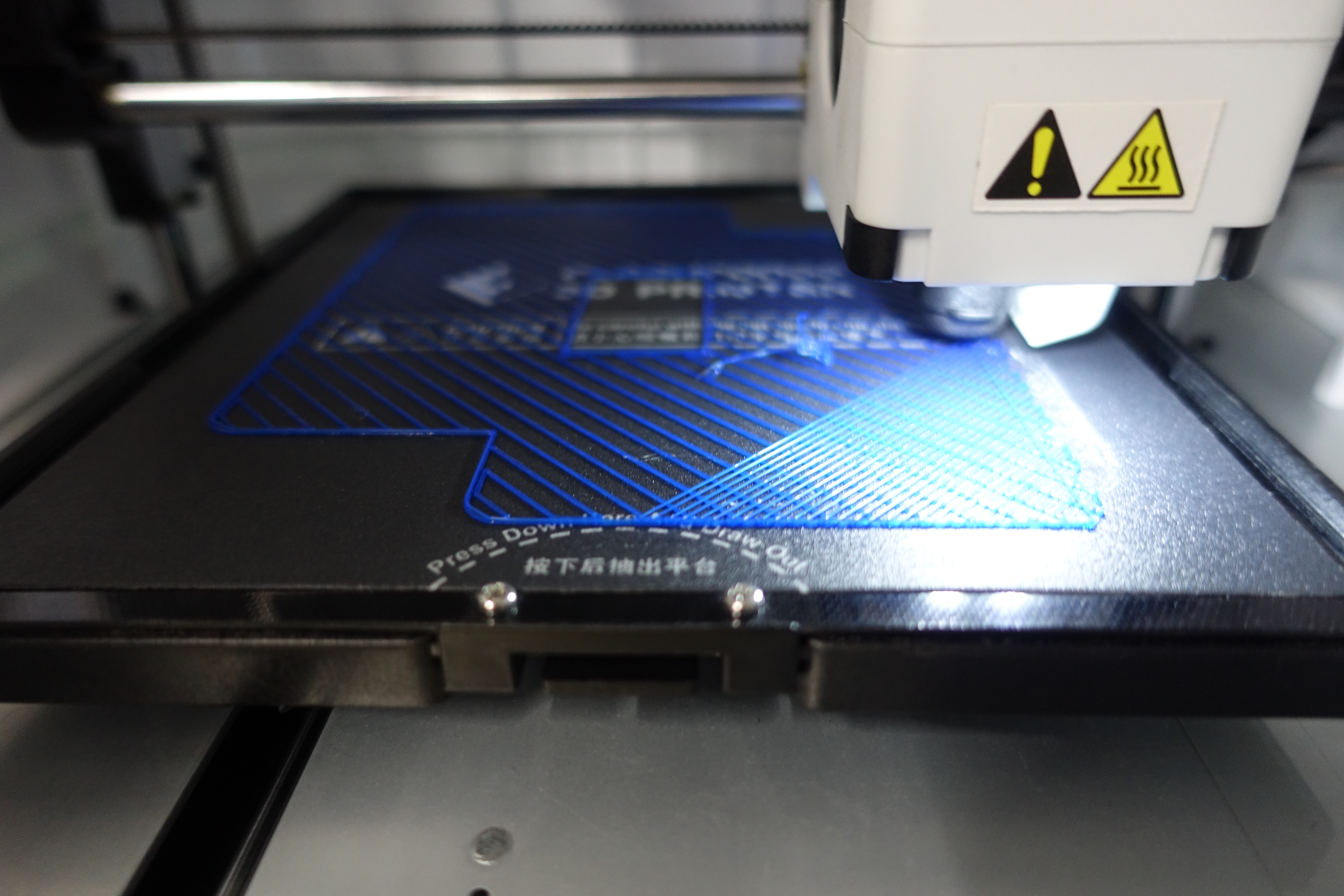

The 3D printer stacks each formed layer by moving the stage A stage is the foundation on which moldings are printed in a 3D printer. and nozzle

A stage is the foundation on which moldings are printed in a 3D printer. and nozzle A nozzle is a component that extrudes filament (resin) and prints it on the stage. to Z-axis while printing the filament

A nozzle is a component that extrudes filament (resin) and prints it on the stage. to Z-axis while printing the filament Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle..

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle..

Place: Dengiken's club room

▲Picture of stacking layers made with a 3D printer.

The thickness of each layer is called layer resolution Layer resolution is the thickness of each layer of the 3D model. The smaller the thickness is, the more accurate the printing will be. and the value determines the performance of the 3D printer.

Layer resolution is the thickness of each layer of the 3D model. The smaller the thickness is, the more accurate the printing will be. and the value determines the performance of the 3D printer.

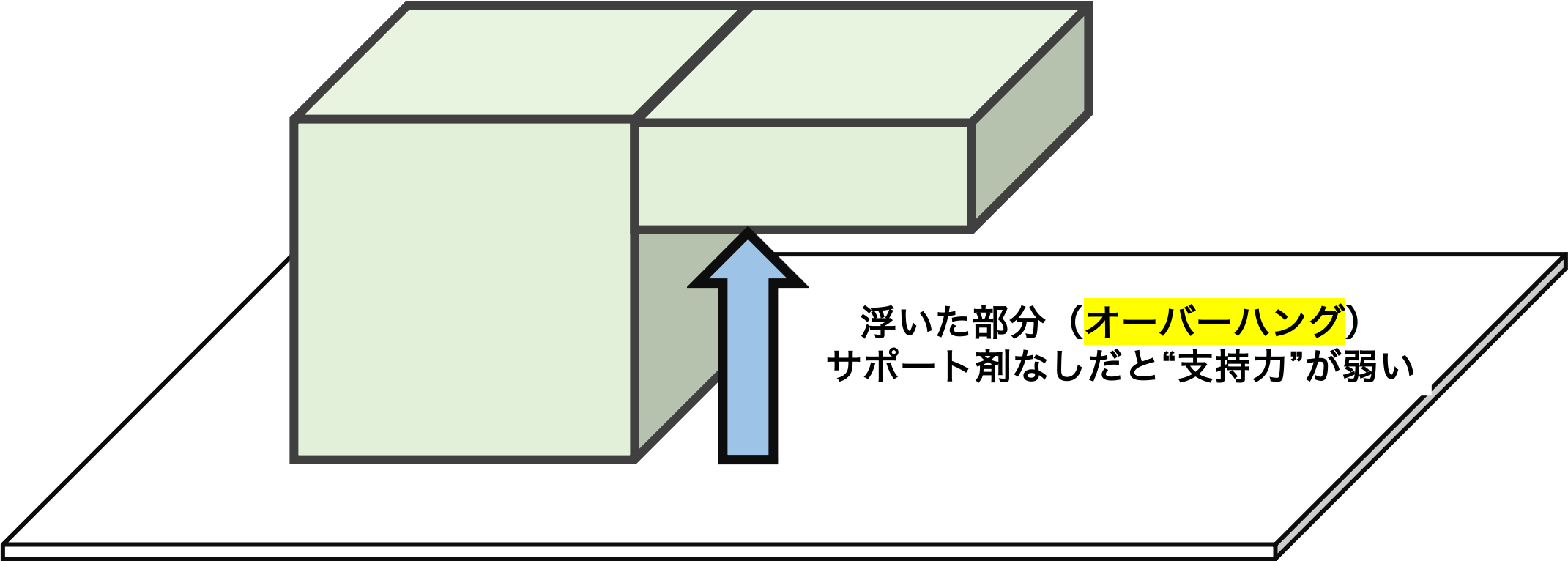

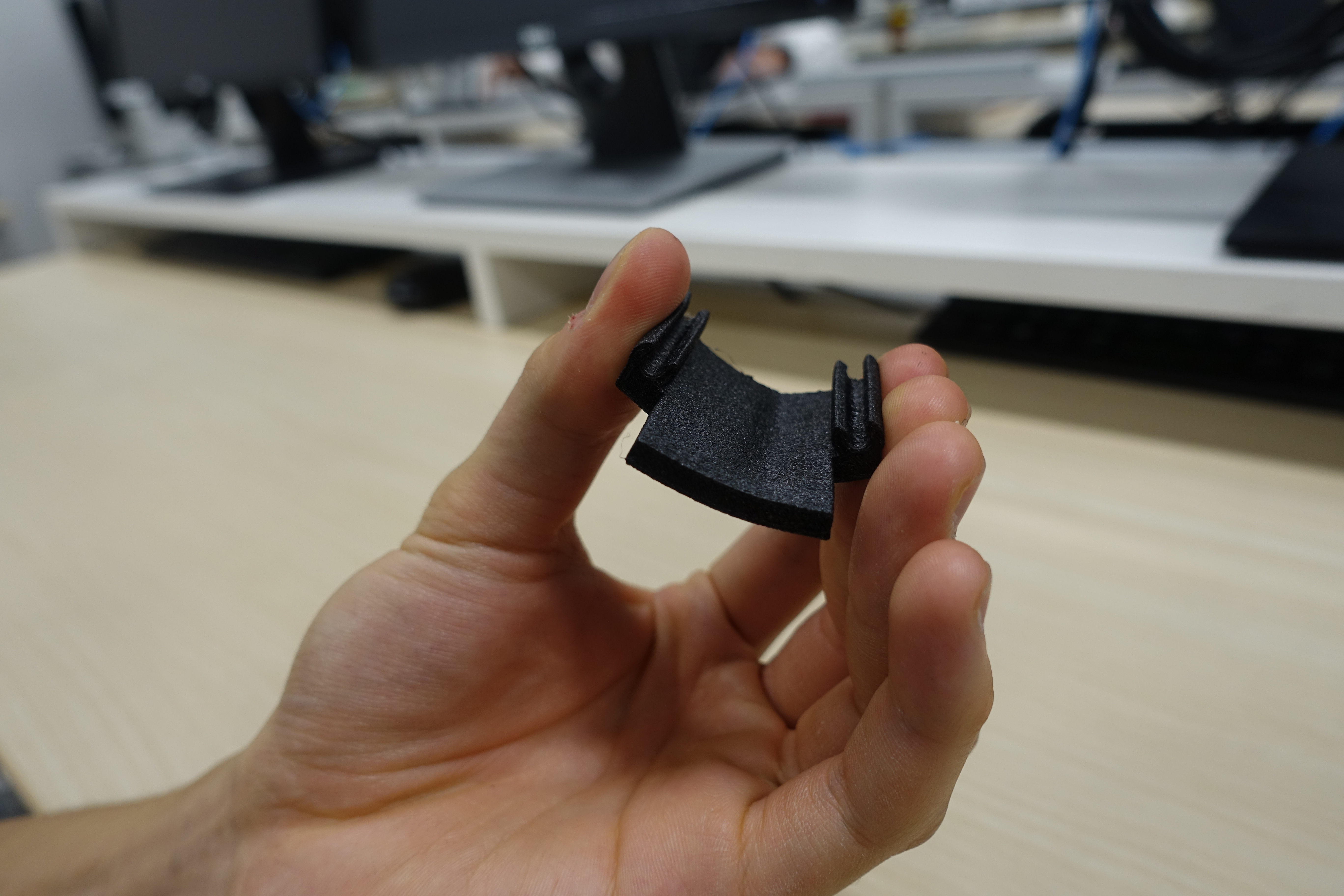

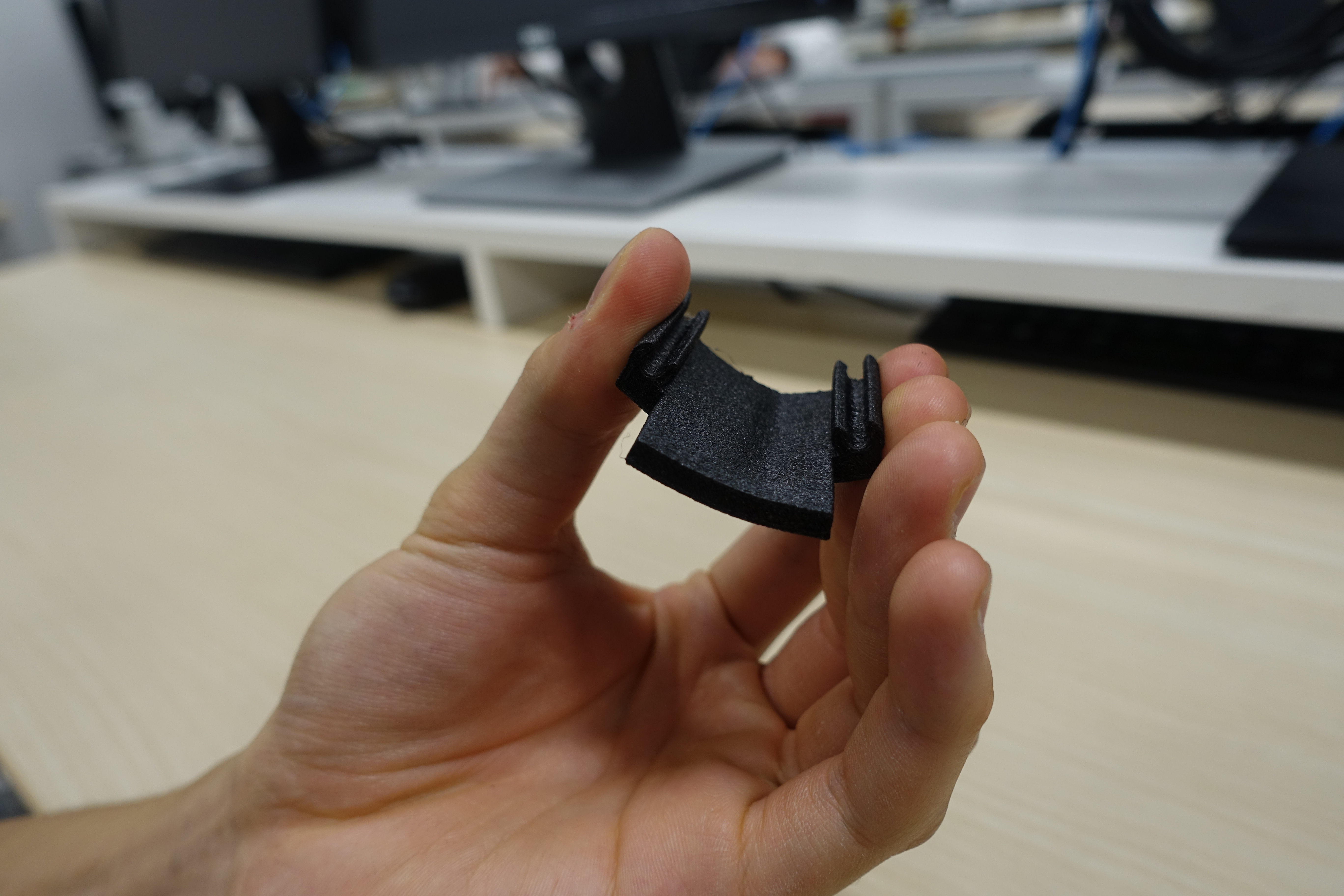

When overhangs An overhangs is an area in a modeling object that is floating in the air without support. Support structures is required when printing moldings. (floating) happen, we make support structures

An overhangs is an area in a modeling object that is floating in the air without support. Support structures is required when printing moldings. (floating) happen, we make support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. for printing. Then, we remove them after we finish printing.

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. for printing. Then, we remove them after we finish printing.

Place: Dengiken's club room

▲Picture of removing support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling..

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling..

In the case of a dual extruderA dual extruder refers to a printer with multiple heads. It is used in Fused Filament Fabrication and MultiJet Printing and can use multiple resins at the same time. 3D printer, we can remove support structures Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. more cleanly by using water-soluble filament

Support structures is a pillar printed between the hollow part (overhang) and the stage to prevent extruded filaments from floating during modeling. more cleanly by using water-soluble filament Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle..

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle..

Place: 3D Solution Center

▲Water-soluble filament Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. (BVOH)

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. (BVOH)

This is how Fused Filament Fabrication prints 3D objects.

Do you know there are many kinds of filament Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle.?

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle.?

PLA is made from agricultural products, which are weak. But they don't emit strange smells and can be handled easily. The filaments Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. are more inexpensive than other types.

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. are more inexpensive than other types.

ABS is the most common filament Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle., like PLA. Warping often happens because ABS has a high heat shrinkage rate. However, ABS is very sturdy and inexpensive compared to other types.

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle., like PLA. Warping often happens because ABS has a high heat shrinkage rate. However, ABS is very sturdy and inexpensive compared to other types.

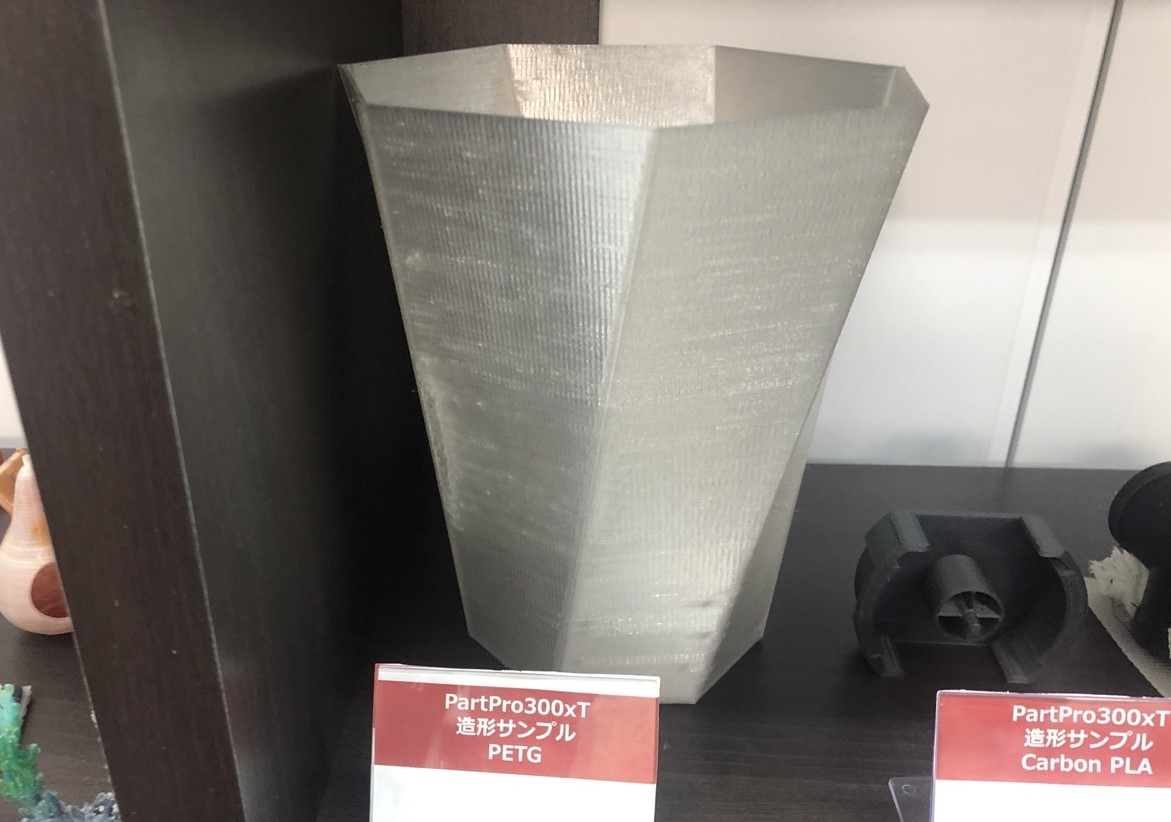

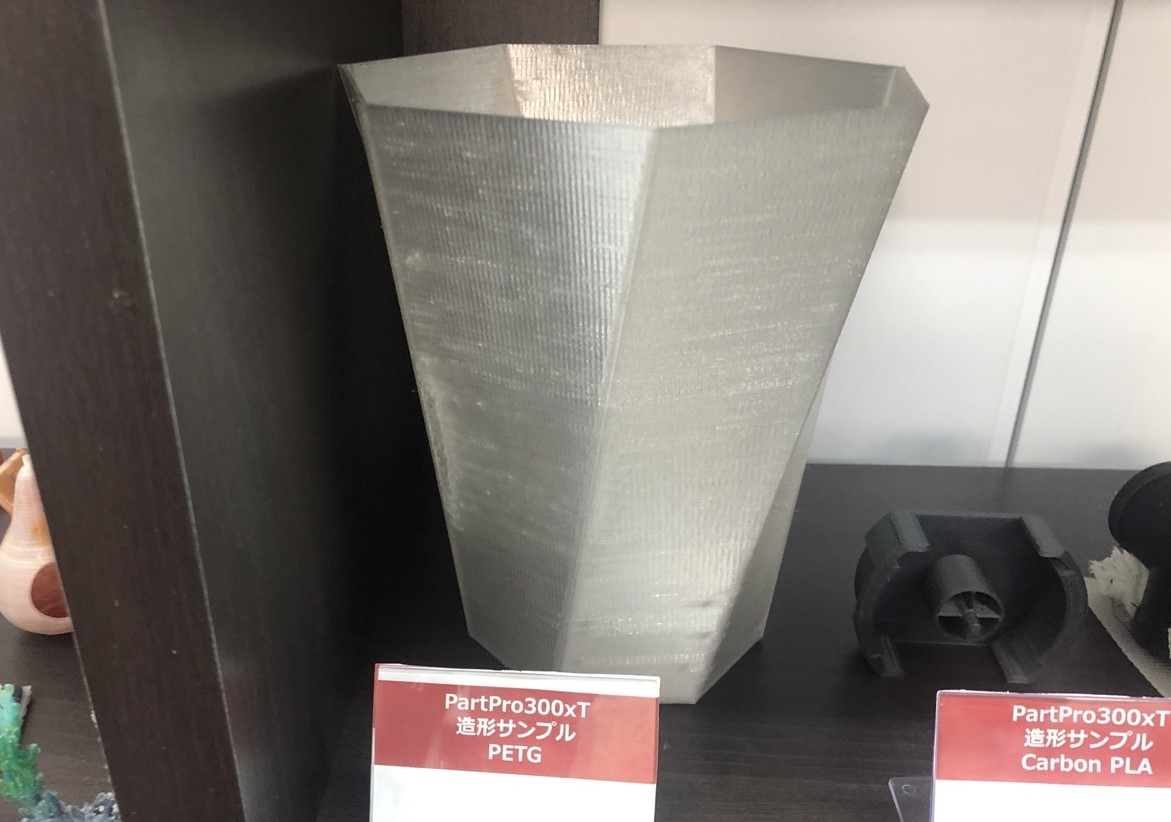

PETG is made from the resin used in plastic bottles and improved for a specific purpose. Adjusting temperature while printing is difficult, but PETG is excellent in terms of hygiene and thermal resistance.

TPU is a rubber-like filament Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle., which is difficult to use. The advantage is we can print flexible and resilient 3D objects.

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle., which is difficult to use. The advantage is we can print flexible and resilient 3D objects.

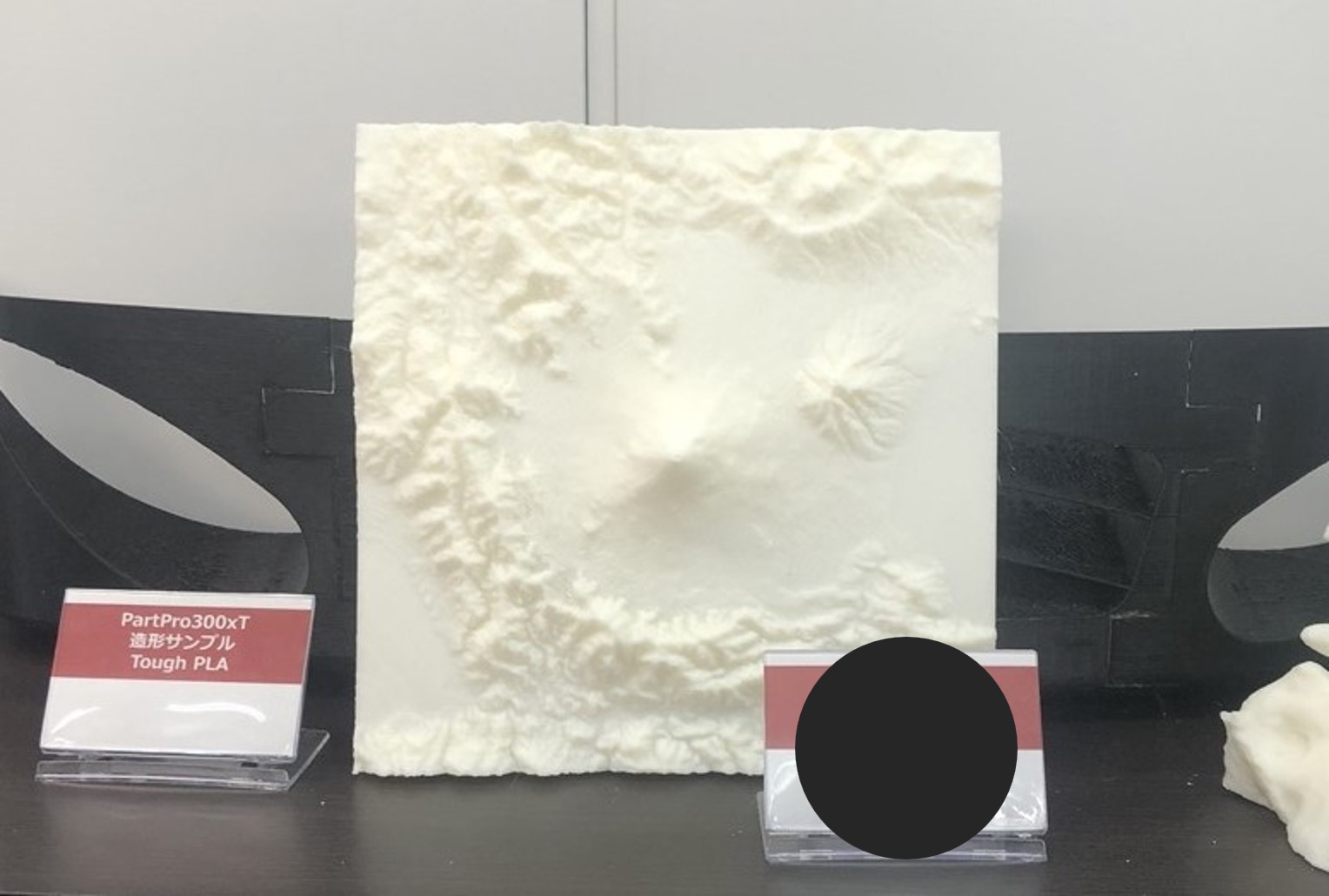

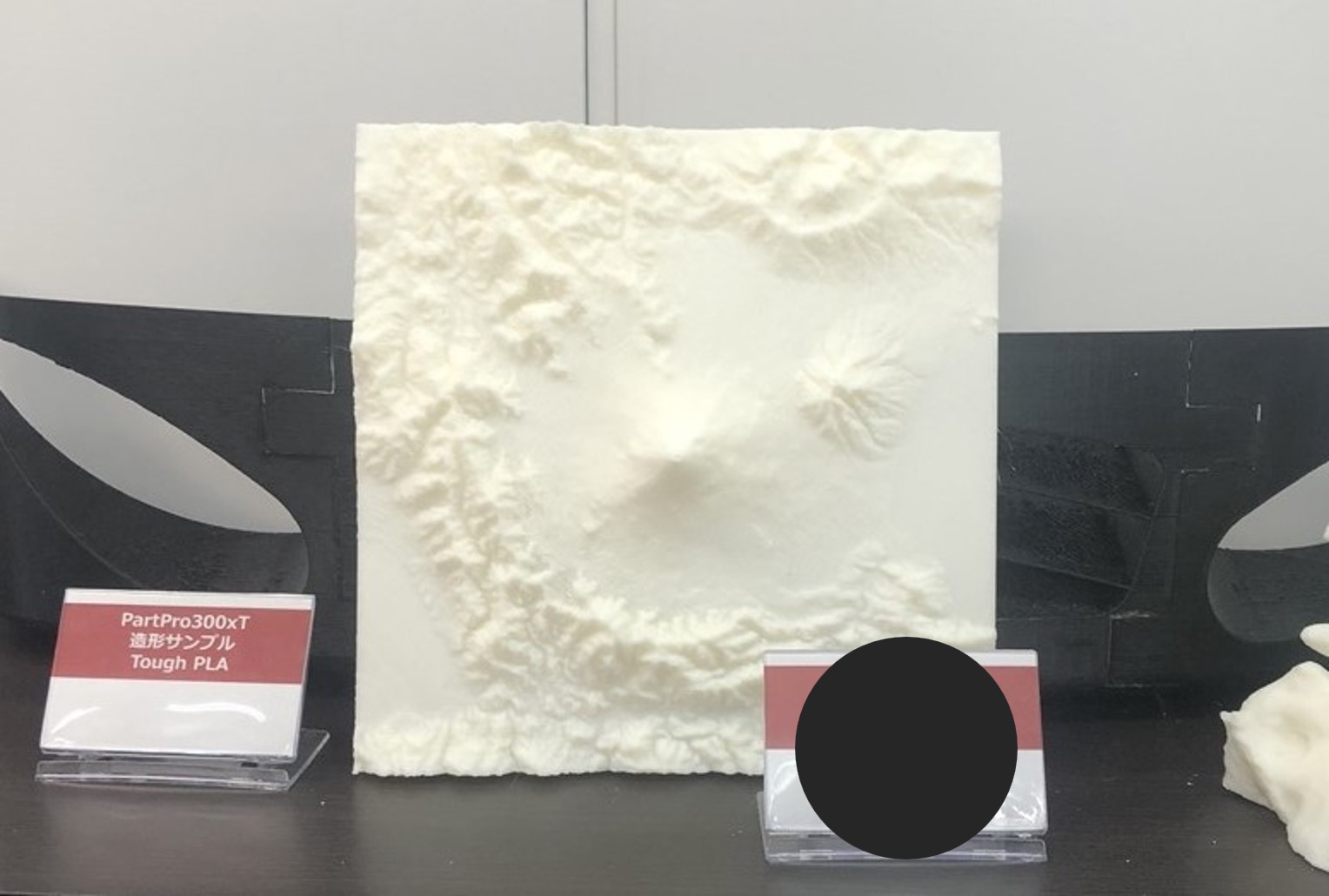

Place: 3D Solution Center

PLA

Place: 3D Solution Center

ABS

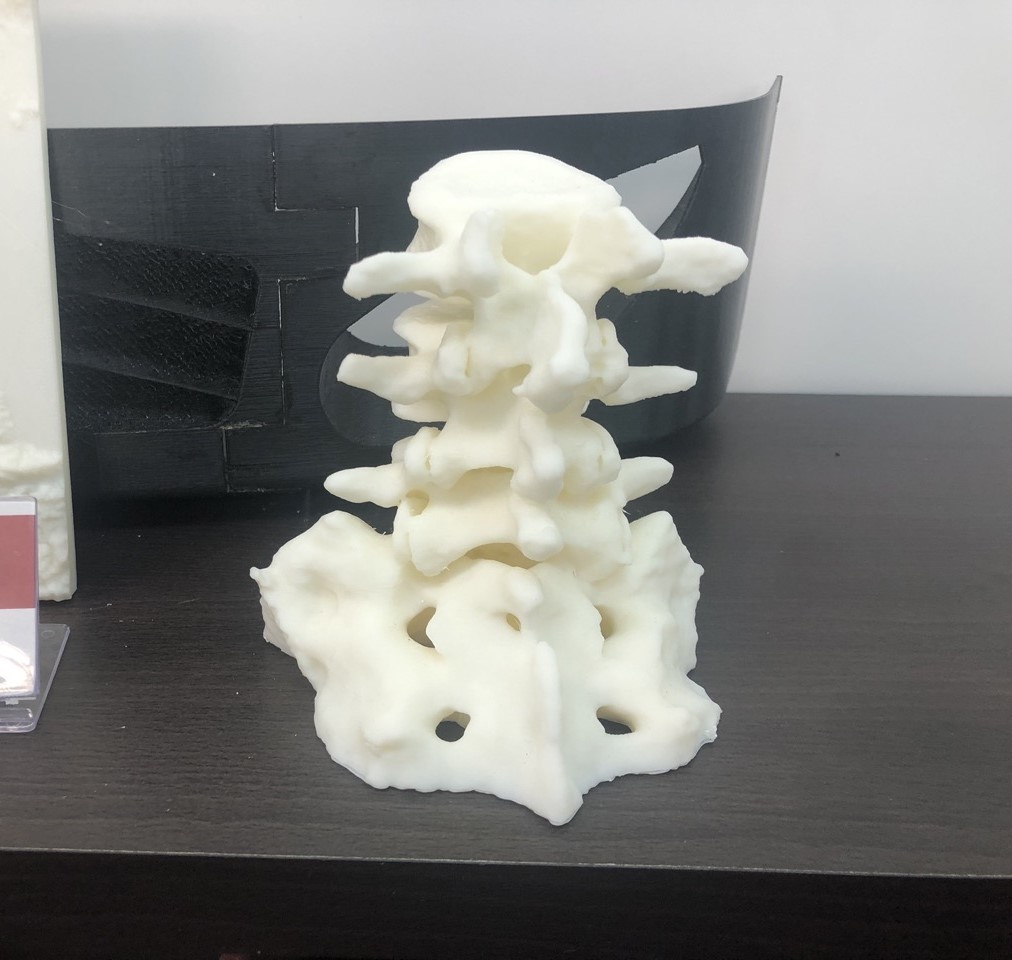

Place: 3D Solution Center

PETG

Place: Dengiken's club room

TPU

▲Picture of objects made from each resin

We will introduce the features of Fused Filament Fabrication.

Fused Filament Fabrication is safe as the filament Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. are not harmful. The disadvantage is the nozzle

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. are not harmful. The disadvantage is the nozzle A nozzle is a component that extrudes filament (resin) and prints it on the stage. becomes very hot. However, you don't have to worry if you use a printer model with a cover.

A nozzle is a component that extrudes filament (resin) and prints it on the stage. becomes very hot. However, you don't have to worry if you use a printer model with a cover.

Compared to other methods of printing, we can purchase printers at a low cost. Filament Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. are also affordable. Fused Filament Fabrication has a significant advantage in the long run.

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. are also affordable. Fused Filament Fabrication has a significant advantage in the long run.

Place: Dengiken's club room

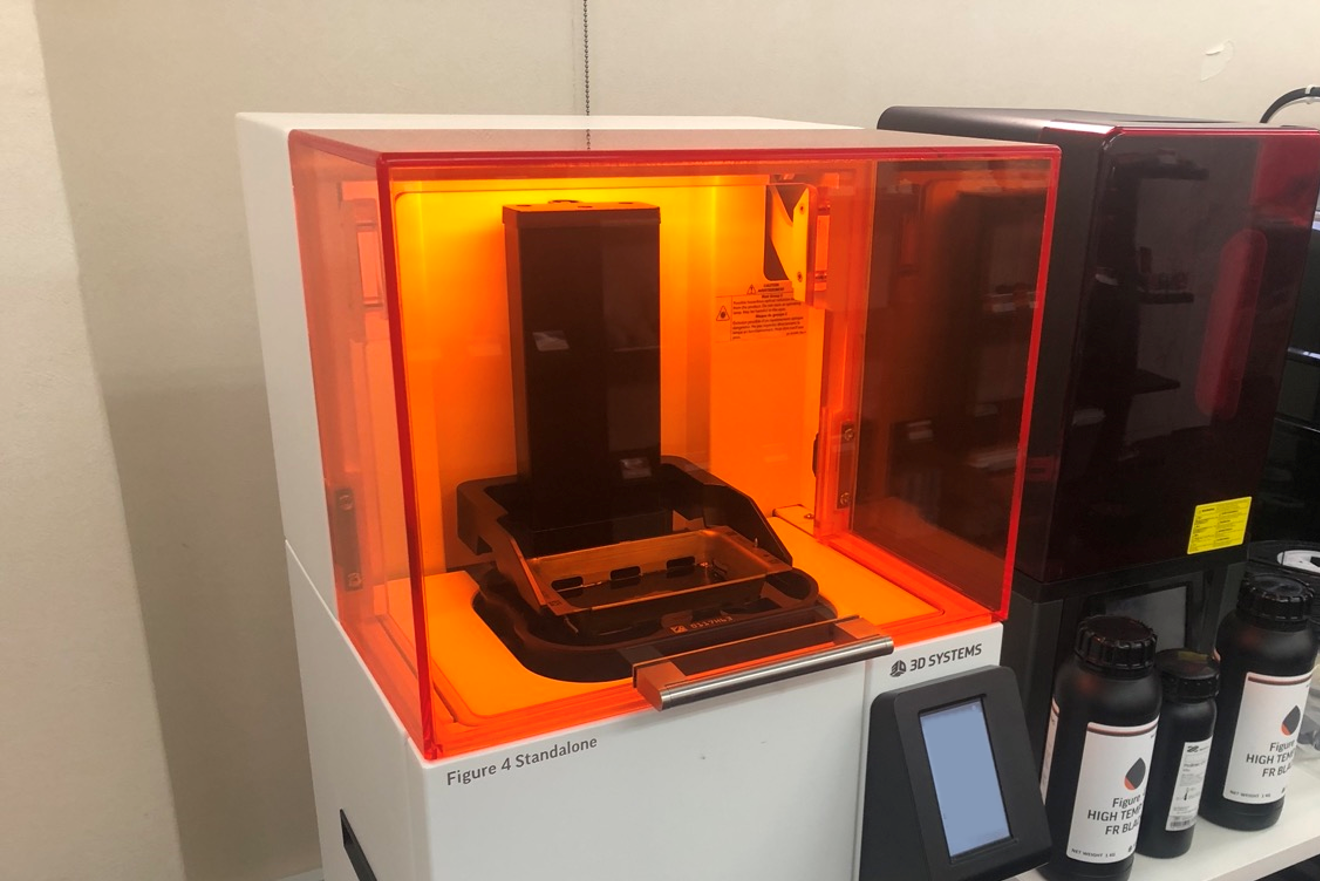

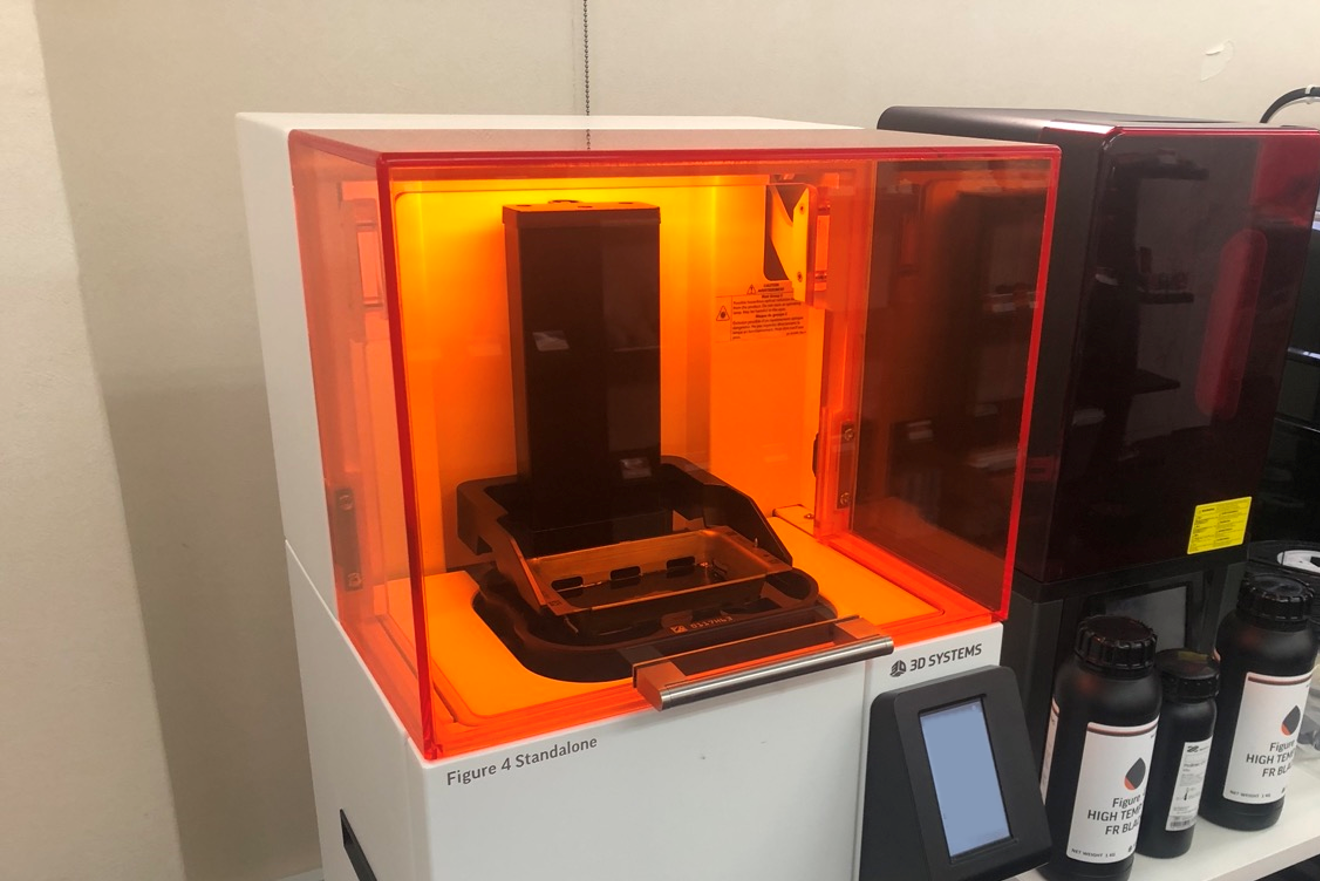

Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser.. The device prints from the bottom, and there is little effect on its weight. The picture shows an example of objects made with the device: a trophy that consists of a foundation, column, and figurine.

Stereolithography is a method that draws each layer and stacks it by solidifying liquid resin with a UV laser.. The device prints from the bottom, and there is little effect on its weight. The picture shows an example of objects made with the device: a trophy that consists of a foundation, column, and figurine.

Since its expiration in 2009, manufacturers have developed various kinds of products, and we have various choices of products. The prices vary from cheap ones to expensive ones.

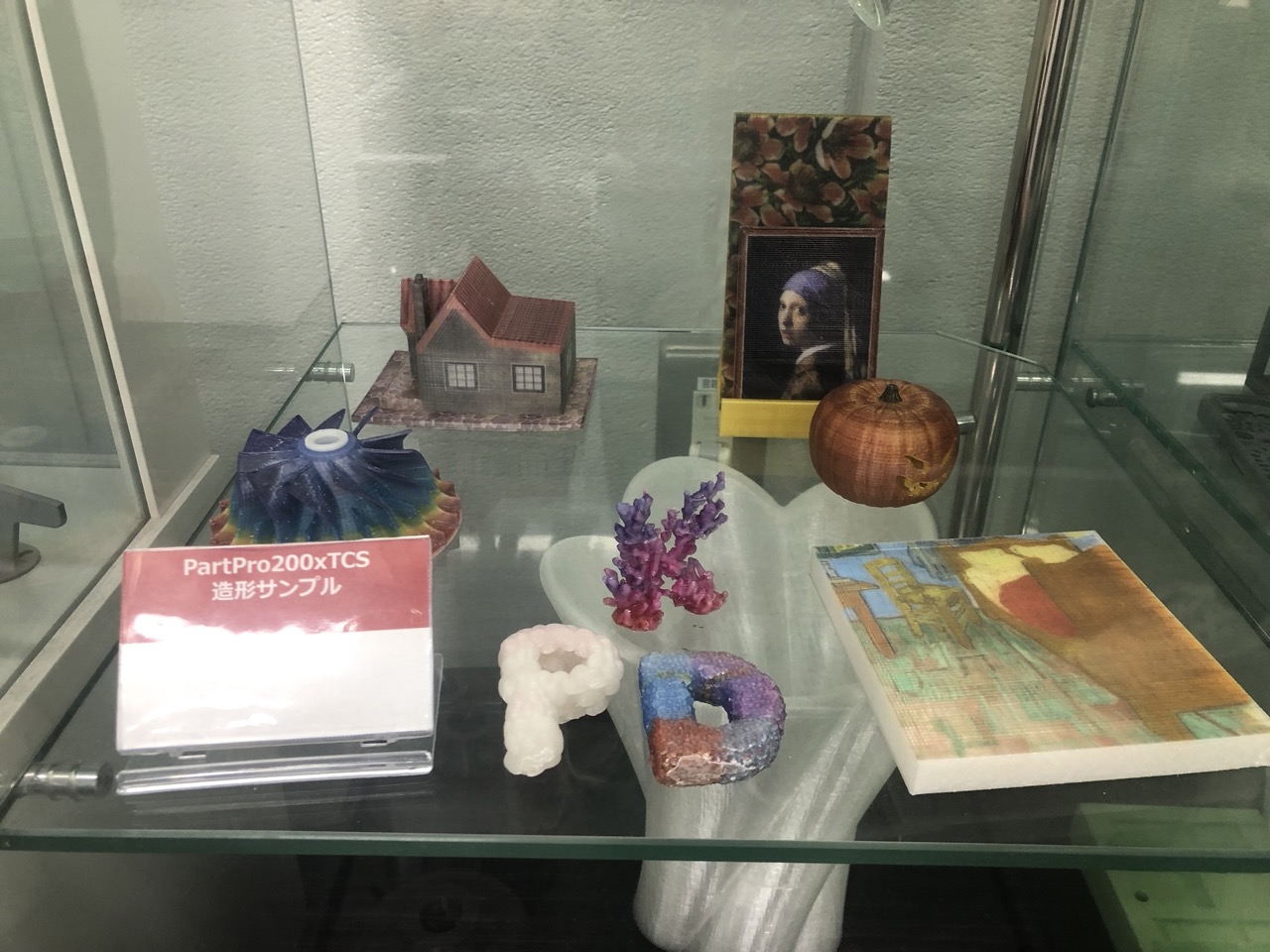

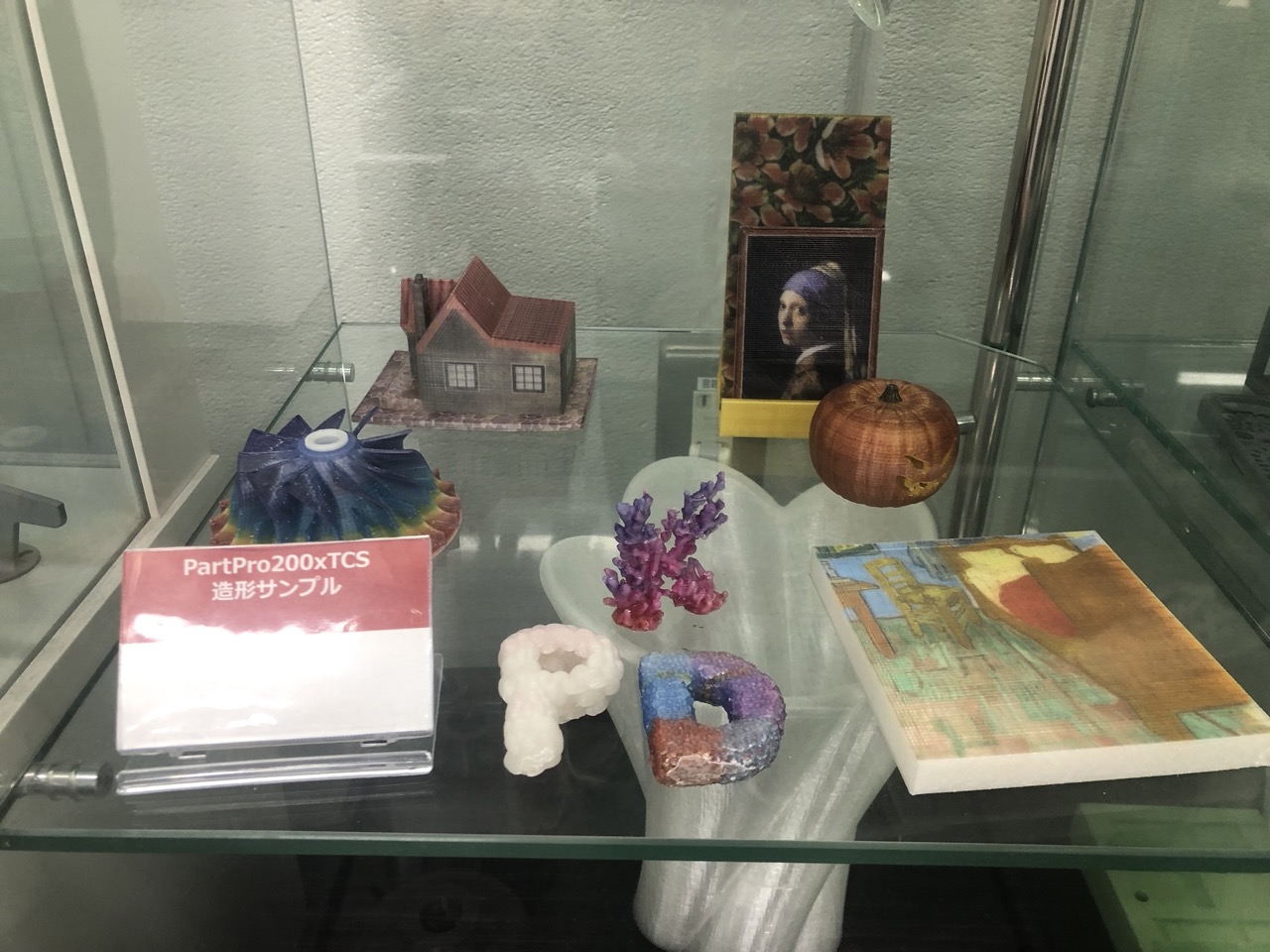

Some products of this type can print full-color objects by painting CMYKCMYK refers to the four colors cyan, magenta, yellow, and black. They are used as primary colors to represent full color in subtractive mixing such as printing. ink on each layer.

Place: 3D Solution Center

▲Full-color objects

Fused Filament Fabrication has some disadvantages, such as rough surfaces and low resolution caused by the layer resolution Layer resolution is the thickness of each layer of the 3D model. The smaller the thickness is, the more accurate the printing will be..

Layer resolution is the thickness of each layer of the 3D model. The smaller the thickness is, the more accurate the printing will be..

Place: 3D Solution Center

▲The picture shows the different resolutions caused by the layer resolution Layer resolution is the thickness of each layer of the 3D model. The smaller the thickness is, the more accurate the printing will be..

Layer resolution is the thickness of each layer of the 3D model. The smaller the thickness is, the more accurate the printing will be..

Warping is one of the disadvantages of Fused Filament Fabrication. Distortion happens when filament Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. are solidified. How much the objects distort depends on what kind of filament

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. are solidified. How much the objects distort depends on what kind of filament Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. we use.

Filament is a tubular resin used in the Fused Filament Fabrication, which can be wound onto a reel and is easy to handle. we use.

Fused Filament Fabrication is mainstream as a home-use 3D printer A home-use 3D printer is one intended for personal purchase. Although home-use 3D printers are less precise than industrial-use printers, they are less expensive, with some printers costing less than 50,000 yen. because it is safe, we can buy printers at a low cost, and we have a lot of choices.

A home-use 3D printer is one intended for personal purchase. Although home-use 3D printers are less precise than industrial-use printers, they are less expensive, with some printers costing less than 50,000 yen. because it is safe, we can buy printers at a low cost, and we have a lot of choices.

Although Fused Filament Fabrication has the disadvantage of printing quality, the advantages outweigh the disadvantages as the printers are affordable, etc..

These are the features of Fused Filament Fabrication.

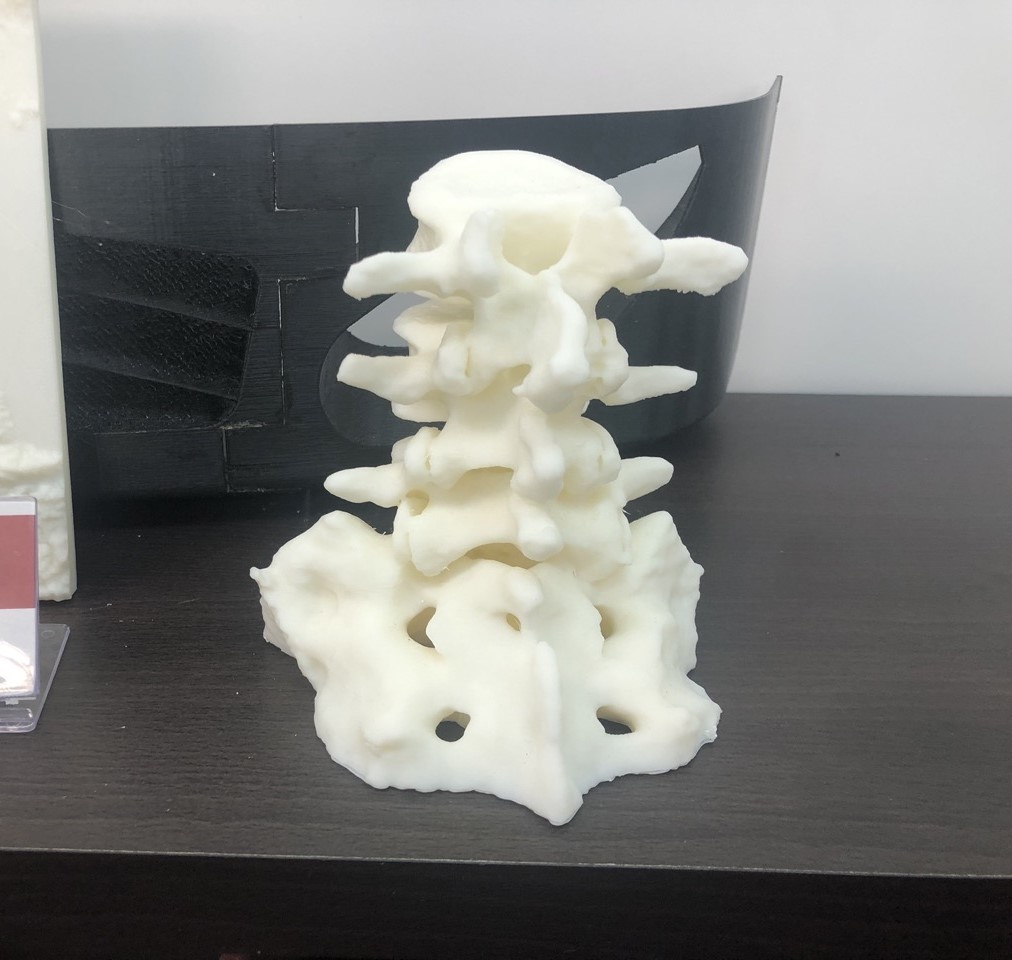

We will show some pictures of Fused Filament Fabrication and its printed objects.

This is a 3D printer placed in our club room.

Place: Dengiken's club room

filament

Place: Dengiken's club room

Picture of printing layer made with a 3D

Place: Dengiken's club room

Picture of stacking layer made with a 3D

Place: Dengiken's club room

Picture of removing support structures

Place: Dengiken's club room

Water-soluble filament (BVOH)

Place: 3D Solution Center

Picture of an object printed with PLA

Place: 3D Solution Center

Picture of an object printed with ABS

Place: 3D Solution Center

Picture of an object printed with PETG

Place: 3D Solution Center

Picture of an object printed with TPU

Place: Dengiken's club room

Picture of a trophy printed with Fused Filament Fabrication

Place: Dengiken's club room

Full-color objects printed with a 3D printer.

Place: 3D Solution Center

The picture shows the different resolutions caused by the layer resolution.

Place: 3D Solution Center